Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

If you work with electric motors or want to understand them better, this is for you. Choosing the right steel grade for motor laminations is super important. It can make a motor run great or waste energy. In this article, This article will break down what you need to know about electrical steel. You’ll learn how to select the best lamination steel for your needs. This will help your motors run with better efficiency.

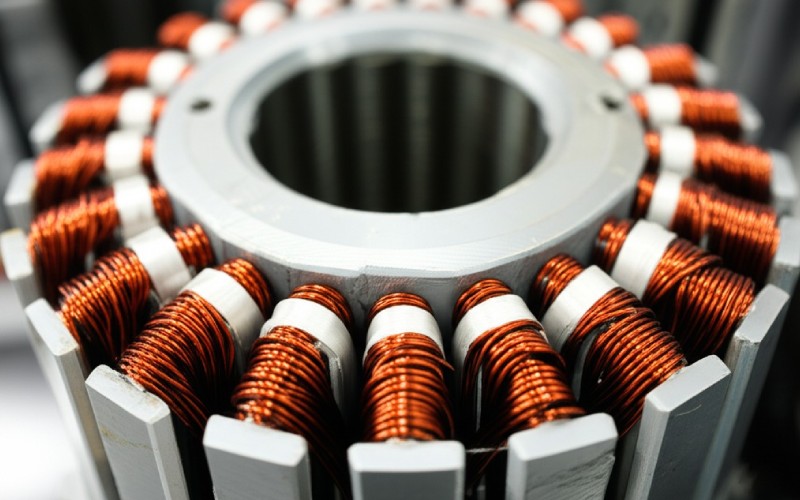

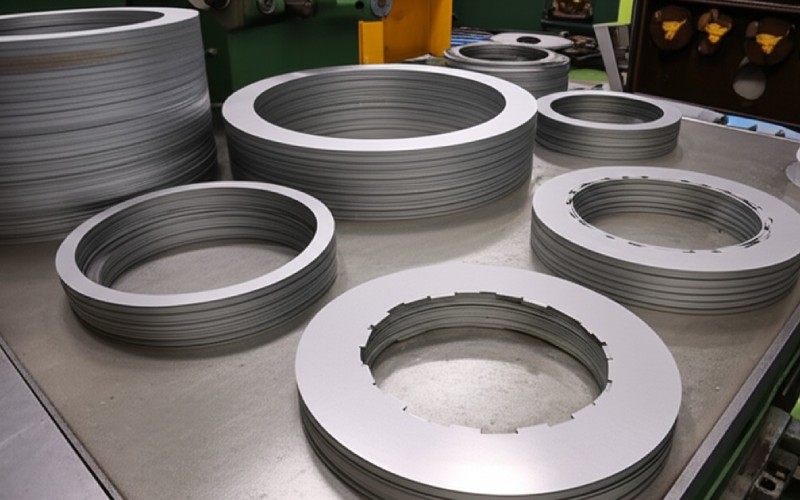

When we talk about a motor, we often think of the power it gives. But inside, there’s a special kind of steel used. This is electrical steel, also known as lamination steel or silicon steel. It’s not just any steel. It’s made to have good magnetic properties. These laminations are thin sheets of this steel. We stack many lamination sheets together to make parts of a motor, like the stator and rotor.

Think of a lamination like a thin slice of bread. You stack many slices to make a loaf. In a motor, these laminations guide the magnetic field. The grade of electrical steel tells us about its quality and how well it will perform. There are many different grades, and picking the right one is key. The steel grade affects how much energy the motor uses. A good grade of lamination steel means less wasted energy.

This electrical steel is usually an iron alloy. That means it’s mostly iron with other things added, like silicon. The way these laminations are made and their thickness are very important. We need to insulate each lamination from the next. This helps to reduce energy losses called eddy current losses. So, understanding the lamination steel grade helps us build better, more efficient motors.

Well, silicon is a key ingredient in silicon steel, which is a type of electrical steel. Adding silicon to iron changes its magnetic properties for the better. One big thing silicon does is increase the electrical resistivity of the steel. Higher resistivity is good because it helps to reduce core loss. Core loss is energy wasted as heat in the motor core. We want to keep core loss low for good efficiency.

