Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Have you ever wondered how big machines move, lift heavy things, or spin fast? Often, it comes down to a special kind of engine or machine called a motor. In the world of power, two big players are the hydraulic motor and the electric motor. Both help make things work, but they do it in very different ways. Knowing the difference between electric and hydraulic systems is key to picking the best tool for the job. This article will help you understand these mighty machines, from how a pump works to the force they create. We’ll look at the good and bad points of each, so you can see why one might be a better choice for a certain task than the other. If you work with machinery or just like to know how things operate, this guide is for you!

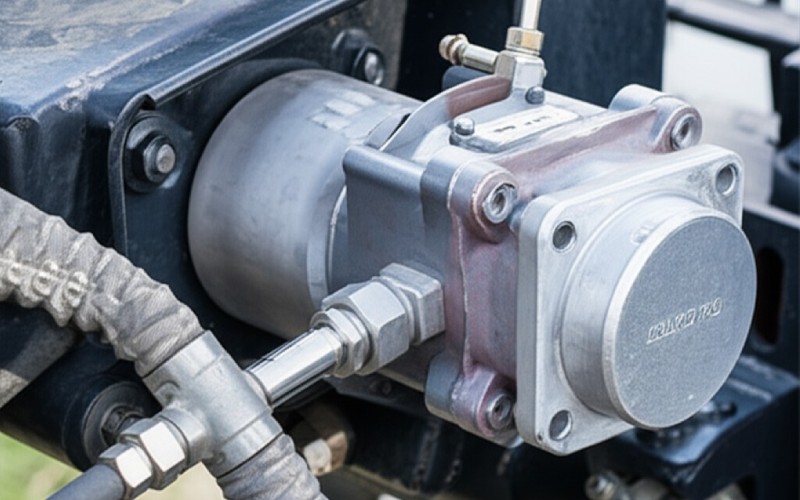

A hydraulic motor is a machine that uses the power of moving liquid to create motion. Think of it like a water wheel, but instead of water, it uses a special oil, or hydraulic fluid, under great pressure. This fluid pushes against parts inside the hydraulic motor, causing them to rotate. It’s a very strong way to make things move.

In a typical hydraulic system, a hydraulic pump pushes the hydraulic fluid through pipes. This fluid then goes to the hydraulic motor. As the fluid pushes internal parts, like gears or pistons, the motor turns. This turning motion can then be used to power a crane, a digging machine, or a robot arm. Hydraulic systems require sealed lines to make sure the fluid stays under pressure and flow and doesn’t leak out. These hydraulic designs are known for being very strong.

An electric motor is very common; you probably have many in your home, from your fan to your washing machine. An electric motor changes electrical energy into movement. It uses magnets to do this. Inside the motor, there are coils of wire. When electricity flows through these coils, they become temporary magnets. These magnets then push and pull against other magnets, making the motor’s shaft rotate. This spinning force is called torque.

The amount of torque an electric motor can make depends on how much electricity it uses and how strong its magnetic field is. For bigger jobs, you need a bigger electrical motor that can handle more amperage to create more torque and rotational force. Electric motors and hydraulic motors both aim to create motion, but their core energy conversion methods are very different.

The pump is like the heart of any hydraulic system. It’s what makes the hydraulic fluid move and build up pressure and flow. Without a pump, the hydraulic fluid would just sit there, and no power would be generated. The pump sucks the hydraulic fluid from a fluid reservoir and pushes it into the system’s pipes and hoses.

This pump creates the high pressure that then drives the hydraulic motor or hydraulic cylinder. The more powerful the pump, the more fluid it can move per minute, which is called the flow rate. This means more power for the hydraulic motor. Hydraulic systems require many parts, and the pump is one of the most important for creating hydraulic power.

Electric motors have many good points. They are often cleaner, as they don’t use messy fluids. They can be very precise, especially servo motors, which are electric motors that can be controlled very accurately. They are also quieter than hydraulic motors and need less upkeep. You just plug them in, and they work. They also don’t have issues like leakage that you might see with hydraulics.

However, there are cons of electric motors. For very heavy tasks, an electric motor might need to be much larger and heavier than a hydraulic motor to produce the same amount of high torque. This means they can take up more space. Also, if an electric motor gets overloaded, it can overheat and even burn out. Motors use electricity, and sometimes getting enough power to a very large electric motor can be a problem. This type of motor might also need a reduction gear to get the necessary power, which takes up more space.

