Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

As China’s top manufacturer of lamination stacks, Sino knows how much a good engine lamination core can improve motors and generators. We focus completely on these important parts. We use China’s top position in world manufacturing, along with our deep technical knowledge, to make core laminations that meet the highest international standards. We want to be a partner you can trust, giving you the foundation for your drive motor and generator solutions.

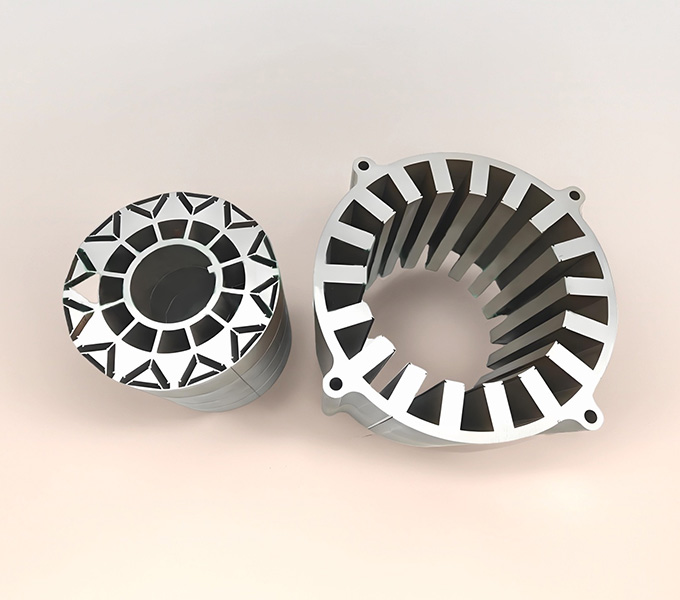

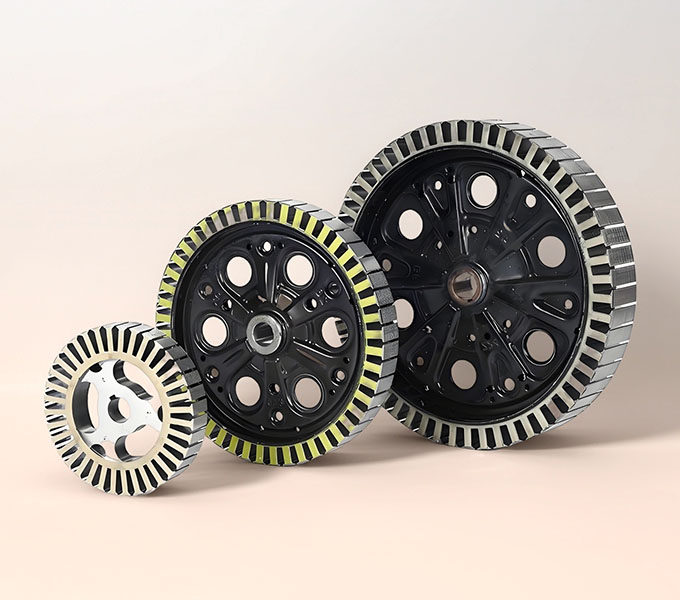

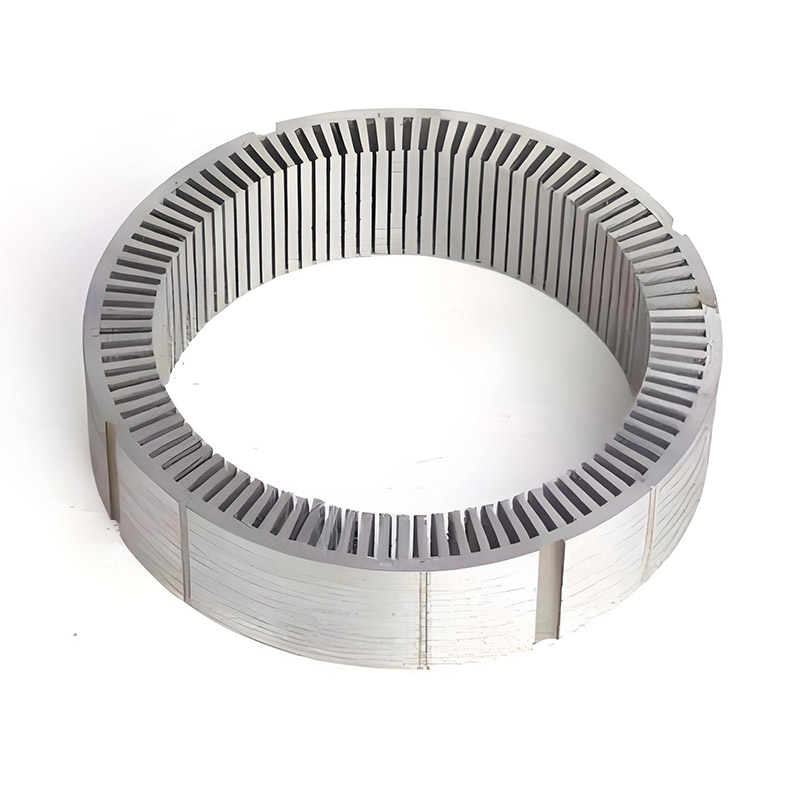

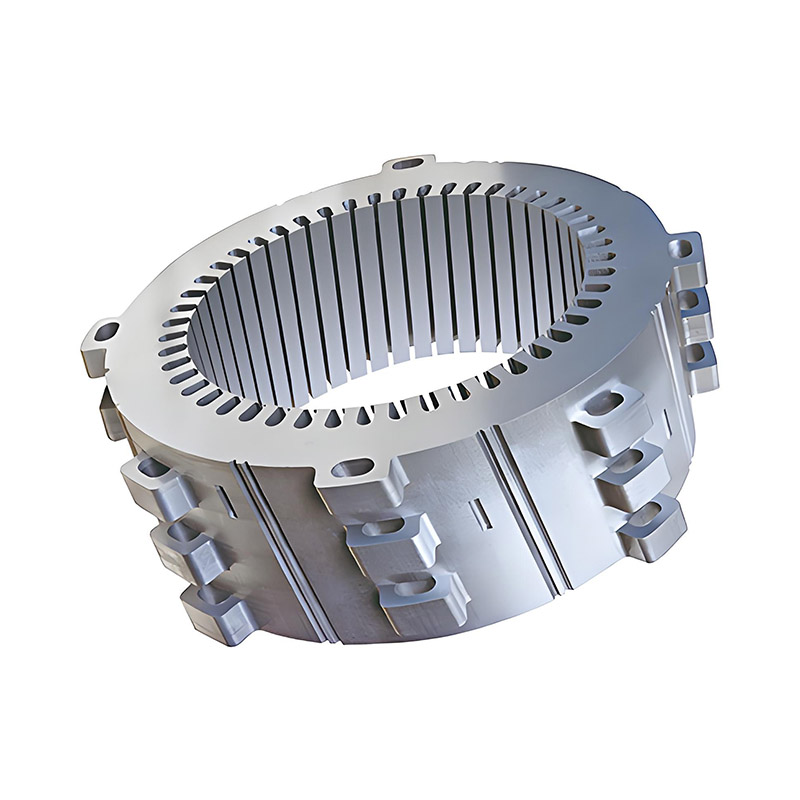

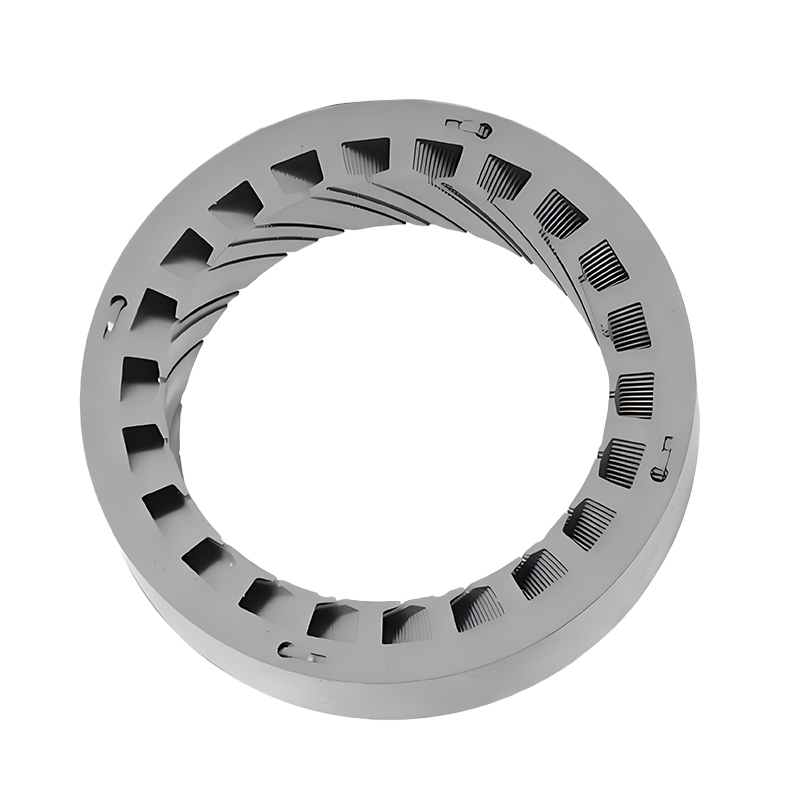

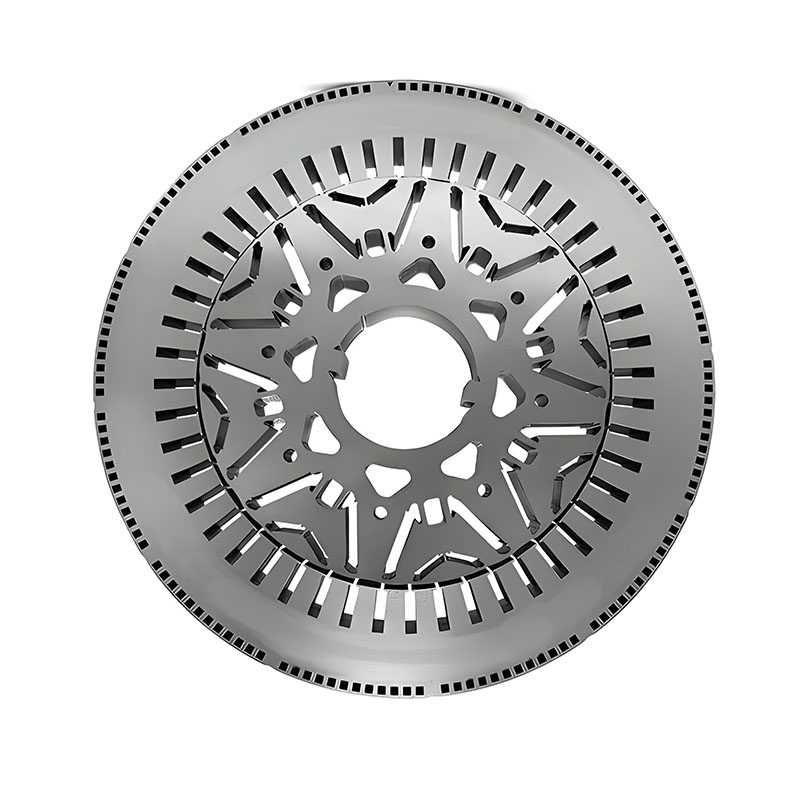

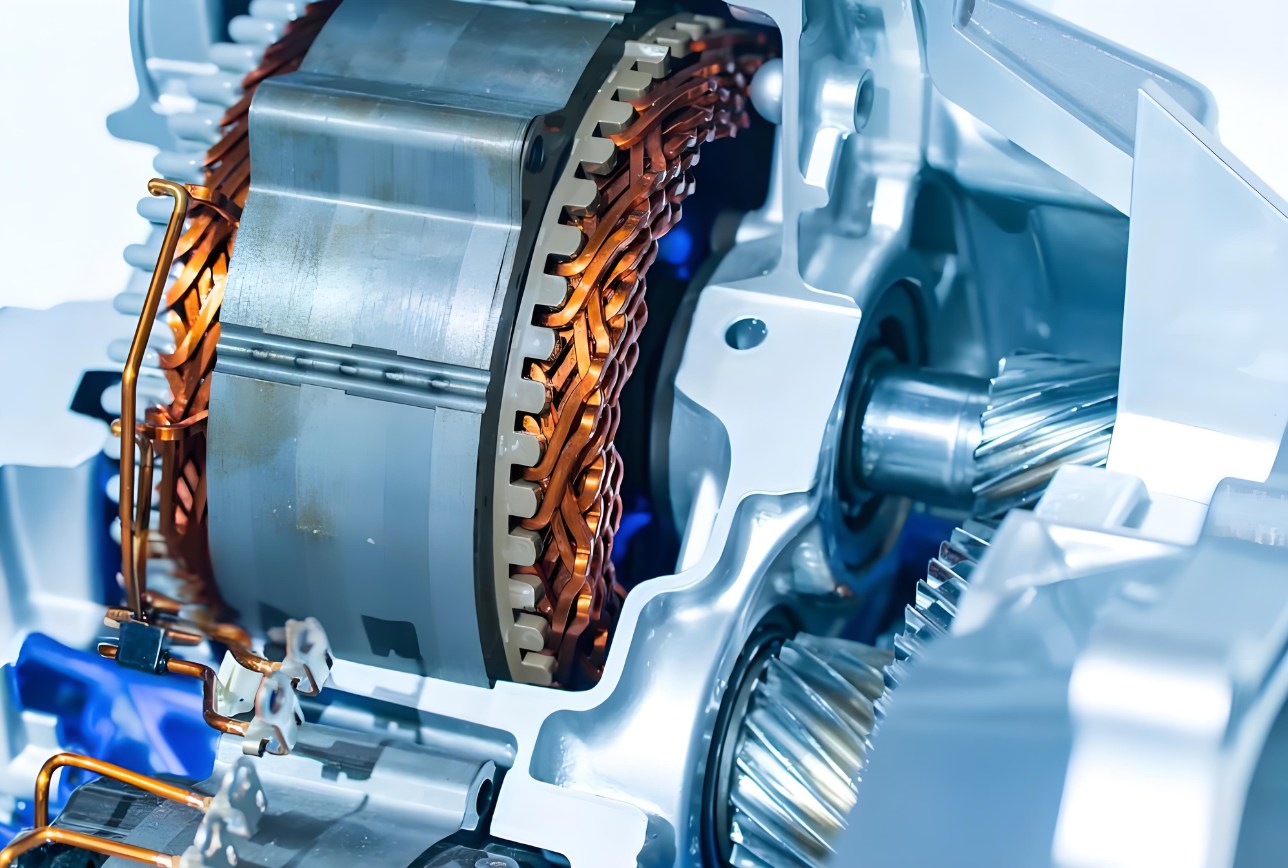

