Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

If you’ve ever seen “farad core” and wondered what on earth it means, you’re not alone. The phrase mashes up two different ideas from power electronics:

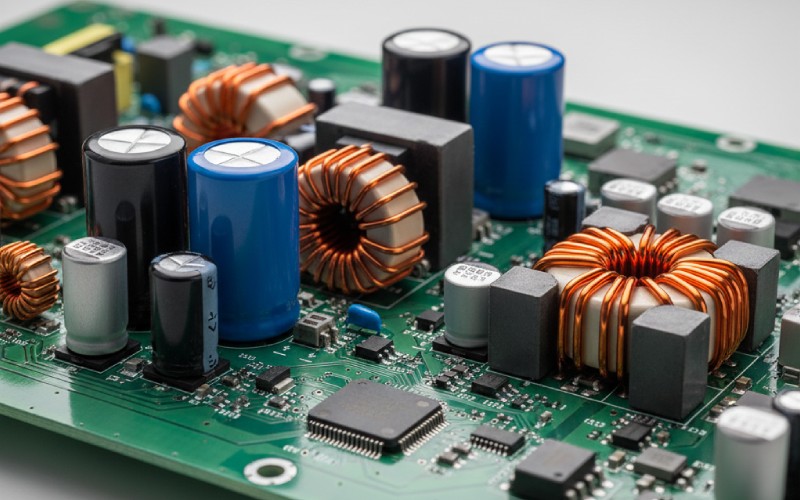

Understanding how farads (capacitors) and cores (magnetics) work together is the real unlock—whether you’re tuning audio gear, building a DC/DC converter, or squeezing life from a tiny battery pack. Below, we untangle the terminology, ground it in solid references, then go beyond the basics with practical design notes you can use today.

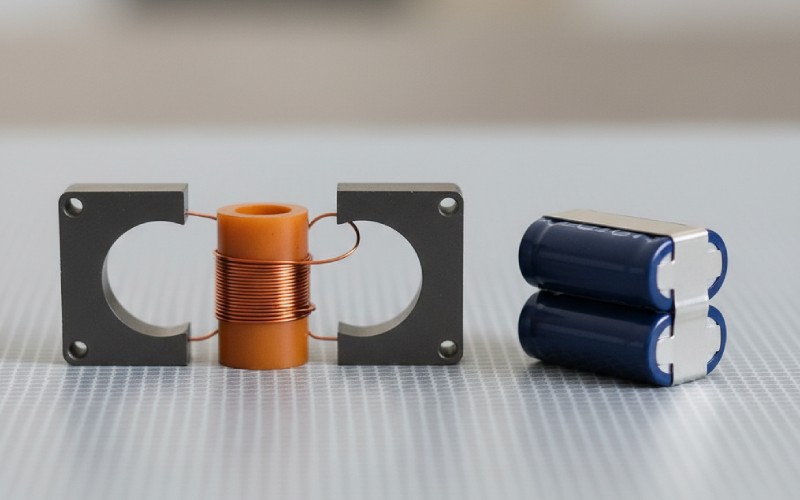

When someone says “farad core,” they usually mean either: (1) a large-value capacitor (measured in farads), or (2) a ferrite core used in inductors/transformers. They’re complementary parts of the same power path, but they’re not the same thing. Think of capacitors as your energy buffer and magnetic cores as your energy shuttle.

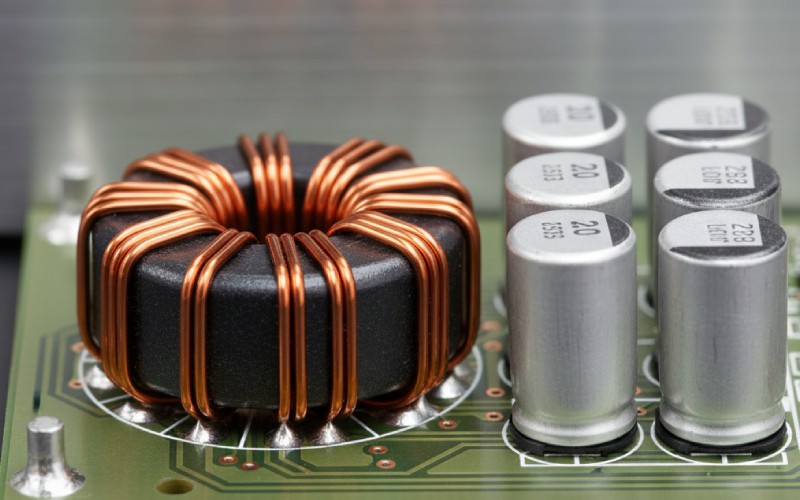

In a buck converter, an inductor wound on a ferrite core shuttles energy between the input and output, while capacitors (measured in farads) smooth the ripples and act as reservoirs. The “farad-core stack” is what gives you clean, stable rails from noisy or intermittent sources.

Modern supercapacitors are commonly rated around 2.5–2.7 V per cell, with very low ESR for fast bursts. Example parts include 100 F at 2.7 V and 630 F at 2.5 V devices—great for short-term energy buffering, peak-shaving, or brownout protection, but not energy-dense like batteries. Their sweet spot: seconds to minutes, not hours.

A ferrite core provides high magnetic permeability with low conductivity, which cuts eddy currents and keeps losses down at switching frequencies. Material choice (and geometry) determines saturation flux density, core loss, and EMI behavior. Vendors like TDK publish families optimized for power vs. signal applications, making material selection a first-order design decision.

Use this to explain your choices to colleagues, or sanity-check your BOM.

| Dimension | Capacitors (measured in F) | Ferrite Cores (inside inductors/transformers) |

|---|---|---|

| Primary role | Store/smooth energy, reduce voltage ripple | Transfer/shape energy, limit ripple current, isolate |

| Governing physics | (Q = C \cdot V), (E = \tfrac12 C V^2) | Faraday’s law, (V = L \frac{di}{dt}); B-H curve & core losses |

| Typical single-cell limits | ~2.5–2.7 V for supercaps | Saturation flux density sets current limit |

| Key performance lever | ESR (loss/heat), capacitance, leakage | Permeability, core loss vs. frequency, saturation |

| Representative parts | 100 [email protected] V, 630 [email protected] V examples on the market | PEL/PC materials for power ferrites (vendor families) |

| Lifetime drivers | Temperature, voltage derating, ripple current | Temperature rise from copper & core loss, flux swing |

| Datasheet gotchas | ±30% tolerance is common on big supercaps | Loss curves vs. frequency & flux density are essential |

| Where to start | Capacitance from ripple & transient spec | Inductance from ripple target; then check core loss |

Browsing current listings shows hundreds-of-farads supercaps at low voltages (e.g., 630 F / 2.5 V can-style parts) and 2.7 V / 100 F options with explicit ESR and lifetime specs. On the magnetics side, vendors emphasize material selection (core losses vs. frequency) just as much as geometry, underscoring that “the core is the part.” These are the constraints that shape every serious power design.

You may also see “ferrite cores” on cables (snap-on beads) to choke high-frequency noise, and even “Farad” used as a brand or token name online (e.g., FRD). These are unrelated to the physics we’ve covered here—don’t let SEO confuse your design decisions.

There isn’t a single thing called a “farad core.” There are farads (capacitors) and cores (magnetics)—and modern electronics demand that you get both right. Treat them as a pair: caps buffer, cores shape. If you size, derate, and thermally manage them together, your power rails will be calmer, your EMI will be kinder, and your products will feel… effortless.