Hydraulic motors are known for their raw strength. They can produce high torque in a much smaller package than an electric motor. This means they are great for applications requiring huge pushing or lifting power, like construction machines. Hydraulics are also very robust; they can handle very harsh conditions and overloads without breaking down easily, thanks to their release valves. The incompressible nature of hydraulic fluid means power is transferred very efficiently.

On the flip side, hydraulic motors have some drawbacks. They are often messy due to the hydraulic fluid, which can leak. This fluid also needs to be changed and kept clean, which adds to upkeep. Hydraulic systems require more parts, like the pump, fluid reservoir, and valves, which makes the whole setup more complex and sometimes more costly to install and maintain. They can also be noisy, and their energy conversion isn’t always as efficient as electric systems, especially at lower power settings. Many types of hydraulic motors exist, each with its own specific advantages and disadvantages.

The choice between an electric or hydraulic motor often comes down to the job at hand. If you need extreme strength and compact power, like for a bulldozer or a large press, a hydraulic motor is often the better choice. Hydraulics can generate power that is difficult for electrical systems to match in the same small space. They are very good for tasks that need constant high torque and can handle rough work environments.

On the other hand, for precision tasks, speed, or quiet operation, an electric motor shines. Think of robots in factories, medical equipment, or everyday appliances. Electric motors are also preferred when cleanliness is a must, like in food processing or clean rooms, because there’s no risk of leakage. The comparison between electric and hydraulic systems often highlights these key differences in application. For domestic and industrial uses, the type of motor really matters.

An actuator is a device that makes something move, often in a straight line, like pushing or pulling. A linear actuator converts power into a straight-line motion. When we talk about electric and hydraulic motors, we also see a difference between electric and hydraulic actuators.

An electric linear actuator often uses a motor to turn a lead screw, which then pushes or pulls a rod. They are very precise and good for positioning tasks. For hydraulic cylinder and piston type actuators, the hydraulic fluid pushes a piston pushing against a piston inside a cylinder. This creates a very strong linear force. Hydraulic cylinders are known as powerful actuators and are some of the strongest actuators available. The size of the cylinder directly relates to the torque and force they can produce.

When you look at motors and electric motors, you’ll often hear about motor series. This means different kinds of designs or families of motors made for specific jobs. For electric motors, you might hear about AC motors, DC motors, or servo motors. Each motor series has its own strengths. For example, servo motors are for very exact control, while large AC motors are for constant, powerful spinning.

For hydraulic motors, there are also types of hydraulic motors, like gear motors, vane motors, and piston motors. Piston motors, for instance, are known for their high efficiency and power density, making them suitable for applications requiring precise control even at high power levels. Knowing the motor series helps you pick the right one for the job, as some motor systems are better at certain speeds, torque, or efficiency.

Power density is how much power a motor can pack into a small space. This is where hydraulics often win. A hydraulic motor can deliver much smaller package and incredible high torque for its size. This power density is why heavy machinery uses hydraulics. They get a lot of muscle without being huge. The incompressible fluid allows for direct and strong force transmission.

Electric motors, while good, often need to be bigger to match the torque and force of a hydraulic motor. However, electric motors often have better energy efficiency, especially over a wide range of speeds. This means less electrical energy is wasted as heat. Hydraulic power systems lose some energy due to friction and leakage in the fluid lines, and in the pump itself. So, while hydraulic motors can complete very heavy tasks, electric motors might be more efficient in terms of energy use overall for less demanding jobs.

So, when do you pick hydraulic or electric? It’s really about the task. If you need raw, unmatched high torque in a compact space, especially for heavy lifting or pushing, a hydraulic motor is your go-to. Think of industrial uses where max load capacity is key. For example, a hydraulic motor can apply a torque that is 8-14 times what an electric motor of the same size might achieve.

If you need precision, speed control, cleanliness, or lower noise, and the torque requirements are not extreme, then an electric motor is likely the better fit. An electric motor may be 4-12 times smaller than a hydraulic motor for light duties. The pump for a hydraulic system might be 2-8 times larger than an electric motor itself in certain setups. Hydraulic systems require careful maintenance of the hydraulic fluid, whereas electric motors are typically lower upkeep. Pneumatic designs also exist, but that’s another story! Ultimately, your motor type choice will depend on a careful comparison between electric and hydraulic actuators and motor systems. Motors offer different things. Sometimes, even additional motors might be needed for a complex job. The motor must fit the application perfectly. The motor must be changed if it does not meet the requirements of the job.