Let Sino's Lamination Stacks Empower Your Project!

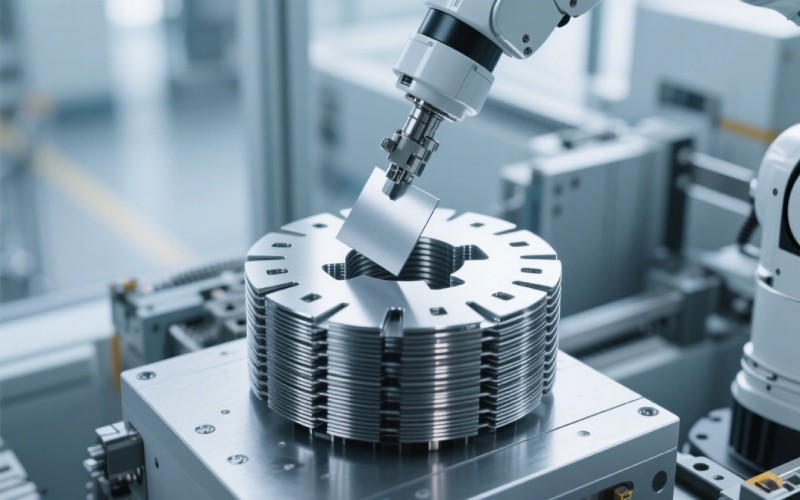

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Industries have been changing for a long time, and the change we see today in energy and travel is a complete game-changer. But behind the famous electric cars and giant wind turbines, there’s a material making it all happen: electrical steel. This isn’t your normal steel; it’s a high-tech, soft magnetic steel that is a vital material for the most important parts of the energy shift. This article will give you a closer look at electrical steel. I’ll explain what it is, why it’s so important for the energy and mobility revolution, and how makers are working to meet the growing need for this material with many uses. You’ll understand and value the complex science and building that goes into making this necessary part of our eco-friendly future.

The changes with the biggest effect are often the ones working quietly in the background. Electrical steel, also called silicon steel, is a great example. It’s a special kind of steel, a mix of iron and silicon, made just for its amazing magnetic abilities. Adding silicon, usually up to 6.5%, makes it harder for electricity to flow through the steel, which is a technical way of saying it cuts down on little circles of electricity that waste energy as heat. By reducing these, and also lowering the energy lost when the steel is magnetized and demagnetized (hysteresis losses), electrical steel becomes very good at its main job: guiding magnetic fields.

This high-tech material is usually made in thin, cold-rolled sheets, often less than 2mm thick. These sheets are then cut into shapes and stacked together to make the cores of electric devices like motors, generators, and transformers. The sheets have a special coating to stop even more wasted energy between them. It’s this mix of an iron-silicon material and a stacked structure that makes electrical steel the foundation of so many of today’s technologies. Without electrical steel, moving and using electricity as we do would be much harder and more wasteful.

The energy turnaround is a huge job, a move away from fossil fuels. A key part of this change is the need for very efficient ways to create, move, and use electricity from green sources. This is where electrical steel becomes very important. It’s a key material for the core parts that make the energy transition happen, like the generators in wind turbines and the transformers that manage our power system.

Picture a huge wind turbine out in the sea. The energy from its spinning blades has to be changed into electricity with very little waste. This is the job of the generator, and how well it works depends a lot on the quality of the electrical steel in its core. The soft magnetic steel gathers and strengthens the magnetic field inside the wind turbine generators, letting the spinning energy be changed into electric current very efficiently. In the same way, as we make more green energy in different places, we need a good way to move it. This is where transformers, built with cores of electrical steel, are used to increase or decrease voltage to move energy with low losses. Basically, without electrical steel, a successful energy turnaround would be almost impossible.

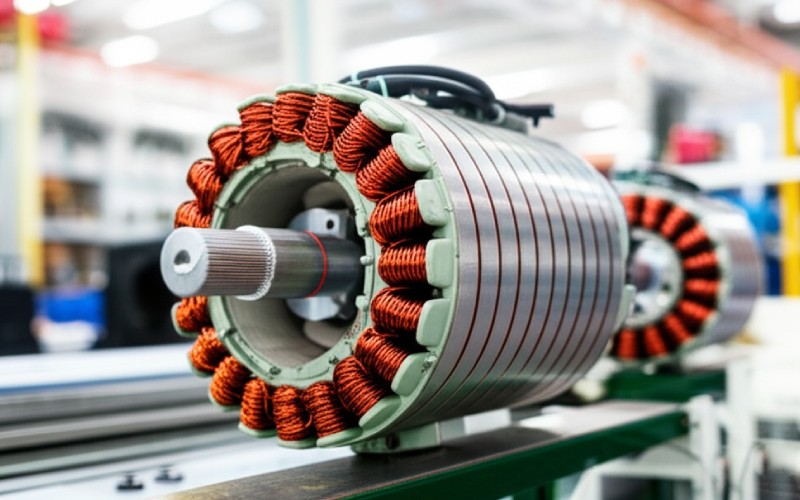

The growth of electric vehicles is one of the clearest signs of the energy and mobility revolution. And just like a heart pumps blood, the electric motor is what makes an electric car go. At the center of that motor, you will find electrical steel. To be specific, non-grain-oriented electrical steel is used to make the parts for the stator and rotor of an electric motor. This type of electrical steel has the same magnetic abilities in all directions, which is very important for spinning machines where the magnetic field is always changing.

