Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

I’ve spent a lot of my career around machines. I’ve seen how a small, humming electric motor can be the heart of a huge operation. I’ve also seen how a poorly managed motor can waste a ton of money and cause big headaches. That’s why I want to share what I’ve learned. This guide to electric motor optimization isn’t about complicated math. It’s about simple, smart choices you can make to improve your motor performance and motor efficiency. Whether you run a small shop or a large factory, this article will show you how to get more work done with less power. You will save money and make your machines last longer.

Let’s start with the basics. An electric motor is a machine that converts electrical energy into mechanical energy. In simple terms, it takes electricity from the wall and turns it into motion. This motion can spin a fan, run a conveyor belt, or power a pump. It’s the workhorse in most industrial settings. The an electric motor converts electrical energy to motion is a key process.

Why should you care so much about motor performance? Because it directly affects your bottom line. An inefficient electric motor uses more electricity than it needs to. This means higher energy bills. Over a year, this can add up to thousands of dollars in waste. Good motor performance means you get the most work out of the power you pay for. It also means the motor is less likely to break down, saving you from costly repairs and downtime.

I’ve seen this mistake a lot. People think a bigger motor is always better. That’s not true. Choosing the right motor size is one of the first steps to optimize your system. A motor that is too big for its job will run inefficiently. It will waste energy and have a poor power factor, which your power company might penalize you for.

You need to match the motor’s horsepower to the load it needs to move. Horsepower is a measure of the motor’s power. Also, look at the torque requirement. Torque is the twisting force the motor creates. The motor’s specification sheet will give you these details. Getting this right from the start is much easier than fixing problems later. A motor that is too small will overheat and fail early. A motor that is too large wastes money upfront and every day it runs. It’s about finding the perfect fit. Your goal is to match the power output to the job’s needs.

Not all motors are the same. You will likely find two main types in your facility: single-phase and three-phase motors. A single-phase motor runs on a single source of alternating current. You find these in homes and small shops for things like fans and drills. They are simple but not as efficient as their bigger cousins.

For most industrial applications, a three-phase electric motor is the way to go. These motors run on three alternating currents that are out of step with each other. This design gives them a smoother and more constant torque. They are more efficient, reliable, and have a better power factor than single-phase motors. If you want to optimize electric motor operations, using three-phase power where possible is a smart move. They deliver a better balance of efficiency and power.

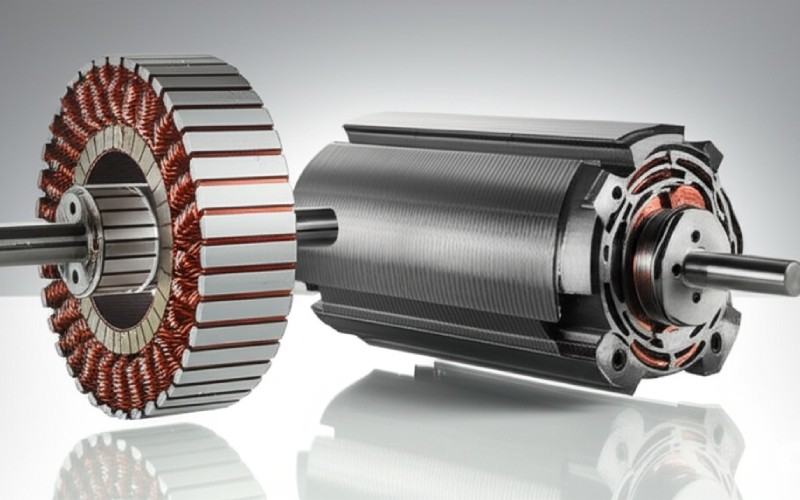

You don’t need to be an engineer, but knowing the basic motor components helps. The two main parts are the stator and rotor. The stator is the stationary part of the motor. It has a coil of wire, called the winding, that creates a magnetic field when current flows through it. The rotor is the part that spins. The magnetic field from the stator pushes and pulls on the rotor, causing it to turn and create torque.

The interaction between these two parts is what makes the electric motor work. The quality of the materials in the stator and rotor affects the motor’s power density and overall motor efficiency. The insulation around the winding is also very important. If the insulation breaks down from heat, the motor will fail. This is why a well-built electric motor with quality components is a good investment.

