Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

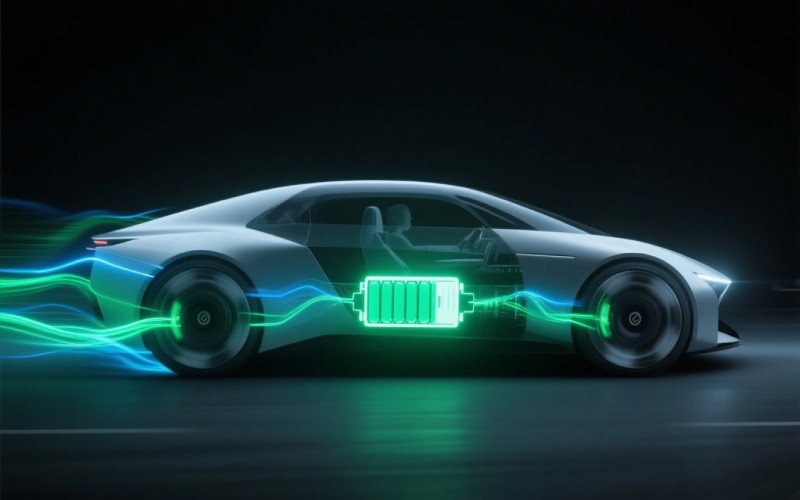

The first time I drove an electric vehicle, I was amazed. It wasn’t the quiet ride or the fast pickup. It was what happened when I lifted my foot off the accelerator. The car started to slow down on its own, and I saw a little gauge on the dashboard show that I was putting power back into the battery. It felt like magic. This is called regenerative braking.

In this article, I’m going to pull back the curtain on this “magic.” We’ll explore how this system works and, most importantly, how engineers measure its efficiency. Why should you care? Because understanding this helps you get more miles out of every charge, save money, and become a smarter electric or hybrid vehicle owner.

Think of it this way. In a normal car with an internal combustion engine, when you hit the brakes, you use a friction brake. This system uses brake pads to squeeze against a disc, creating friction to slow the car down. All the energy of your moving car, its kinetic energy, is turned into heat and is simply lost as heat into the air. It’s a total waste of energy.

An electric vehicle (EV) is much smarter. It has a regenerative braking system that does something amazing. Instead of just wasting that kinetic energy, the regenerative brake captures it. The system uses the car’s own motor to slow it down. This process turns the captured energy into electricity, which then goes back to the battery. So, every time you slow down, you’re putting a little bit of charge back into your car’s battery. This is a very common form of regenerative braking in modern road vehicles. The regenerative brake is a key part of what makes an electric vehicle so efficient.

This is where the real cleverness happens. How can a motor that pushes the car forward also work to slow it down and create power? It’s a simple idea. An electric motor uses electricity to create motion. It has magnets and wires. When electricity flows through the wires, it creates a magnetic field that makes the motor spin and turn the wheels.

When you want to slow down, the regenerative braking system reverses this process. It turns the motor into a generator. Instead of using power, it starts making power. The wheels, which are still spinning from the car’s momentum, now turn the motor. This makes the motor act like a tiny power plant, or an electric generator. This is how the motor as a generator works. The traction motor in an EV is designed to do both jobs perfectly. This process creates a braking force that slows the car down while generating electric energy. The regenerative brake is a beautiful piece of engineering.

When your electric vehicle is moving, it has a lot of kinetic energy. That’s just a science term for the energy of motion. The faster you go and the heavier your car is, the more kinetic energy you have. When you want to slow down, you have to get rid of this energy. The regenerative brake is the first tool your car uses.

When you lift your foot off the accelerator or press the brake pedal lightly, the regenerative braking system kicks in. The electric motor starts to resist the turning of the wheels, creating a braking force. This resistance is what slows you down. The excess kinetic energy is converted into electricity. The system turns energy into electrical energy. This new regenerative energy is sent to the battery to be stored. The amount of energy captured depends on many things, but the regenerative brake is always working to save what it can.

I wish I could tell you that a regenerative brake is 100% perfect, but it’s not. You can’t get back all the kinetic energy you put in. Some energy is lost in the process. Think of it like pouring water from one cup to another; you might spill a few drops. The motor itself isn’t perfectly efficient. It creates a little heat when it acts as a generator. The electronics that control the system use some power, and the battery can’t absorb electric energy perfectly either.

