Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

The hum, whine, or grinding sound from an electric motor can be more than simply aggravating. This intro to noise in electrical motors will aid you recognize the possible causes . We’ll take a look at why your electric motor may be making so much noise and what you can do concerning it. This short article is worth reading since a quiet electric motor is typically a much healthier, more efficient electric motor . Understanding noise and resonance in electric equipment can save you money and time.

When we discuss noise in an electric motor , we mean any noise that the electric motor makes while it’s running that isn’t desired. Electric motors are developed to transform electrical power into mechanical movement, making things revolve . Some sound is regular, however when it becomes loud or changes, that’s when we call it motor noise . This noise is generally an indicator that something within the motor isn’t quite right. The sounds can be different. You might listen to a low hum, a shrill whine, or perhaps clanking sounds. Each kind of noise in an electric motor can point to different possible causes . Consider it like an automobile; a new noise typically means it’s time to look under the hood. The same goes for an electric motor . Comprehending these sounds is the very first step. These electric motors are complex electric equipment . This noise created by an electric motor can be air-borne noise , which takes a trip through the air to our ears. It can also be structure-borne, suggesting the resonance takes a trip through the electric motor mountings and the device it’s linked to. Commonly, vibration and noise go together. The noise level matters as well; a very quiet electric motor could still have trouble if the kind of noise is brand-new.

You could assume a little motor noise is not a huge problem. But, electric motor noise can tell us a whole lot. Initially, it can be a warning sign. Increased noise in electric motors commonly indicates there’s more deterioration taking place inside the motor . This can be trouble with a bearing , the rotor , or the stator . If you ignore it, the electric motor can fail. This can stop production and cost a lot of cash. Second, a loud electric motor can be negative for individuals working close by. Loud, continuous noise in electrical settings can be demanding. It can even damage hearing with time, especially if it’s a high frequency that falls within the range of human hearing . This is why there are guidelines regarding safe noise level limits in several offices. An electric motor that is as loud may not meet these regulations. Lastly, the vibration that commonly includes motor noise can damage not just the electric motor itself, but also the devices it’s attached to. This vibration can loosen bolts, crack components, or cause various other issues. So, taking note of noise in an electric motor helps maintain the entire device running efficiently and securely. This is a key part of any electric motor application .

Yes, magnetic noise is a very typical source of noise , specifically in AC motors like squirrel-cage motors. This type of noise in an electric motor comes from the magnetic forces at work inside the motor . The stator (the stationary part) and the rotor (the component that rotates) have magnetic fields. These fields push and pull to make the rotor rotate . Often, these magnetic forces can make parts of the electric motor , like the stator core or the winding , vibrate. This resonance produces sound waves, which we hear as magnetic noise or electro-magnetic noise . It often seems like a hum or a whine. The number of poles in the electric motor and the layout of the rotor and stator can affect how much magnetic noise is made. A four-pole electric motor may appear different from a two-pole one. Points like an uneven air gap between the rotor and stator , or issues with the power supply (like a high harmonic content from a variable frequency drive ), can make magnetic noise even worse. The forces in the air gap are really strong, and if they are not balanced, they can create greater noise and resonance . This is an essential area electrical engineers check out when designing a quiet electric motor .

Windage noise is one more kind of motor noise you might listen to. This noise in an electric motor is triggered by air movement. Think about it like the sound a fan makes. Several electric motors , especially open electric motors or those that go for high speeds , have a cooling fan . This fan is attached to the rotor shaft and aids to cool the electric motor by blowing air over it. The cooling fan itself can develop windage noise as its blades cut through the air. The faster the electric motor rotates, the more air the fan relocates, and the louder the windage noise can be. The form of the fan blades and the design of the motor housing can additionally affect this noise level . This type of noise is normally much more noticeable in high-speed electric motor applications. Occasionally, other components of the rotating electrical machines can create windage noise as well, not just the primary cooling fan . If the rotor itself is not smooth or has parts standing out, it can stir up the air as it spins, contributing to the windage noise . While some windage noise is typical for an electric motor with a fan, an abrupt rise or an adjustment in the noise can suggest a loose fan blade or an obstruction in the air path. This is one of the most usual kinds of noise in electrical motors that are fan-cooled.