The amount of silicon content in silicon steel can change. Usually, it’s a few percent. More silicon generally means lower core loss. But, too much silicon can make the electrical steel harder to punch or stamp into lamination shapes. So, manufacturers need to find a good balance. The silicon helps make the magnetic properties of the steel more stable over time, too.

So, when you see “silicon steel” or “electrical steel” for a motor lamination, remember that silicon is there for a reason. It helps the motor perform well by controlling the magnetic field and reducing energy waste. The silicon content is a big factor when a manufacturer decides on the steel grade to produce. This special alloy of iron and silicon is a workhorse in electric motors and generators.

Yes, grain orientation in electrical steel matters a lot! Let me explain. Steel is made of tiny crystals called grains. In some types of electrical steel, these grains are lined up in a specific direction. This is called grain-oriented electrical steel. This type of steel has excellent magnetic properties in the direction the grains are rolled. It’s often used in a transformer where the magnetic field follows a set path.

For many motors, especially those where the magnetic field has to rotate or go in many directions, we use something else. This is often non-oriented steel (or NGOES – Non-Grain Oriented Electrical Steel). In this electrical steel, the grains are not lined up in one special direction. This means its magnetic properties are more isotropic, or similar in all directions in the plane of the lamination. This is very useful for the rotor and stator parts of a motor.

So, when you select an electrical steel grade, thinking about grain orientation is important. If the magnetic flux density needs to be high in one direction, grain-oriented electrical steel might be good. But for most motor applications where the field changes direction, non-oriented steel (NGOES) is usually the better choice for the laminations. The choice affects efficiency and core loss.

When you look at electrical steel for motor laminations, you’ll hear about “fully processed” and “semi-processed” steel. What’s the difference? Fully processed electrical steel is ready to use right from the steel mill. The manufacturer has already done all the needed heat treatment, like an anneal, to give it the final magnetic properties. You just punch or laser cut your laminations, stack them, and you’re good to go. This offers ease in manufacture.

Semi-processed electrical steel, on the other hand, needs more work after you make the laminations. The magnetic properties are not fully developed when you get it. After you stamp or cut the laminations, you usually need to anneal them. This heat treatment step is crucial. It helps to relieve stress from cutting and develops the desired magnetic properties, like low core loss and high magnetic permeability. This final anneal is often done in a special decarburizing atmosphere, sometimes with hydrogen, to remove any remaining carbon.

Choosing between fully processed and semi-processed electrical steel depends on your application and manufacturing setup. Fully processed grades are easier if you don’t want to do the final anneal. But semi-processed steel can sometimes offer better magnetic properties after your own careful heat treatment. It can also be better for complex lamination shapes as it’s softer before the final anneal. Both types of steel are important grades of electrical steel.

Selecting the right steel grade for your motor application is a big decision. What does this motor need to do? Is it a high-efficiency motor? Does it run at a high-frequency? What’s the target for core loss? The answers help you select the best electrical steel. The ASTM (American Society for Testing and Materials) provides standards that define different grades. These ASTM standards help compare magnetic properties.

For example, if you need very low core loss for a high-efficiency motor, you’ll look for an electrical steel grade known for that. This often means a silicon steel with a good silicon content and controlled thickness. The manufacturer’s handbook or data sheets are very helpful. They list magnetic properties like core loss (often in watts per pound or watts per kilogram at a certain magnetic flux density like 1.5 Tesla and frequency like 60 Hz), and magnetic permeability.

Think about the operating temperature and the mechanical needs too. Some steel grades handle stress better. You also need to consider how you will manufacture the laminations. Will you punch them or use a laser? Some grades of electrical steel are better for certain cutting methods. Getting this choice right will deliver good motor performance and efficiency. It’s a key part of motor design.

There are many different grades of electrical steel, and it can seem confusing. But we can group them. We have grain-oriented electrical steel and non-oriented steel (NGOES). Within non-oriented electrical steel, there are many grades. These grades are often named using ASTM codes. The codes usually tell you something about the maximum core loss of that steel grade. A lower number often means lower core loss and better quality.

These grades of electrical steel differ in their silicon content, their thickness, and how they are processed. For example, some electrical steel might have around 1% silicon, while others might have 3% or more. The thickness of the lamination sheets can range from very thin (like 0.1 mm) for high-frequency uses, to thicker (like 0.65 mm) for other applications. Thinner laminations generally help reduce eddy current losses, especially at higher frequency.

