Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

In my years in the electrical steel industry, I’ve seen how picking the right material can make or break a project. The key difference between grain-oriented and non-grain-oriented electrical steel is basic, yet it’s often confusing. This article is my attempt to clear things up and give you a simple, hands-on explanation of these two special materials. We’ll look at their special features, how they’re made, and where they work best. By the end, you’ll feel sure about picking the perfect electrical steel for your job, making sure you get the best performance and efficiency.

In my experience, the biggest difference between grain-oriented (GO) and non-grain-oriented (NGO) electrical steel is in how they are built on the inside, and that affects how they act with magnets. Think of it like this: grain-oriented electrical steel has a very orderly grain structure, with the tiny crystals lined up in one direction. This alignment, made through a special manufacturing process, creates an easy path for magnetic energy to follow. As a result, grain-oriented electrical steel shows excellent magnetic abilities, but only in that one direction. It’s like having a superhighway for magnetism; the traffic flows very well, but only in the marked lanes.

On the other hand, non-grain-oriented electrical steel, often called NGO, has a random grain pattern. This means its magnetic abilities are the same in all directions on the flat sheet. To use our road example again, NGO steel is like a good city grid, where traffic can move well in any direction, but maybe not as fast as on the superhighway. This uniform quality is a key benefit in uses where the magnetic field changes direction all the time. The main difference, then, isn’t just a small detail; it decides the best uses for each material, which is a very important point for any engineer or designer.

This clear difference in grain structure directly affects how well they work in electrical uses. The strong one-direction quality of grain-oriented electrical steel makes it the perfect material for power transformers and distribution transformers, where the magnetic energy has a steady and known path. In contrast, the same magnetic abilities in all directions of non-grain oriented electrical steel make it the best choice for machines with spinning parts like electric motors and generators, where the magnetic field is always turning. Picking the right one is key to getting the efficiency and performance you want in these tough jobs.

Having been part of making both types of electrical steel, I can tell you the manufacturing for grain-oriented electrical steel is much more complicated and exact than for non-grain-oriented steel. Making GOES involves a set of carefully managed steps, including hot rolling, annealing, cold rolling, and a final heating at a high temperature. This detailed process is designed to help a special crystal structure grow, known as the Goss texture, which gives the material its amazing magnetic abilities in the rolling direction. This process for GOES is all about creating that magnetic “superhighway” I talked about before.

The production process for NGOES, while still needing careful control, is simpler. It usually involves melting steel, forming it into slabs, and then hot and cold rolling it to the final thickness. A heating step called annealing is also part of the process to release built-up stress and improve the grain structure, but the aim is to make a random pattern of the grains. This results in the same magnetic abilities in all directions. The simpler manufacturing for NGOES is one reason it is usually cheaper than the grain-oriented type.

The last heating step is very important for both types but has different goals. For GOES, a high-temperature anneal is needed for a process where the right grain pattern forms. This process needs very exact air and heat conditions. For NGOES, the final anneal is done at a lower temperature to get a new structure with a certain grain size, which is a key factor in its magnetic abilities. Understanding these production differences helps you understand why these two steel products have such different features and prices.

I’ve always found the part that silicon plays in electrical steel to be interesting. Basically, all electrical steel is a type of silicon steel. Adding silicon to iron, usually in amounts from 0.5% to 4.8%, is what gives the material its special magnetic abilities. The main reason for adding silicon is to make it harder for electricity to flow through the steel. This is important because it cuts down on eddy currents, which are unwanted electrical flows created in the core of a transformer or motor by a changing magnetic field. By reducing these currents, we greatly lower energy loss as heat, which leads to better efficiency.

The amount of silicon also plays a big part in improving the material’s magnetic permeability, which is its ability to help a magnetic field to form within it. High magnetic permeability lets the magnetic energy be focused and led well through the core of an electrical device, which is needed for it to work correctly. Also, adding silicon helps lower what is called hysteresis loss, another type of energy loss that happens as the magnetic field changes direction over and over. So, really, silicon is the magic ingredient that changes regular steel into a high-performance material for many electrical uses.

It’s important to know that the amount of silicon added is a careful balance. More silicon makes the magnetic abilities better and lowers core losses, but it also makes the steel harder and more likely to break. This can make manufacturing harder, especially during rolling. This is why you see different grades of silicon steel with different amounts of silicon, each made for certain uses. For example, non-grain oriented steels usually have about 2% to 3.5% silicon, while grain-oriented steels often have more, around 3% to 4.5%, to get the best performance in transformers.

From my view as someone who works a lot with electrical steel, understanding core loss is very important when designing or checking an electric motor. In simple terms, core loss, also called iron loss, is the energy that is lost as heat inside the motor’s core when it’s running. This loss is a normal result of the changing magnetic field that is needed for the motor to work. Lowering this loss is a main goal in motor design because it directly leads to better efficiency, lower running temperatures, and in the end, a motor you can count on that saves money.