There are other limits, too. If your battery is already 100% full, there’s nowhere for the new energy to go. In this case, the regenerative brake won’t work, and the car will use its regular friction brake instead. The same is true if the battery is very cold, as cold batteries can’t accept a charge as quickly. So, while the regenerative brake is great, regenerative braking may be limited at times. You can’t capture as much energy as you might think, but what you do capture is free. The efficiency of the regenerative braking is a key metric.

This is the main question, and the answer is both simple and complex. At its heart, measuring regenerative braking efficiency is about comparing two numbers: the amount of energy the regenerative brake captures versus the amount of kinetic energy the car lost while braking. The basic formula is: Energy Recovered / Energy Lost = Regen Efficiency.

To get these numbers, engineers use special sensors on the electric vehicle. They measure the speed of the cars to calculate the change in kinetic energy. They also have sensors on the battery to measure exactly how much energy flows back into it during a braking event. They measure the braking power and the braking effort from the regenerative brake. This kinetic energy recovery process is tested over and over in labs and on test tracks to get an accurate number. This helps them improve the regenerative braking system for future cars.

The overall efficiency of the vehicle is not just about the parts in the car. You, the driver, have a big impact on how well the regenerative brake works. If you brake hard and late, the car will need to use its powerful friction brake along with the regenerative brake. This means less kinetic energy recovery. But if you practice using regenerative braking by slowing down gently and looking ahead, you give the regenerative brake more time to work.

Other things matter, too. Driving at a constant speed on the highway doesn’t use the regenerative brake much at all. City driving with lots of stops and starts is where it really shines. The design of the motor and the car’s weight also play a role. Driving downhill is a perfect time for the regenerative brake. It provides excellent control on descending gradients and can act as a net generator of electricity, adding significant range. The use of regenerative braking is a skill.

Hybrid electric vehicles are a special case. They have both an internal combustion engine and an electric motor. This means they can also use a regenerative brake. The system works in much the same way as in a full electric vehicle. When the driver slows down, the motor helps with the braking and sends power to the small battery pack.

Some hybrid vehicles use what is called parallel regenerative braking. This means the car’s computer decides how to blend the regenerative brake and the friction brake to slow down smoothly. The goal is always to use the regenerative brake as much as possible. Regenerative braking in conjunction with the engine turning off at stops is what makes hybrid and electric cars so good for city driving. These hybrid electric vehicles get great energy efficiency from their regenerative braking system.

Many new electric vehicle models offer a feature called “one-pedal driving.” I love this feature. It means the regenerative brake is strong enough to slow the car down significantly, even to a complete stop, just by lifting your foot off the accelerator. You almost never have to touch the brake pedal in normal city traffic. This makes driving smoother and captures the most regenerative energy possible.

However, you always have a normal friction brake system as a backup. This is a critical safety feature. The regenerative brake might not be strong enough for a sudden emergency stop. You need the powerful mechanical braking of a friction brake to shorten the braking distance and keep you safe. Also, if electric braking systems fail for any reason, the friction and regenerative systems work together, but the old-fashioned friction brake is the ultimate failsafe. The regenerative brake alone cannot always bring you to a complete stop in every situation.

The idea of a regenerative brake is not new. In fact, it’s been around for over a century! Some of the first places regenerative braking is also used were on electric railways. Think about it: trains generate large amounts of kinetic energy. Using a regenerative brake to help slow them down and send power back to the grid offered huge economic and operational benefits. Regenerative braking in the early days was a game-changer for electric traction systems.

The idea was even used in early cars. A car from 1900 called the Krieger Electric Landaulet had a drive motor in each front wheel. This electric landaulet had a drive system where the motors worked as generators when the car was going downhill, helping to recharge the batteries. The Krieger Electric Landaulet was ahead of its time. It showed that a kinetic energy recovery system was possible in road vehicles long before modern hybrid electric vehicles came along. Braking in the early 1930s on some electric trolleys also used this principle.

So, after all this technical talk, what does it mean for you? Understanding the regenerative brake helps you in three big ways. First, it extends the range of electric vehicles. By driving smoothly and letting the regenerative brake do its work, you can add miles to your battery charge.

Second, it saves you money by improving energy efficiency. The energy is recovered instead of wasted, meaning you spend less on electricity. It also saves wear and tear on your friction brake pads. Since the regenerative brake does a lot of the work, your mechanical brakes last much longer. This extends the life of the braking system. Finally, it just makes you a better, smoother driver. Learning to master the brake pedal and the regenerative braking effect is a satisfying skill for any EV or hybrid driver.