The alloy composition also includes small amounts of other elements like manganese or aluminum, besides iron and silicon. Each steel grade is designed for certain performance needs. So, when you look at different grades, check their specs for core loss, magnetic flux density, and magnetic permeability. This will help you find a suitable electrical steel for your motor or transformer application. It’s important for the manufacturer to supply consistent grades.

Magnetic properties are extremely crucial when choosing lamination steel for a motor. The whole point of using special electrical steel is for its magnetic properties. We need the steel in the motor core (the stator and rotor) to guide the magnetic field with as little energy loss as possible. Good magnetic properties lead to higher motor efficiency.

Key magnetic properties to look for include low core loss, high magnetic permeability, and high saturation magnetic flux density. Core loss is the energy lost as heat in the lamination steel when it’s magnetized. We want this to be as low as possible. Magnetic permeability tells us how easily the electrical steel can be magnetized. Higher permeability is better. Saturation flux density is the maximum magnetic field the steel can handle before it stops getting much stronger.

These magnetic properties are affected by the steel grade, its silicon content, thickness, and any heat treatment. The manufacturer will test the steel and provide data on these properties. When you select your lamination steel, you’ll compare these values to make sure the steel is used effectively in your motor design to achieve the desired performance. It’s a balance to find the right grade of electrical steel.

This is an interesting question! Amorphous metals, sometimes called metallic glass, are a special type of alloy. Unlike regular electrical steel that has a crystal grain structure, amorphous metals don’t. This unique structure gives them very low core loss, especially at high-frequency. So, for some motor and transformer applications, amorphous alloys can be a big advantage for laminations.

However, there are also challenges with amorphous lamination steel. It’s often more brittle than silicon steel. This can make it harder to punch or stamp into lamination shapes. It can also be more expensive. Because it’s so thin and brittle, handling it during motor manufacture requires special care. The saturation magnetic flux density of some amorphous alloys might also be lower than some high-grade silicon steel.

So, while amorphous laminations offer amazing low core loss and can improve efficiency in certain motor designs, they are not a simple replacement for all electrical steel. You need to weigh the benefits against the costs and manufacturing challenges. For very high efficiency or high-frequency motors, it’s definitely something to consider. This type of steel used can really push performance.

The manufacture of electrical steel for laminations is quite a special processing journey. It starts with melting high-purity iron. Then, elements like silicon (and sometimes others like manganese or aluminum) are added to create the desired alloy. The amount of carbon must be kept very low, as carbon is bad for magnetic aging and magnetic properties.

Next, the molten steel is cast and then hot and cold rolled into thin sheets. This rolling process is very important. For grain-oriented electrical steel, special rolling and annealing steps are used to line up the grain structure. For all electrical steel, the final thickness is carefully controlled. After rolling, the steel often goes through an annealing process. This heat treatment helps to improve the magnetic properties by growing the grain size and reducing stress.

Finally, the electrical steel sheets are often coated with a thin insulating layer. This coating is important because when the laminations are stacked in a motor core, it helps to insulate them from each other. This reduces eddy current losses. The manufacturer must carefully control every step to produce high-quality lamination steel with consistent magnetic properties and mechanical properties. This ensures the steel grade meets standards like ASTM.

The thickness of your motor lamination is a really big deal for motor efficiency! Here’s why: when a magnetic field changes in the electrical steel of a motor, it creates small swirling electric currents called eddy currents. These eddy currents cause energy loss, which shows up as heat. This is a part of core loss.

One of the best ways to reduce these eddy current losses is to use thinner laminations. Think of it like slicing a potato. Thinner slices cook faster. Thinner laminations make it harder for those big eddy currents to form. So, a lamination that is, say, 0.35 mm thick will generally have lower eddy current losses than one that is 0.50 mm thick, especially at higher frequency (like 60 Hz or more).

Of course, using thinner laminations means you need more of them to make up the same core size. This can increase cost and make stacking a bit more complex. But for many motors, especially those aiming for high efficiency or operating at higher speeds or frequency, choosing an electrical steel grade with the right thickness is key. It’s all about balancing performance and cost to get the best result for your specific application. The manufacturer will offer different grades with various thickness options.