The ability of electrical steel to easily support a magnetic field means a strong magnetic field can be made with a small amount of electricity. This leads directly to a better motor that wastes less energy. This high efficiency is extremely important in an electric vehicle because it affects how far the car can go on one charge. As electric car makers keep trying to make cars that go farther and perform better, the need for top-quality, high-efficiency electrical steel is growing fast. It’s true that the performance of an electric motor is closely connected to the quality of the electrical steel inside it.

Knowing “how” is as important as knowing “what.” A transformer is a piece of electrical equipment with no moving parts that moves electrical energy from one circuit to another using a magnetic field. Its main job is to increase or decrease voltage. For example, electricity is often sent over long distances at very high voltages to lose less energy. Then, a transformer lowers the voltage to a safer level for homes and businesses. The core of the transformer, which guides the magnetic field, is where electrical steel, specifically grain-oriented electrical steel, shows its great value.

Grain-oriented electrical steel is made in a way that lines up its internal structure, giving it better magnetic abilities in one direction. This makes it very good at guiding the magnetic field, which is exactly what a transformer needs to do its job with very little energy waste. Using high-quality electrical steel in transformer cores lets them work with stronger magnetic fields, which leads to lower running costs and better energy saving across the whole power system. As our energy supply becomes more spread out with more green energy, the job of efficient transformers in moving energy will only become more important.

The same solution doesn’t work for everything, and that’s true for electrical steel too. There are different “grades” of electrical steel, each made with certain features for different jobs. The two main types are grain-oriented (GO) and non-grain-oriented (NGO) electrical steel.

Grain-oriented electrical steel, with its lined-up structure, has great magnetic ability and low energy loss in one direction. This makes it the best grade for non-moving equipment like transformers, where the magnetic field direction is always the same and saving energy is very important. On the other hand, non-grain-oriented electrical steel has a random structure, which means its magnetic abilities are the same in all directions. This makes it the right choice for spinning machines like electric motors and generators, where the magnetic field is always changing. Besides these two main types, there are more grades in each group, often based on their thickness and how much energy they lose. This lets builders choose the right material for what they need.

In today’s competitive world, the best companies are the ones that work closely with their customers to give them custom solutions. Electrical steel makers are the same. They know that the needs of the energy and mobility revolution call for more than just standard products. That’s why top makers get into close teamwork and lasting relationships with their clients in the car and energy industries.

This teamwork approach helps them understand the exact needs of a project, whether it’s a powerful traction motor for an electric car or a huge transformer for the power grid. Through this teamwork, they can keep researching and making new solutions, finding new limits for what electrical steel can do. This could mean making new material mixes with better magnetic abilities, creating super-thin strip for high-frequency uses, or improving the production method to have less impact on the environment. This focus on making custom solutions makes sure the electrical steel being made is not just a material, but a technology that helps their customers succeed.

Making electrical steel is a complicated process that uses a lot of energy, and makers have several problems to solve. One of the biggest problems is the changing prices of raw materials, especially silicon and steel, which can greatly affect how much money is made. Also, the making process itself has environmental issues, and steelmakers are being pushed to lower their pollution and follow strict rules.

Another big challenge is the huge need for the product. The fast growth of the electric car market and the building of more green energy systems are creating a big increase in need for high-grade electrical steel that is hard to keep up with. Building more factories for electrical steel is a long and costly process, often taking many years to get new plants working. Also, there is a problem for non-grain oriented electrical steel where the growing needs for both thinner steel and higher efficiency are testing what today’s factories can do. Meeting this fast-growing need while also dealing with environmental issues is a top goal for every electrical steel maker.

The worldwide electrical steel market is expected to grow a lot, pushed by the very fast growth in electric cars and the rising use of green energy in our power systems. Some studies predict that the electrical steel used just for electric cars could be over 20% of the whole market by 2035. This huge need will surely encourage more new ideas in the field.

We can expect to see new electrical steel grades with even lower energy loss and better magnetic abilities, allowing for even more efficient motors and transformers. Research will also focus on making the production process more eco-friendly, with more focus on using recycled materials and cutting pollution from factories. The EU Ecodesign Directive will keep pushing for better energy efficiency, increasing the need for high-quality electrical steel that helps our customers meet these tough rules. The future of electrical steel will be about a constant search for better performance, more eco-friendly methods, and new ideas to meet the world’s growing energy needs.

Real progress has to be eco-friendly. For the electrical steel industry, this means dealing with the environmental effects of how it’s made. The good news is that steel can be recycled forever, which is a big plus when looking at its total environmental impact. The key to an eco-friendly future is in a few main areas. First, using more recycled steel to make electrical steel can greatly reduce pollution and the need for new, unused materials.

Second, the industry must keep investing in and start using cleaner ways to make things. This includes moving toward using green hydrogen in the steelmaking process, which could greatly reduce pollution. Companies like thyssenkrupp are already making progress here with their bluemint® steel. Lastly, a continued focus on making high-efficiency electrical steel is itself a help to being eco-friendly. The more efficient our motors, generators, and transformers are, the less energy we waste, and the smaller our total environmental impact becomes. By focusing on these areas, the electrical steel industry can make sure it stays a key part of a truly eco-friendly energy and mobility revolution.