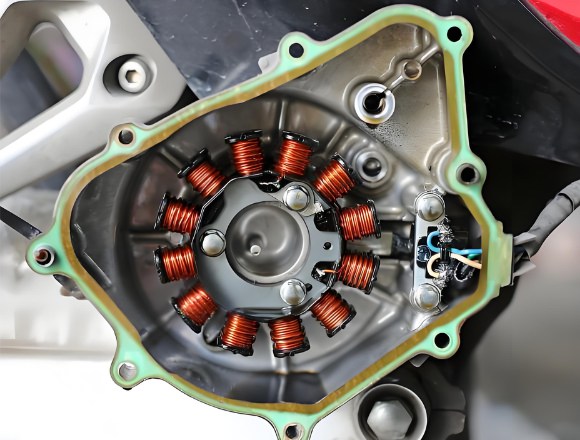

When talking about electric machines, the term “engine lamination stacks” means the carefully designed stator and rotor core laminations. These parts are the heart of any electric motor or generator. They act as the magnetic path that helps efficiently change electrical energy into movement, and the other way around. Their design and how they are made is very important for reducing wasted energy, handling heat, and making sure the final electric machine works well and lasts a long time.

Less energy wasted as heat means more of your input power gets converted into useful work – whether that’s spinning a driveshaft, compressing a fluid, or transforming voltage. This isn’t just an abstract concept; it translates directly to lower electricity bills for the end-user, longer battery life in an EV, or a more environmentally friendly footprint.

At Sino, we source premium grades of this material for our Engine Laminations. Adding a small percentage of silicon (typically 1-4%) to iron does a couple of brilliant things:

It significantly increases the steel’s electrical resistivity. This gives eddy currents another kick in the pants, making it even harder for them to flow.

Crucially, it reduces that magnetic friction, shrinking the area of the hysteresis loop. Less friction, less wasted energy.

Sino Knows the Drill: Not all electrical steel is the same, and not all scenarios need the same type.

1

This stuff is special. Its magnetic properties are optimized in one direction (the “rolling direction” during manufacturing). This makes it perfect for transformer cores where the magnetic flux primarily follows a well-defined path. Sino can provide GOES laminations for power and distribution transformers, ensuring maximum efficiency where it’s needed most.

2

This steel has good magnetic properties in all directions in the plane of the sheet. This makes it the workhorse for rotating machines like electric motors and generators, where the magnetic flux direction is constantly changing. The vast majority of Sino’s Engine Laminations for motor scenarios utilize various grades of NOES, carefully selected for the specific torque, speed, and efficiency targets of your design.

The beauty of Engine Laminations is that their impact is felt across an astonishing array of scenarios. You’ve probably benefited from them multiple times today without even knowing it!

