Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

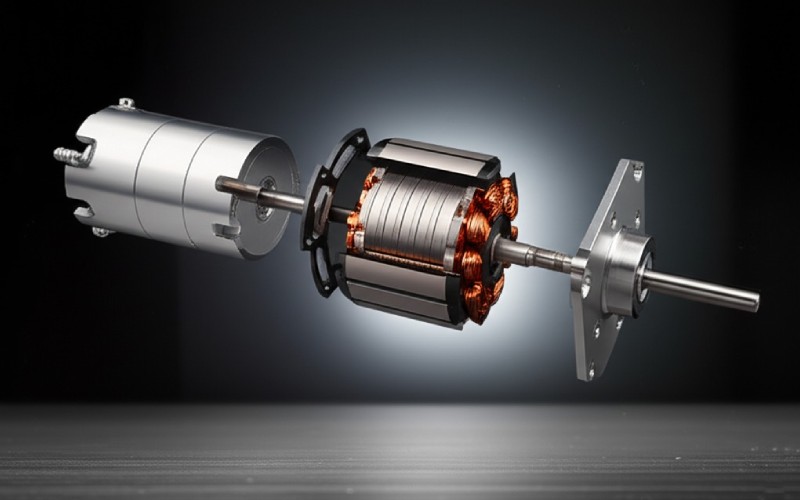

A brushless motor is something simple and neat. It is only a few main components. How these simple parts worked with each other was really cool. Learning about each motor component is the most important thing for picking the right motor for any job. This article will show you how. We will look at all the parts of a brushless motor. We will see how they make things move. You will find out why it is very helpful to know this for your next application. This is a guide for anyone who wants to really learn how a brushless motor works, from the inside.

When I was new to this, I thought a motor was just one object. You give it electricity, and it spins. But a motor is made of many parts that work with each other. The way a brushless motor works is because of the great way two main parts, the stator and the rotor, work together. A brushless DC motor, also called a BLDC motor, uses electricity to make a magnetic field. This field then pushes and pulls on magnets that are on the rotor.

This easy push-and-pull is what makes the center part of the motor spin. It is not like older types of motors, so there are no brushes that can get worn out. This makes the brushless motor very dependable and it works very well. The main idea is getting the right amount of electricity at the right time. This creates a magnetic field that spins. This spinning field makes the rotor spin along with it. This simple idea is used in many things we see every day. Every motor component has a task to do to make this rotation happen in a smooth way. A good motor will do this task very well.

The electricity turns into magnetic power, and then it turns into movement. This way of working does not waste much power. That means less energy is lost as heat. This is a very big reason why the brushless motor is used so much. What is great about this motor is that it is simple and works really well. A motor that is designed well gives you a lot of output even though it is small. To learn all about systems that use a motor, you first have to understand this main idea. Everything starts with that spinning magnetic field inside the motor.

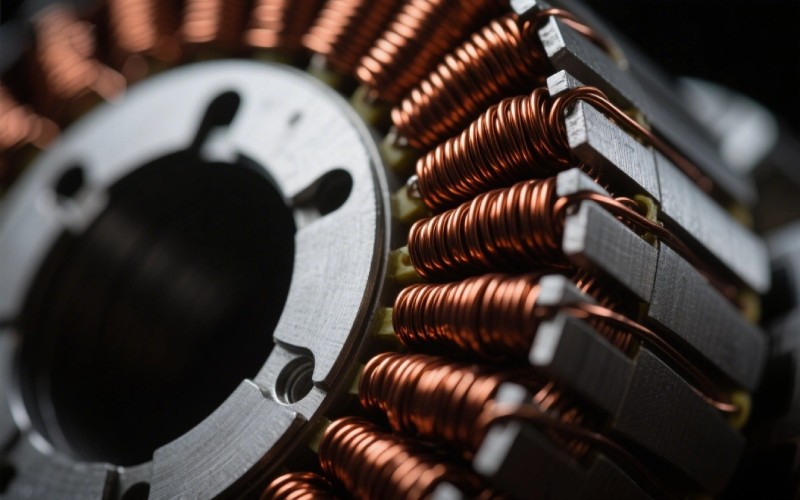

So, just what is a stator? The name itself gives you a hint: it stays in one place. The stator is the part of the motor that does not move. It is a main motor component made from coils of wire. When electricity goes through these wire coils, the stator becomes a strong magnet that uses electricity. It can make a strong magnetic field. The stator does not move at all. Its job is to make the moving magnetic field that makes the motor go.