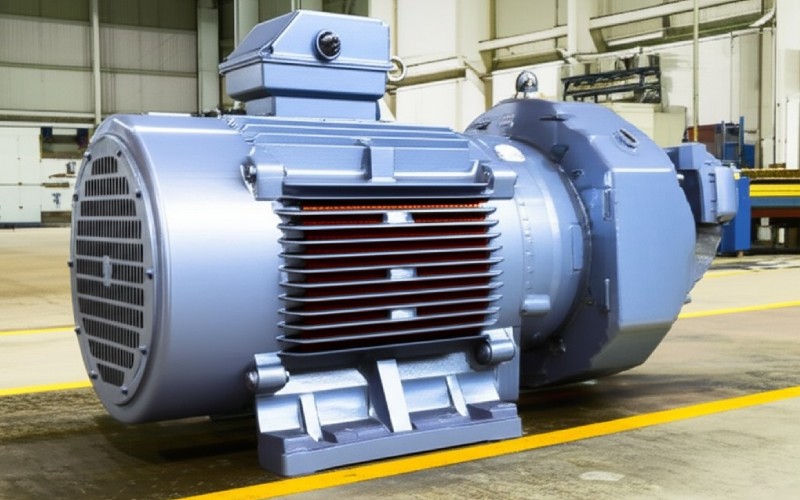

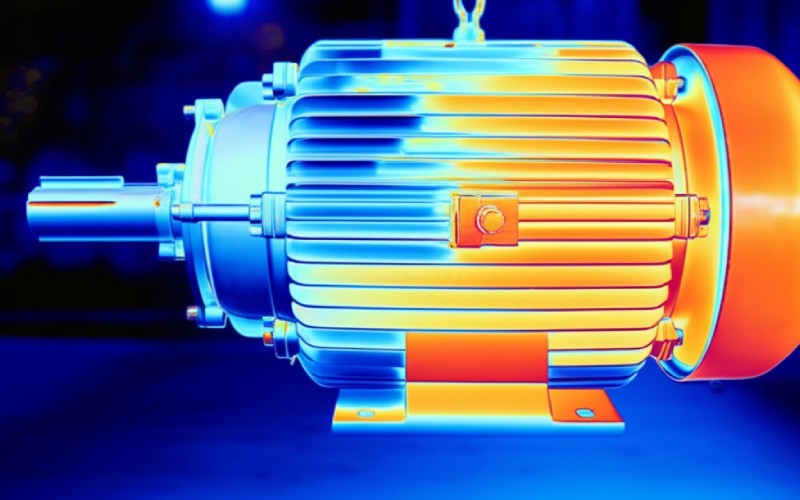

Heat is the biggest enemy of an electric motor. Every motor creates some heat. This is called heat generation. But excessive heat will destroy a motor. It damages the windings and bearings and can lead to a quick motor failure. This is why thermal management is so important. A motor that runs cool runs more efficiently and lasts longer.

Good thermal management means getting rid of that excessive heat. Many motors use a fan to blow air over the casing. This is called forced air cooling. For a high-performance motor, you might need more advanced cooling systems. Some high-tech applications, like in EVs or aerospace, use liquid cooling. The goal is to prevent overheating and keep the motor within its safe temperature range. This helps maintain optimal motor life.

When you want the best performance and efficiency, the materials inside the motor matter a lot. The choice of materials affects everything from power density to core loss. This is especially true for building a high-performance motor. For example, the core of the stator is made of thin sheets of electrical steel. This design is called a lamination.

Better materials, like advanced soft magnetic alloys, can improve performance. These soft magnetic materials are used in the motor’s core. They have high permeability, which means they can support a strong magnetic field. This leads to higher torque and better power density. Better materials also reduce eddy current losses, which is a type of energy waste. Good material selection means the motor can handle a higher magnetic flux density without saturation, leading to higher power output and better electric motor efficiency. The conductivity of the conductor in the windings is also key.

Engineers face many motor design challenges when trying to maximize performance. One of the biggest challenges is balancing size, cost, and efficiency. Everyone wants a small, cheap, and powerful motor, but these things often work against each other. Improving one area can make another worse. For example, using better materials to increase power density can make the motor more expensive.

Another challenge is managing heat. As motors get smaller and more powerful, their power density increases. This means more heat is generated in a smaller space, making thermal management harder. Engineers also work on reducing motor noise and vibration. They use advanced manufacturing processes and materials like permanent magnets to create a better electric motor. Overcoming these challenges is key to building the next generation of high-performance motors for things like EVs and consumer electronics. Improving power density is a constant goal.

You can’t improve what you don’t measure. To optimize your motors, you need to check their key performance indicators. One of the most important is the power factor. The power factor is a measure of how effectively the motor is using electricity. A power factor close to 1.0 is great. A low power factor means you are wasting energy. You can use a power quality analyzer to measure this.

You should also monitor the motor’s load factor. This tells you how hard the motor is working compared to its full-rated load. A motor that is lightly loaded (a low load factor) is inefficient. Also, check for voltage unbalance in three-phase systems. Even a small difference in voltage between the three phases can cause the motor to run hot and inefficiently. Monitoring voltage and current can give you early warnings of problems. A simple check of the temperature rise during operation is a good indicator of motor health.

Regular maintenance is a simple but powerful way to get performance improvements from your electric motor. It doesn’t have to be complicated. Start by keeping the motor clean. Dirt and dust can act like a blanket, trapping heat and causing the motor to run hotter. This can shorten its lifespan. Also, make sure the motor’s cooling vents are not blocked.

Listen to your motors. If you hear a new noise, like a grinding or whining sound, it could be a sign of a bearing problem. Check for vibration. Too much vibration can mean the motor is not aligned correctly. Proper lubrication of bearings is also key to a long motor life. These simple steps can prevent big problems, improve electric motor performance, and lead to significant efficiency improvements. You can do this with your current operating conditions.

Finally, remember that where and how a motor runs has a big impact on its performance and efficiency. The operating conditions can change how a motor performs. For example, a motor operating in a very hot room will have a harder time staying cool. A motor running at a high altitude, where the air is thinner, will also have trouble with cooling. The operating temperatures must be considered.

The quality of your electrical supply also matters. Unstable voltage can harm your motor. The load conditions are also critical. If the load changes all the time, the motor’s efficiency can suffer. When you select a motor, think about the environment where it will live. Choosing a motor designed for your specific operating conditions is a key part of motor optimization. This is how you get to peak performance. A 10 kilowatt (kw) motor in a lab is different from a 10 kilowatt (kw) motor in a dusty factory. Choosing premium efficiency motors that meet NEMA standards can help you achieve better motor efficiency and lower operating costs.

I know we’ve covered a lot of ground. But if you remember just a few things from this guide, you’ll be on the right track to increase motor efficiency.