Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

If you ride a motorcycle, run a dirt bike, or wrench on small engines, there’s a hidden hero quietly keeping everything alive: the magneto stator. It’s buried behind a side cover, soaked in oil, and it almost never gets any love—until your battery dies on a ride, your lights flicker, or the engine refuses to spark.

At its core, a magneto stator is just copper wire, iron, and magnets. But together, they pull off a neat trick: turning spinning metal into clean, usable electrical power without needing a battery to start with. That’s why magnetos are still used in everything from chainsaws to aircraft engines.

This is where a lot of people (and a lot of blogs) get tangled up, so let’s untangle it right away.

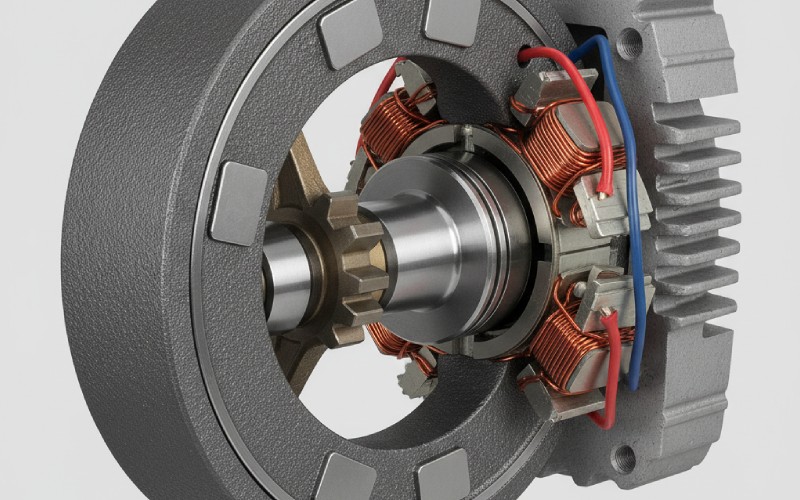

A stator is simply the stationary part of a machine—usually the ring of iron and copper windings that never moves. The rotating part in the middle is called the rotor or flywheel. In motorcycles, the stator plus a spinning magnet is what generates AC power for your lights and battery.

A magneto is a type of alternator that uses permanent magnets on the rotor instead of an energized coil. It generates its own AC electricity as the engine spins, which can be used directly for ignition and/or charging—no external battery needed to excite the field.

Put those together and you get a magneto stator: the stator assembly used inside a magneto-style alternator, built around permanent magnets and copper windings.

Inside your engine case, the crankshaft spins a flywheel that has powerful permanent magnets embedded around its rim. The magneto stator sits just inside that flywheel, lined with copper coils. As the flywheel rotates, its magnetic field sweeps across those coils and induces an alternating voltage in them. That’s pure electromagnetic induction, the same basic principle behind any alternator or generator.

Depending on the design, that AC power is then:

In other words, the magneto stator is the engine’s built-in power plant—no stator, no spark, no charging, no fun.

Let’s slow time down and watch a single crankshaft revolution through the eyes of the stator.

The flywheel passes by with alternating north and south magnetic poles embedded in it. As each pole sweeps past a stator tooth wrapped in copper wire, the magnetic flux through that coil changes. Faraday’s Law says that any change in magnetic flux through a conductor induces an electromotive force (voltage) in it.

When the magnet approaches, flux through the coil rises and a current is pushed one way. As it moves away and the opposite pole comes by, the flux falls and reverses, so the current flows the other way. Do this many times per second and you’ve essentially built a permanent-magnet alternator, right inside the engine case.

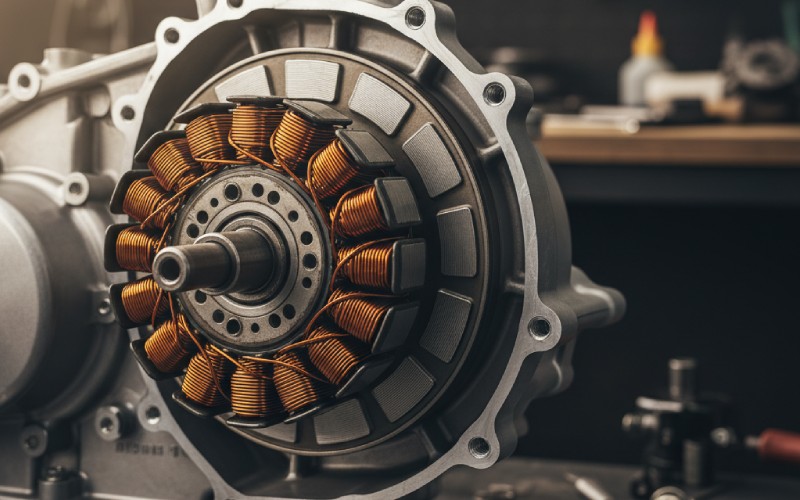

If you pull the side cover off a typical motorcycle or ATV engine and remove the flywheel, you’ll see a circular assembly dotted with copper coils. That’s your magneto stator.