You can think of the stator as being like the body of an engine. It holds all the parts in place and does the hard work. The coils on the stator are put into groups. A controller sends power to these groups, one after the other. This is the thing that makes the magnetic field spin. How many groups, or poles, are on the stator helps control the motor’s speed and turning force. A motor with more poles will often have a stronger torque but will not spin as fast.

The way the stator is designed is very important for how well the motor will work. The way the wires are wrapped and the type of material in the middle can change the motor’s power and how well it uses energy. A good stator design is a very important element for any motor that needs to work well. The stator is like the heart of the motor. It makes the power that causes everything else to move. This motor part is really needed.

If the stator is the part that stays still, then the rotor is the part that spins. The rotor in a brushless motor has a very important element on it: a group of strong magnets. These are known as rotor magnets. These magnets are permanent magnets. This means they have their own magnetic field that does not go away, with a north and south pole. They are the other important part of the motor. The rotor is the spinning component of the motor.

The stator makes a spinning magnetic field. The permanent magnets on the rotor are pulled and pushed by this field. You can picture holding one magnet and then using another magnet to make it spin without ever touching it. That is just what is happening inside a brushless motor. The rotor magnets want to line up with the magnetic field from the stator. As the stator’s field spins, it pulls the rotor magnets with it. This makes a smooth spin and a strong torque.

How strong each magnet is and where it is placed on the rotor is very important. Good magnets make a stronger magnetic pull. This makes a motor with more torque and one that works better. The rotor magnets are a key component that has a direct effect on the motor’s power output. This simple push and pull between the stator’s field and the rotor’s magnet is what makes this kind of motor work so well. A strong magnetic link means you have a strong motor.

A brushless motor needs something to control it. It has to know where the rotor is all the time. This is why a feedback system is needed. The motor controller needs to know the exact position of the rotor magnets. This helps it send power to the correct coils in the stator just at the right moment. If it did not have this information, the motor would not spin the right way. It might move in a shaky way or not spin. The feedback system is like the motor’s eyes and ears.

This feedback system always sends information about the position back to the controller. The controller then uses this information to change the electricity sent to the stator. This is how it makes the smooth, spinning magnetic field that pulls the rotor. A good feedback loop is very important for controlling the motor in an exact way. This is very true for jobs that need the speed or position to be just right. The feedback element is a very important motor component.

There are a few kinds of feedback parts. Each kind is good for different things. The kind of feedback system you pick will depend on the job you need to do. Some jobs need very exact position information. Other jobs might just need simple information about the speed. The right feedback system will make sure the motor works at its very best. A motor that does not have feedback is like trying to fly with your eyes closed. The feedback gives the motor control. This feedback is very important.

So what is an encoder? An encoder is a kind of feedback part. It is a very common element that is used with a brushless motor. Its job is to let the controller know the exact position and speed of the motor shaft. I use an encoder a lot in my work because it gives very exact feedback. An encoder gives a lot more information than simpler sensors do.

An encoder works by making a set of electrical signals as the motor spins. It could be a magnetic encoder or one that uses light. An optical encoder has a little disk with lines on it. A light is shined through the disk. As the motor turns, the lines block the light, and this makes signals. A magnetic encoder has a special magnet and sensors that do a similar thing. The controller counts these signals to find out the exact position of the rotor. If an encoder can make more signals in one spin, the position feedback is more exact.

This exact information makes an encoder the perfect choice for many tasks. Robots, special cutting machines, and printers all have to know the exact position of a motor. An encoder gives them this very important feedback. Using an encoder can make a system work much better. It lets you control speed and position in a very exact way. The information from the encoder helps the motor to run in a smooth way and use less power. An encoder is a great element for any job that needs to control movement. The encoder is a wonderful motor part.

We have learned that a brushless motor needs feedback. But how does it get this information about its position? Other than an encoder that gives a lot of detail, many BLDC motor designs use a simpler part. They use Hall effect sensors. These are small and simple sensors that can feel a magnetic field. They are usually put inside the motor, close to the rotor magnets. This is a very common and low-cost way to get position feedback.

As the rotor turns, its magnets go past the Hall effect sensors. Each magnet has a north and south pole. The sensor can tell which pole is going by and it sends a signal to the controller. Most motors have three Hall sensors. The pattern of signals from these three sensors gives the controller a general idea of the rotor’s position. It divides one full spin into six parts. For many jobs, this feedback is all that is needed.