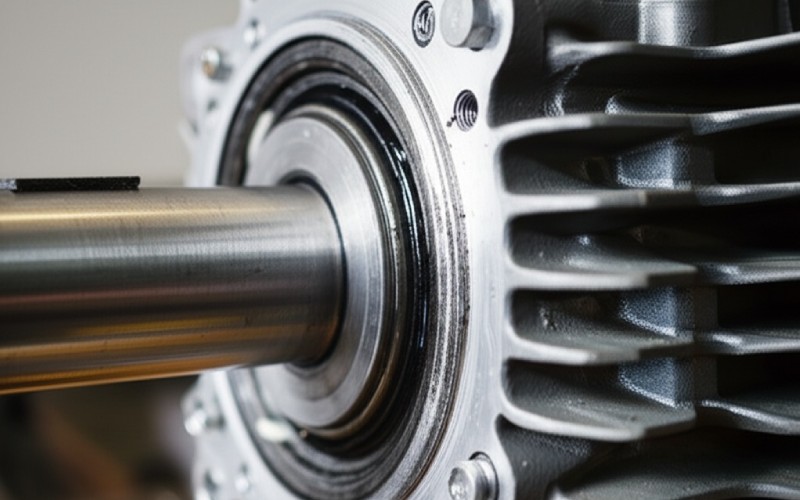

Mechanical noise is a really typical kind of noise in an electric motor . This noise comes from physical parts of the electric motor rubbing, hitting, or vibrating against each other. The main sources of noise here are often the bearings. A bearing allows the rotor to rotate smoothly. But if a bearing is worn, damaged, or lacks sufficient lubrication , it can make a great deal of noise in an electric motor . This could sound like grinding, roaring, or squealing. Another source of noise can be an unbalance in the rotor . If the rotor is not flawlessly balanced, it will vibrate as it spins. This resonance can shake the whole electric motor and develop a loud, grumbling mechanical noise . Consider exactly how a washing machine shakes if the clothing is not expanded equally– it’s a comparable concept. This resonance puts additional stress on the bearing system as well. Various other resources of mechanical noise in an electric motor include loose parts. For example, if the motor housing is loose, or if something is rubbing versus the rotor or fan, it will certainly make sounds. In some cases, the shaft of the electric motor may be bent slightly. This can likewise trigger resonance and mechanical noise . Finding these noise sources is essential to fixing the trouble. A worn bearing is a frequent offender.

Learning specifically where the noise in an electric motor is coming from can be difficult. Determining the source of noise often requires a systematic method . The initial step is to pay attention very carefully. What does the motor noise seem like? Is it a hum, a whine, a click, or a rumble? When does it happen? Does the noise in an electric motor change when the electric motor accelerates or decreases, or when it’s under load? We can use devices to help. An easy listening stick (like a screwdriver with the handle to your ear and the idea on the electric motor — beware!) can help identify where the vibration and noise in electric motors are strongest. Special tools used for measuring sound and resonance can offer much more precise readings of the amplitude and frequency content of the noise produced . This is often the work of a technician. An additional good action is to examine if the noise in an electric motor changes if you disconnect the electric motor from what it’s driving. If the noise quits, the issue could be with the driven machine, not the electric motor itself. If the electric motor is running by itself and still loud, then the source of noise is most likely within the motor . This methodical investigative method assists narrow down the possible causes .