Inside, the construction is surprisingly elegant:

The core is usually made from thin, laminated sheets of steel stacked together. Laminations cut down on eddy current losses and heating. Around each tooth of that core, enameled copper wire is tightly wound to form a coil. Those coils are then wired together in a specific pattern (single-phase, three-phase, split for lighting vs. ignition, etc.). The entire assembly is bolted solidly to the engine case so it never moves.

Here’s a quick comparison you can skim when you’re not sure what someone means by “stator” or “magneto” in a forum post:

| System type | Rotor field source | Stator’s role | Needs battery to make power? | Typical use cases |

|---|---|---|---|---|

| Magneto alternator | Permanent magnets in rotor | Stator coils generate AC directly | No – self-exciting | Motorcycles, small engines, aircraft ignition |

| Car-style alternator | Electromagnet rotor coil | Stator coils generate AC from rotor field | Yes – rotor needs DC | Cars, trucks, large road vehicles |

| “Just a stator” | Depends on the system | Generic name for stationary windings | Varies | Any motor/generator with a stationary winding |

The magneto stator we’re talking about is that first column: permanent magnets, self-exciting, and very happy living inside engines that might not even have a battery.

Not all magneto stators are created equal. If you line up three stators from different bikes, you’ll see differences in size, number of poles, and wiring. Those are all design choices aimed at balancing cost, output, and smoothness.

Common variations include:

On a typical motorcycle with a magneto stator, you can think of the charging and ignition systems as branches growing off the same root—the stator.

As the stator generates AC, part of that energy is sent through a regulator/rectifier, which converts the AC to DC and clamps the voltage to a safe level for the battery and electronics. Another portion (or dedicated set of coils) feeds the CDI/ignition module, which uses the stator’s pulses plus a trigger coil to time and fire the spark plug.

This is why a sick stator can cause both charging problems and misfires or no-start conditions.

Engineers tweaking a magneto stator juggle several factors:

They choose magnet strength, number of poles, wire gauge, and core geometry to hit a target power curve. A stator meant for an enduro bike might prioritize charging at low to mid RPM for trail speeds, while a sportbike stator might lean toward high-RPM output to feed powerful lights and electronics.

Laminations reduce eddy losses, while carefully chosen slot shapes and pole counts help minimize cogging torque and vibration, especially in permanent-magnet machines.

Because the magneto stator sits in a hot, oily, vibrating environment, it can and does fail—usually from insulation breakdown, overheating, or physical damage.

When it starts to go, you’ll often notice a mix of electrical gremlins rather than just one clean failure mode. Stator problems are frequently confused with bad batteries or regulators, so it helps to know the tell-tale signs.

The good news: you can diagnose a magneto stator with a cheap multimeter and a bit of patience.

The basic tests fall into two buckets—static checks with the engine off and dynamic checks with it running. For both, refer to your service manual for exact resistance and voltage specs for your engine, but the principles are widely similar.

A healthy magneto stator will often last the life of the engine, but certain habits and mods can shorten or extend its life.

Stators hate excess heat and overloaded systems. If you’ve added big auxiliary lights, heated grips, phone chargers, and more, you’ve likely pushed the charging system closer to its limit. Pair that with a tired regulator/rectifier or poor airflow, and you can cook the stator windings over time.

A magneto stator isn’t magic—it’s a carefully arranged ring of iron and copper living in the magnetic field of your flywheel. As that field swings past, it pushes electrons around in the coils, creating AC power that keeps your ignition sparking, your battery topped up, and your lights cutting through the dark.

Once you understand how it works and how it fits into the bigger charging and ignition picture, diagnosing problems (or planning upgrades) becomes a lot less mysterious. Next time you thumb the starter and everything comes to life, you’ll know exactly which hidden component is doing the heavy lifting.