There are two main parts to core loss: hysteresis loss and eddy current loss. Hysteresis loss happens because of the energy needed to magnetize and demagnetize the core material with each cycle of the changing current. You can think of it as a kind of magnetic friction. The features of the silicon steel, like its grain structure and what it’s made of, is a big factor in how much loss there is. Eddy current losses, on the other hand, are caused by small, looping currents created inside the core material by the changing magnetic field. These are the losses that adding silicon to the steel is so good at reducing.

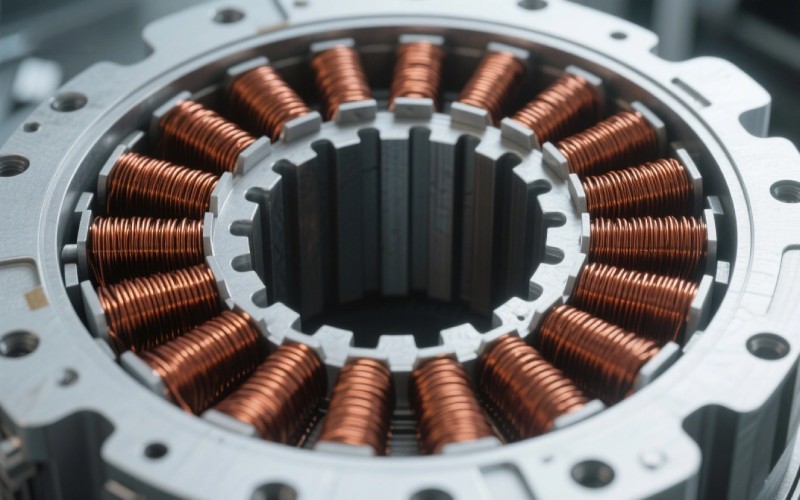

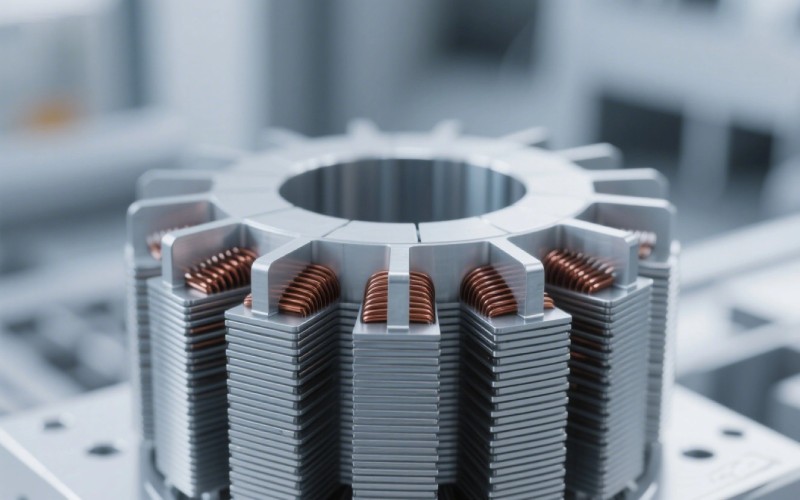

To fight eddy current losses even more, the cores of electric motors are not made from a solid piece of steel. Instead, they are built from thin sheets, or layers, of electrical steel that are stacked together. Each sheet is covered with a material that stops electricity to prevent eddy currents from flowing between them. This is why you’ll often hear electrical steel called lamination steel. The thickness of these sheets and the quality of the covering are both key things for cutting down core loss. Picking the right grade of non-grain oriented electrical steel, with its low core loss features, is therefore a basic step in designing a high-efficiency electric motor.

When I’m asked to name the main differences in magnetic properties between grain-oriented and non-grain-oriented electrical steel, I always go back to the ideas of being directional or uniform. Grain-oriented electrical steel is anisotropic, which means its magnetic abilities are strong in one direction. It has extremely high magnetic permeability and very low core loss in the direction of the grain pattern, which is the rolling direction during manufacturing. However, it doesn’t work nearly as well in other directions. This makes it a special material, perfect for uses where the magnetic energy follows a steady, straight path.

In contrast, non-grain-oriented electrical steel is isotropic, which means it has the same magnetic abilities in all directions on the flat sheet. While its best magnetic performance in one direction doesn’t match GOES in its best direction, this consistency in all directions is its main strength. This uniform performance is needed for uses where the magnetic energy is spinning, as it is in electric motors and generators. The choice between these two materials, then, depends on knowing how the magnetic field works in your specific use.

To put some numbers on it, the magnetic permeability of grain-oriented steel in its best direction can be many times higher than that of non-grain-oriented steel. This lets us design smaller and more efficient transformers. On the other hand, if you used GOES in a machine with a spinning magnetic field, you would have much higher core losses and worse performance compared to using NGOES. The magnetic flux density, or the strength of the magnetic field the material can take, is another important ability where GOES usually has an advantage in its specific direction.

Practically speaking, telling the difference between grain-oriented and non-grain-oriented electrical steel is hard to do just by looking, as they are both thin steel sheets. But, there are a few key signs and tests I’ve used. The surest way to tell them apart is to check the spec sheet from the maker. These data sheets will clearly say the grade of the steel and if it is grain-oriented (often labeled as GO or CRGO for cold-rolled grain-oriented) or non-grain-oriented (NGO or CRNGO).