Yes, loose parts are most definitely typical causes of resonance and raised noise in an electric motor . An electric motor has numerous parts, and if any one of them come to be loosened, they can rattle or shake. For example, a loose stator core can be a big problem. The stator is constructed from thin metal laminations stacked together. If these sheets are not held securely, they can vibrate and develop magnetic noise or a mechanical humming noise. Mounting bolts is another point to inspect. If the electric motor is not bolted down tightly to its base, it can vibrate a whole lot. This resonance not only makes noise but can also harm the electric motor and the device it is connected to. Also little parts, like a loosened cover or a loose terminal box, can trigger frustrating rattles. In some cases, parts inside the motor can end up being loosened, like a winding that is not secured correctly. This can be more challenging to discover. The resonance from loosened parts can also trigger various other troubles in time, like making a bearing wear out quicker. So, if you hear a brand-new rattling or humming noise in an electric motor , checking for loose parts is an excellent very first step. This sort of noise in a motor can have a significant impact on its lifespan.

The air gap in an electric motor is the very small space between the rotor and the stator . This air gap is very essential for the electric motor to work. But, it can additionally be a source of noise , specifically magnetic noise . The magnetic forces that make the rotor spin act across this air gap . If the air gap is not the exact same all the way around– if there is an uneven air gap — then the magnetic forces will be out of balance. This unequal pull can create the rotor to shake. It can additionally make the stator to deform slightly. This vibration and distortion develop noise in an electric motor . An uneven air gap can take place if a bearing is worn, permitting the rotor to sag, or if the electric motor was not manufactured perfectly. Even with a perfect air gap , the magnetic fields transforming as the rotor spins can create the surfaces of the rotor and stator facing the air gap to vibrate. This is a form of magnetic noise . The layout of the rotor-stator combination, including the number of slots in the rotor and stator , affects these forces and the resulting noise level . Keeping the air gap appropriate and uniform is important for a quiet, reliable electric motor . It’s a crucial part of electrical machines .

There are numerous means to minimize noise in an electric motor , going for effective noise reduction . One of the usual approaches is to make certain the electric motor is mounted properly. This suggests a strong base and good alignment with the maker it drives. This can minimize resonance , which frequently brings about much less airborne noise . For magnetic noise , developers can change points like the form of the stator slots or the rotor bars. Skewing of the rotor slots or stator slots is a common technique. Skewing means the slots are angled a bit along the length of the rotor or stator . This assists to smooth out the magnetic forces in the air gap and decrease noise in electrical motors . The choice of products for the stator and rotor can likewise play a part. For mechanical noise , making sure bearings are in good shape and well-lubricated is key. A good lubricant reduces friction in the bearing . Balancing the rotor thoroughly also minimizes vibration and noise. For windage noise from the cooling fan , developers can use quieter fan blade shapes or enclosures around the motor . Occasionally, making use of a totally encased, non-ventilated electric motor (if cooling permits) or a separate, quieter cooling system can be designed to reduce this certain noise in an electric motor . Some motor drives can also be adjusted to reduce noise by changing the switching frequency, but this might affect efficiency. This electric motor is typically quieter after such changes.

In some cases, simple solutions are inadequate, and motor repair is required to solve noise in an electric motor . If you hear abrupt, loud motor noise , like grinding or banging, quit the electric motor as soon as possible if you can do so securely. This might suggest a major issue, like a failed bearing or something broken inside the motor . Continuing to run the electric motor might cause a lot more damage. If the noise level from your electric motor has gradually gotten worse over time, this could additionally point to the demand for motor repair . It may be a bearing wearing, a winding problem, or a loose stator core worsening. Trying to deal with these problems on your own can be difficult if you do not have the right devices or experience. Finding the source of noise can be more challenging than correcting it, yet both require treatment. A professional motor repair shop can take the electric motor apart. They can examine the stator , rotor , bearings, and winding . They can replace worn parts, like a bearing , rebalance the rotor , and repair any issues with the winding or stator . Sometimes, the motor is often more difficult to repair than to replace, particularly for smaller electrical motors . But for bigger or special electric motors , repair is typically an excellent selection. Following NEMA standards for repairs is also vital for these electrical machines . This attention to detail in an electric motor can prevent future increased noise .