This method gives the controller the basic position information that it needs. The controller then knows which coil on the stator to give power to next. This keeps the rotor spinning in the correct direction. It is not as exact as an encoder, but this kind of feedback can be trusted and does not cost a lot of money. It is a smart way to control the motor. The system uses the magnet on the rotor to both make movement and give position feedback. Knowing the rotor position is the most important part of making a brushless motor work.

In a lot of my projects, I do not have a lot of room. I need a motor that is small. A motor and a separate encoder can use too much space. The good news is that you can buy a motor that has the feedback part already built right in. Many companies will sell a full motor package. This means the motor, the encoder, or other sensors are all put together into just one piece. This makes everything much simpler.

When you integrate the feedback element, you get a system that is smaller and can be trusted more. The encoder or sensor has already been put in place and lined up just right at the factory. This saves a lot of time when you are putting things together. You do not have to worry about trying to line up a delicate encoder on your own. A single package also means you have fewer wires and plugs. This makes the whole design look cleaner and it is less likely to have issues. This is a very good way to support a small design.

This all-in-one way is perfect for a small machine or a robot arm. I always try to find a motor that is sold as a full package. It helps make the design work simpler. The cost might be a bit more at the start. But the time and work you save usually make it a good deal. You get a motor that is ready to be used as soon as you get it. You can easily integrate it into your machine.

Here is a table that shows some common choices for feedback:

| Feedback Type | How Exact It Is | Cost | Good For |

|---|---|---|---|

| Hall Sensors | Not very exact | Low | For simple speed control (like in fans) |

| Magnetic Encoder | Pretty exact | Medium | For many uses, even in hard places |

| Optical Encoder | Very exact | High | For when the position must be perfect (robots) |

When you are looking for a motor, you will find that they are often sold in a “series.” A motor series is a group of motors that are made in a similar way, but they come in different sizes or have different amounts of power. For instance, a series might have motors that are all the same width but have different lengths. A longer motor in the same series will usually have more torque. This makes it simple to find the motor that is just right for what you need.

When I am picking a motor series, I check a few key things. First, what is the range of performance? Does the series give me a good choice of torque and speed for what I need? Second, what other choices are there? Can I buy the motor with different wire wrappings? Can I pick my own feedback element, like an encoder or Hall sensors? A good motor series should give you choices.

Last, I check the quality and help I can get from the company that makes it. Is the information sheet easy to read? Do they offer good help if I have questions? Picking a motor is a choice that you will stick with for a long time. You want to work with a company that will help you with its product. A good series of motors gives you choices. It lets you make your project bigger or smaller without having to change everything you have set up. This motor series is a very good choice.

Picking the right motor can seem difficult. There are so many choices. But if you do a few things first, you can find the perfect motor. The first thing to do is to know what your job needs. What do you need it to do? Do you need it to go very fast? Do you need a strong turning force to pick up something heavy? Do you need to control its position in a very exact way? You have to answer these questions at the start.

After you know your goals, you can look at the details about the motor. The two most important numbers are speed and torque. Be sure that the motor can give you the torque you need at the speed you plan to run it. Look at how much power it needs. Will the motor run on the voltage you have? Think about how big and heavy it is. Will the motor be able to fit in your design? A small motor is often a good choice.

In the end, think about the place where the motor will be used. Will it be in a hot or dusty place? Some motors are made to work well in hard places. You have to pick the right motor that can last. Do not just choose the motor with the most power. Choose the motor that is the best fit for the job you are doing. A little bit of planning now will save you from a lot of problems down the road. This will help you find the right motor.

When we discuss a motor’s performance, there are a few important things. The first is how well it works, or its efficiency. This tells you how well the motor uses electricity to make things move. A motor with high efficiency does not waste a lot of power by getting hot. This is very good for things that run on batteries. It also means the motor will not get as hot when it is running. Good performance begins with good efficiency.

Another key thing is the torque output. This is the turning force that the motor can make. Some jobs need a high torque at the start to get going. Other jobs need the same amount of torque all the time to keep running. A motor’s torque chart will show you how much torque it can make at different speeds. The motor’s power output is also a very important part of its performance.

Lastly, think about the motor’s dynamic response. This is how fast the motor can react to change its speed or direction. For a robot arm, you would need a motor that can react very quickly. This will depend on the way the motor is made and the controller that is used with it. All of these things—efficiency, torque, and response—work together to show the motor’s performance. A good motor will have a good mix of all three things for the job it needs to do. The right motor will help your project be a success.