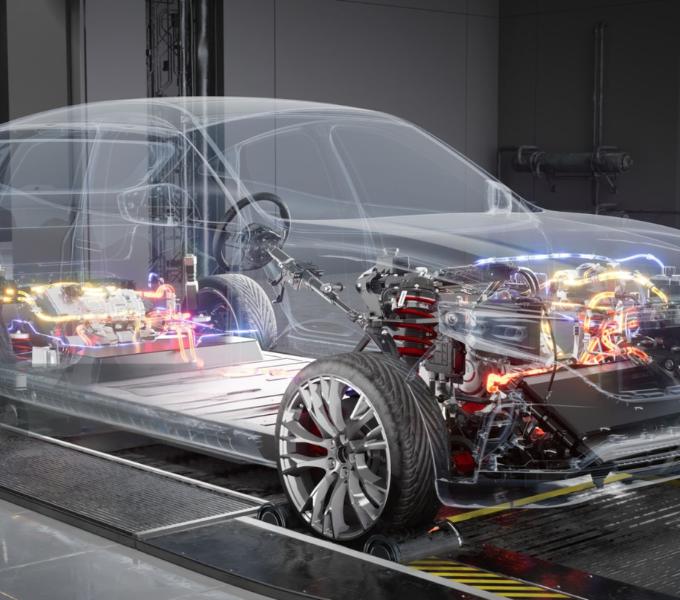

This is a big one. Every single kilometer of range in an EV, every surge of acceleration, is intimately tied to the efficiency of its electric motor(s). Sino’s Engine Laminations are helping EV manufacturers push the boundaries. Thinner gauge, high-performance electrical steels, and precision stacking allow for motors that are:

Factories, processing plants, and manufacturing facilities rely on countless electric motors running pumps, fans, conveyors, machine tools, and more – often 24/7. Efficiency here isn’t just nice; it’s a major operational cost.

From the massive generators in power plants to the transformers stepping voltage up and down across the grid, laminations are essential.

That quiet hum from your new refrigerator? The powerful yet energy-saving cycle of your washing machine or dishwasher? Thank efficient motors, and by extension, quality Engine Laminations.

In aircraft, drones, and other specialized equipment, performance, weight, and reliability are absolutely non-negotiable.

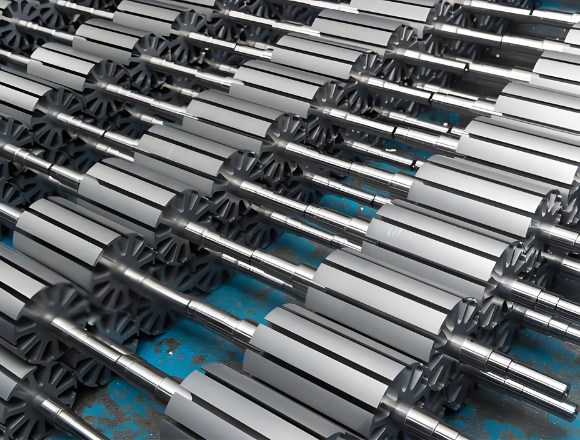

The precision and quality of lamination stacks are basically decided by the manufacturing methods used. At Sino, we use the newest and best techniques and modern factory ideas to ensure very high product quality, make a lot of products quickly, and keep costs down.

This is the most common way to make large amounts of laminations. We use high-speed stamping machines that can make over 1,200 lamination sheets per minute, with measurements as precise as ±10 μm. Our stamping tools combine cutting, locking, and stacking into one step, which greatly cuts down on extra work and speeds up the whole process. This technology is very important for supplying the fast-growing EV market.

For making early models, small amounts of products, or very complicated shapes, we use fiber and ultrafast laser systems. Laser cutting reduces rough edges and heat damage, which keeps the magnetic quality of the material. While it’s slower than stamping (usually less than 100 sheets/min), it offers unmatched freedom and precision for testing new designs quickly and for special uses.

After stamping or cutting, laminations go through a very important heating process (usually at 700–800°C in H2/N2 gas). This heat treatment is needed to bring back the material’s ability to be magnetized, which can be weakened by physical pressure during manufacturing, and to reduce wasted energy. Sino uses improved, focused heating methods with in-process checks to make sure the magnetic performance is the best it can be, while also reducing process time and energy use.

Putting the individual laminations together into a solid stack is key for physical strength and magnetic performance. Sino offers several advanced ways to assemble them:

Interlocking (Clinching/Mechanical Tabs): Commonly used for high-speed assembly, this method physically joins laminations without separate screws or glues. It’s very efficient and saves money.

