Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

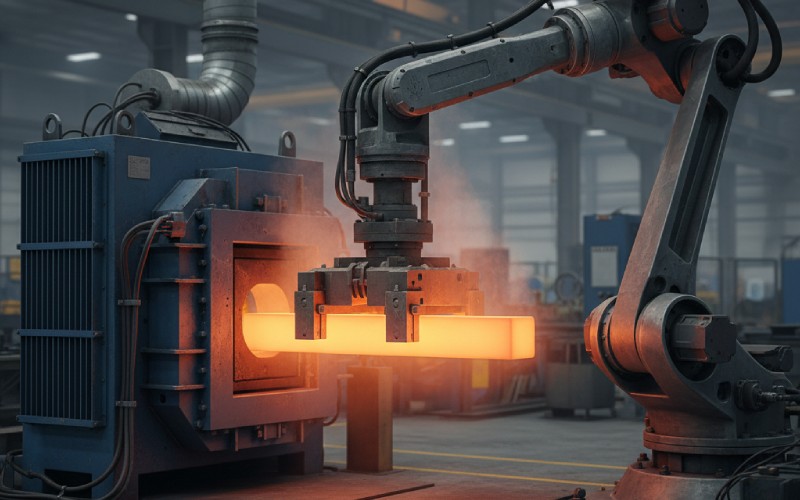

Have you ever asked yourself how a piece of metal can get red-hot in just a few seconds with no fire? It is not a trick; it is science. The name for this is induction heat. This way of heating is quick, clean, and very strong. Many factories and workshops all over the world use it.

This article will show you exactly how an induction heater works. We will use easy words and good examples. You will learn the first things to know about this great technology. You will also find out why it is usually a better choice than old-fashioned heating methods. When you finish reading, you will understand a very important heating tool that is used in businesses today.

The basics of induction heating are easy to learn. Induction heating is a process that is used to heat something that can carry electricity. This is usually a piece of metal. It is a type of non-contact heating. What this means is that no fire or hot object ever touches the part you are heating. Instead, it uses a unique type of energy to generate heat from the inside of the object.

Picture a special coil that is made from a copper tube. An electric current runs through this coil. This makes a magnetic field form all around the coil. When you put a piece of metal into this field, something amazing happens. The field causes very small electric currents to move in circles inside the metal. These currents cause friction and heat. This is the secret to how induction heat works. It is a very direct and energy-saving method of heating.

The science that makes induction heat possible is not a new idea. The history of induction started a long time ago, in the 1830s. A scientist by the name of Michael Faraday found something interesting. He saw that a magnetic field that was changing could induce an electric current in a nearby material that conducts electricity. This is the main idea behind how many things work, from electric motors to the machines that make induction heat.

For a long time, this was just an interesting fact for scientists. But in the early 1900s, engineers figured out how to make this process much stronger. They built the very first induction heating systems. Factories used them to make parts for tanks and planes during wars. From that time on, the technology of induction heating has improved a lot. Today, induction heating is used for many kinds of heating applications.

The most important part of any induction heater is the induction coil. This coil has the biggest job to do. An alternate electric current runs through the coil. This makes a strong magnetic field around the coil that changes very quickly. This special field, the alternating magnetic field, is what begins the heating process. The coil does not get hot on its own. Instead, it makes the work piece you put inside it become very hot.

When you place a conductive material like steel or copper inside the induction coil, two things work together to make induction heat.

An induction heating system is made of more than just a coil. It also needs something to act as its brain and its power. The power supplies do both of these jobs. They take regular electricity from a wall outlet. Then, they change it into the special type of electricity that the induction coil must have. Induction power supplies are a key part of controlling the induction heat.

The power supply is in charge of two main things: frequency and power. Frequency tells you how fast the current switches direction in the coil. Power is the total energy being sent to the coil. Different jobs need different settings. For instance, high frequency induction heating makes heat just on the outside skin of a metal part. A lower frequency induction allows the induction heat to sink deeper into the part. The power supply works with a special part called the tank circuit. Together, they send the correct amount of heating power.

The coil is the most important part for any induction heating work. You can think of the induction heating coil as the main heating tool. The coil’s shape and its size control where the induction heat will go. It also controls how well the process works. A good coil design is the secret to getting a great outcome. If the coil has the wrong shape for the part, you will lose energy and the result will not be good.

The main goal is to make the field generated by the coil focus its energy. It should focus on the exact area of the work piece that you need to heat. For a long, straight rod, a simple round heating coil works best. For a part that is flat, a flat “pancake” coil could be a better choice. The space between the coil and the part is also very important. The part will get more induction heat when it is closer to the coil. The coil generates a very strong current. For this reason, it is usually made from a hollow copper tube. This lets water cooling be used to stop the coil from melting.

A very common job for induction heat is induction hardening. This is a method used to make the outside of a metal part very hard and strong. Parts like gears or axles need a hard surface so they do not wear out. At the same time, you want the inside of the part to be a little softer so it does not crack.

With induction hardening, a specially made work coil is used. It quickly heats only the surface of the part. The induction heat is aimed very carefully. The surface gets very hot in just a few seconds. Right after that, the part is cooled down very fast using water or oil. This fast heating and cooling changes the way the metal is built on the surface, making it very hard. The inside of the part does not get hot, so it stays soft. This gives you the best of both: a tough part with a surface that lasts a long time.

Yes, induction melting is another very important way to use induction heating technology. The same ideas that are used to heat a piece of metal can also be used to melt it. For this kind of work, a strong induction heating system is used. It has a special pot called a crucible. The conductive material is put inside the crucible, and the crucible is put within the coil.

The strong induction heat quickly makes the temperature of the metal go up to the point where it melts. One of the special benefits of induction heating for melting is the way the magnetic field stirs the liquid metal. This stirring action mixes the metal very well. This leads to a higher quality and more even final product. An induction melting system is clean and does not waste much energy. There is very little heat loss when you compare it to older types of furnaces.

When you compare induction heat to older heating methods, like gas furnaces or flame heating, you will see big differences. Induction heating has many good points that make it a better choice for a lot of jobs in the induction heating industry.

Here is a simple chart that shows the main differences:

| Feature | Induction Heating | Traditional Heating (like Flame or Furnace) |

|---|---|---|

| Speed | Very fast. It can heat things in just seconds. | Slow. It can take many minutes or even hours. |

| Energy Use | Works very well. Over 80% of energy heats the part. | Does not work well. A lot of heat loss goes to the air. |

| Safety | Much safer. There is no open fire. It is flameless heating. | Can be dangerous. There is a risk of fire, burns, and bad fumes. |

| Aim | Very exact. Heats only the part you want to heat. | Not exact. It heats the whole part and the air around it. |

| Cleanliness | Very clean. It makes no smoke, dirt, or waste. | Can be dirty. It makes smoke and needs to be cleaned up. |

| Control | Great. It is easy to control the heat and heating time. | Not good. It is hard to control the heat with accuracy. |

As you can see, the benefits of induction heating make it a top choice for making things today. It is a smarter way to use induction heat.

People often ask about the heating depth. How far inside the metal does the induction heat really go? This is a very important question. It is controlled by the frequency of the alternate current inside the coil. Engineers can control how deep the penetration of the heating is very carefully.

The rule is very simple:

By picking the right frequency, an induction system can be set up to heat a part in the exact spot it is needed. This level of control is one of the greatest advantages of induction heating.

We have talked about a lot of good things about induction heat. Let’s put the main advantages of induction heating in a list so they are easy to remember. The use of induction heating provides many good things for workshops and factories.