If you can’t get the specifications, a more practical test is to watch how they act with magnets. A simple test I’ve used involves a small compass. If you put a compass near a sheet of grain-oriented steel, you’ll see a much stronger magnetic pull along the rolling direction than the sideways direction. This is a direct result of its one-directional magnetic abilities. With non-grain-oriented steel, the pull will be mostly the same no matter how you turn the sheet near the compass.

Another, more technical way involves measuring the material’s magnetic abilities, like its permeability or core loss, in different directions. This, of course, needs special tools. By looking, the surface coating can sometimes give a hint. Grain-oriented electrical steel often has a certain type of coating, like a forsterite (magnesium silicate) base coat, which is part of the process to get its magnetic abilities. But, this is not a perfect method as coatings can be different. In the end, for any important use, using the maker’s paperwork is the safest way to be sure you are using the right material.

In my experience, for most electric motors, non-grain-oriented electrical steel is the clear choice. The reason for this comes back to the main difference in their magnetic abilities. Electric motors use a spinning magnetic field to create turning force and movement. This means the direction of the magnetic energy inside the motor’s core is always changing. Non-grain-oriented steel, with its same magnetic abilities in all directions, is perfect for this changing situation. It gives steady performance no matter the direction of the magnetic field, which is needed for the motor to run smoothly and well.

Using grain-oriented steel in a standard electric motor would usually be a bad choice. While it has better magnetic abilities in one direction, it doesn’t work nearly as well in other directions. In a spinning magnetic field, this would cause uneven work, more shaking, and much higher core losses as the magnetic field moves away from the steel’s preferred grain direction. This would end up making a motor that’s less efficient and that you can’t count on as much. The steady, all-around performance of NGO steel is what makes it the industry standard for motor uses.

However, there might be some very special or unusual motor designs where the magnetic energy path is mostly in one direction. In such rare cases, it’s possible a designer might think about using grain-oriented steel. But, for the great majority of standard AC and DC electric motors, from small home appliances to big factory machines, non-grain-oriented electrical steel is the right and best material to use. Picking the right grade of NGO steel, with the thickness and core loss features you want, will have a big effect on the final performance and efficiency of the motor.

From what I’ve seen in the market over the years, there is a clear and steady price difference between grain-oriented and non-grain-oriented electrical steel. As a general rule, grain-oriented electrical steel is the more expensive of the two. This higher price is a direct result of its more complicated and energy-heavy manufacturing process. As I’ve said, getting the exact grain pattern needed for GOES involves more carefully controlled steps, which adds to the total manufacturing cost.

The extra cost for grain-oriented steel can change depending on market demand, the cost of raw materials, and the specific grade of the steel. However, it’s pretty common for GOES to be a lot more expensive than NGOES. For example, in early 2024, the extra cost for magnetic steel over non-magnetic cold-rolled steel was over 70%, with NGO prices being historically high, affected by the market for GO steel. This shows that while NGO is usually the cheaper option, market changes can lead to big price differences.

While the first cost of non-grain-oriented steel is lower, it’s important to think about the total cost over time for your project. For a power transformer, the higher first cost of grain-oriented steel is often worth it because of its better efficiency and lower core losses over the transformer’s lifespan. The energy savings can be very large, making it a cheaper choice over time. For most motor uses, the performance benefits of non-grain-oriented steel, along with its lower price, make it the more practical and money-saving solution.

In my work, the search to lower core loss is always ongoing, and the choice of electrical steel is a key part of this work. Picking the right type and grade of steel is one of the best ways to lower energy waste in transformers and motors. For transformers, using grain-oriented electrical steel is extremely important for reducing core loss. Its unique grain structure gives an easy path for the magnetic energy, which greatly lowers hysteresis losses. Also, the high silicon amount and thin sheets of GOES help to stop eddy currents. The result is a transformer that works with much better efficiency, saving energy and lowering running costs over its life. Using advanced grades of CRGO can reduce core losses by as much as 74% compared to older, standard grades.

For electric motors and other machines with spinning parts, the key to reducing core loss is picking the right grade of non-grain-oriented electrical steel. Since the magnetic field is always changing direction, the same magnetic abilities of NGO steel are needed to lower both hysteresis and eddy current losses. Thinner sheets of NGO steel with lower stated core loss values will naturally make a more efficient motor. Makers offer a wide range of NGO grades, letting designers find the right balance between performance and cost for their specific job. Making the right choice here can lead to a big drop in the motor’s running temperature and a rise in its total efficiency.

The effect of picking the right steel is more than just how the device works right away. By reducing core loss, we are also helping with the bigger goal of saving energy and lowering the impact on the environment of electrical machines. Less wasted energy means less electricity has to be made. So, taking the time to understand the features of grain-oriented and non-grain-oriented electrical steel and making a smart choice is not just good engineering practice; it’s a step toward a future that can last.