Self-Bonding Technologies (Backlack): Laminations are coated with a glue that is activated by heat. They are then stacked and hardened with heat and pressure. This provides both electrical separation and strong physical structure, and it works with automatic stacking machines.

Laser and Resistance Welding: Used for very strong structures, especially in motors that move vehicles. These methods create strong physical bonds with very little bending, but they need careful control to avoid weakening the magnetic quality at the weld spot. Laser welding, in particular, can achieve stacking factors above 98%, making it easier for heat to escape.

Adhesive Bonding: Advanced glues are designed to provide both a physical bond and to reduce shaking, which greatly cuts down on sound and vibration (NVH) in EV motors. UV-light and heat-activated glues allow for quick hardening during the production process.

Making sure of the quality is very important at Sino. We use built-in cameras and eddy current sensors to check the lamination shape, rough edges, and stack height as they are being made. We are also looking into new methods like inline Barkhausen noise analysis and magnetic flux mapping to find very small problems in the material and ensure magnetic performance. These very strict quality checks make sure that every lamination stack we make meets the highest standards.

From sourcing the finest electrical steels to precision stamping/laser-cutting, meticulous insulation, and robust stacking techniques, quality is ingrained in everything we do. Our ISO-certified processes and rigorous quality control ensure you get laminations that perform as expected, every time.

We don’t just make parts; we understand the science behind them. Our engineering team can work with you to optimize lamination design for your specific scenario, helping you select the right material, thickness, and geometry to achieve your performance targets. Got a tricky magnetic challenge? Let’s talk.

Off-the-shelf doesn’t always cut it. Sino excels at producing custom Engine Laminations tailored to your unique motor or transformer design. Whether it’s a specific shape, a unique interlocking pattern, or a novel material, we have the flexibility and capability to deliver.

What’s the payoff for you when you choose Sino’s Engine Laminations? It’s all about unlocking peak performance and robust efficiency.

Heat is the enemy of insulation. Cooler cores mean the insulating materials in your motor windings last much longer, improving reliability and reducing premature failures.

If your motor isn't battling excessive internal heat, you can often get more power out of a smaller, lighter package. This is critical in scenarios like electric vehicles, power tools, or aerospace where space and weight are at a premium.

We maintain incredibly tight dimensional tolerances on our stamping and laser-cutting processes. This ensures a good "stacking factor" – meaning more iron and less air gap in your core, leading to better magnetic performance.

Tiny metal burrs on the edges of laminations can pierce the insulation, creating short circuits between sheets and negating the benefits of lamination. Sino employs advanced deburring techniques and stringent quality control to keep burrs to an absolute minimum.

The quality and consistent application of the insulating varnish or oxide layer are paramount. We monitor this closely because a compromised insulation layer is a direct path to increased eddy current losses.

Whether your design calls for interlocking ("interlocked cores"), welding, bonding, or even cleating, Sino has the expertise and equipment to produce robust, precisely aligned lamination stacks tailored to your assembly processes.

Let’s look at how these factors translate into real numbers (conceptual values for illustration):

Feature | Old-School Solid Core Approach | Sino Precision Laminated Core | The Sino Advantage |

Eddy Current Loss | Cripplingly High | Drastically Minimized | Smart design, superior insulation |

Hysteresis Loss | Moderate to High (basic iron) | Very Low (optimized silicon steel) | Premium material selection |

Operating Temperature | Often Toasty to “Ouch, Don’t Touch!” | Comfortably Cool to Warm | Significantly less internal heat generation |

Overall Efficiency | Could be as low as 50-70% | Often 90%+ (depending on motor type) | More output power for your input energy |

Motor Lifespan | Shorter (heat degradation) | Longer, More Reliable | Reduced thermal stress on all components |

Power-to-Weight Ratio | Lower | Higher | Get more punch from a smaller package |

We believe in building long-term relationships. We’ll work collaboratively with your design team, provide technical support, and strive to be a responsive and reliable part of your supply chain. Your success is our success.

At Sino, we’re proud to be master craftsmen of these Engine Laminations. We combine material science, precision engineering, and a passion for performance to deliver Engine Laminations that help you build better, more efficient products for a smarter, more electrified world.

Ready to give your next project a core advantage? Let’s discuss how Sino’s Engine Laminations can power your innovation. Get in touch with us today – we’re excited to hear about what you’re building!

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.