Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

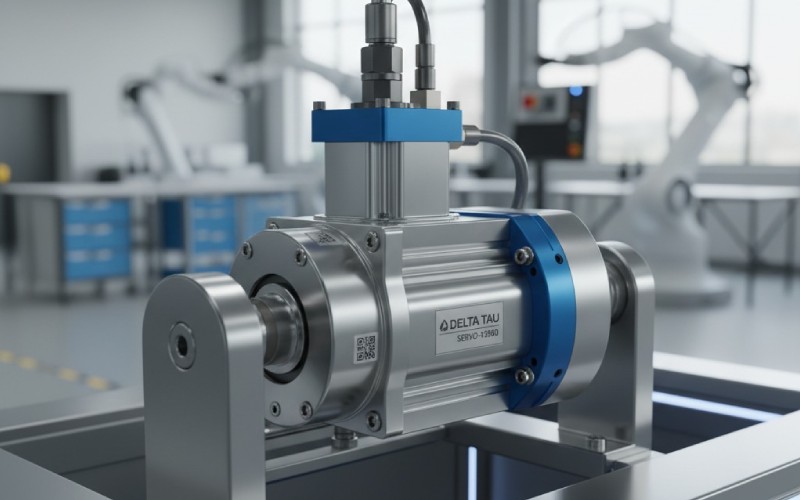

Small but strong servo motors help make machines work by themselves. But how long are these supposed to work? The real answer is that there is no one answer. The lifespan of a servo motor is based on many things. In this article, I will tell you about the things I have learned. I will explain what helps servo motors last a long time and what causes them to break down early. If you read this, it will help you save money. It will also help you stay away from problems and costly downtime.

When we talk about the lifespan of servo motors, it is not only about time. It is also about how hard the motor works. And it is about the place where it works. I have seen some servo motors run for ten years with no problems. I have also seen other servo motors break in less than one year. The most important things are how you use the motor, the place it is in, and how well you care for it. The main parts that get worn out are the moving parts. The bearing is the most common one.

Think of a bearing like the tires on your car. If you drive your car gently on smooth roads, your tires will last for a long time. If you drive fast on rough roads, they wear out fast. A bearing in a servo motor is just like that. Heavy jobs, fast speeds, and a lot of vibration will wear out a bearing much more quickly. A worn-out bearing is a very common reason for servo motor failure. So, the operational lifespan of your servo motors really comes down to these important details.

The name duty cycles might sound hard to understand, but it is a very simple idea. It just means how much a motor is working compared to how much it is resting. Some servo motors are made for continuous duty. This means they can run all day and all night without stopping. Other servo motors are made for short times of work, with rest breaks in between. If you use the wrong motor with a duty cycle for a job, it is a sure way to cause problems.

Knowing about duty cycles is very important for a long lifespan of servo. If your job needs a motor to run all the time, you have to pick a motor made for continuous duty. If the motor only needs to work for short times, you can use a motor with a lower duty cycle. Matching the motor’s duty cycles to what the job needs is one of the simplest ways to make sure your servo motors have a long, good life and do not have problems that lead to overheating.

Over the years, I have seen almost every kind of servo motor failure. Most of them come from a few common reasons. It is almost never the motor’s own fault. The problem is usually with how the motor was put in or how it was used. The main reason for failure is often the bearing. But other things can go wrong too.

Here are the top reasons I see for servo motor failure:

The main cause of servo motor trouble is often a mix of these things. For example, poor ventilation makes a motor get too hot. This heat puts stress on the bearing and the electrical parts. This can lead to an early servo motor failure. Knowing the common cause of servo motor issues is the first step to stopping them.

The short answer is yes. Running servo motors at their top motor speeds all the time will make their life shorter. You can think of it like running a very long race every single day. You might be able to do it for a while, but soon your body would get worn out. It is the same for servo motors. High speeds make more heat and put more stress on the mechanical components, especially the bearing.

Working at high speeds all the time leads to increased wear on the motor bearings. The special grease inside the bearing can break down more quickly because of the higher heat from heat generation. This means there is less oiling. This makes more rubbing and even more heat, which makes the problem even worse. This can lead to the bearing failing too soon.

I always tell my customers to pick a motor that can do the job without running at full speed all the time. Operating at lower speeds, even just a little bit below the top speed, can help extend the lifespan of servo motors by a lot. If your job must have high speeds, you need to be sure you have very good cooling systems. You should also use a high-performance motor made for that type of work. Picking the right motor speeds for your job is a choice between good work and a long life.

The place where a servo motor does its job has a big effect on its life. I have seen servo motors in clean rooms with perfect temperatures last for many years. I have also seen servo motors in hot, dirty factories fail in just a few months. The environmental conditions are very important. The three biggest things to watch out for are heat, contamination, and water.

Heat is a big problem. Servo motors make their own heat when they run. If the air around them is already hot, they cannot cool off. High ambient temperatures and poor ventilation can quickly make them get too hot. This thermal stress can hurt the motor’s electronics and the wire coverings. You must make sure there is good air moving around your servo motors and take care of your cooling systems. Inadequate cooling is a common reason for electrical failures.

Contamination is another thing that can kill a motor. Dust, bits of metal, or oil can get inside the motor. Then, it can get into the bearing. This contamination is like sandpaper. It grinds on the bearing and makes it fail. Using a sealed motor that is right for the work area is important. Water is just as bad. It can cause rust and lead to short circuits and other electrical and mechanical problems. It is very important to protect your servo motors from bad environmental factors to get optimal performance.

A servo motor usually does not stop working all of a sudden. It will often give you warning signs that something is not right. If you know what to look for, you can find motor problems before they cause a big stop in work and costly downtime. Learning the signs of servo motor trouble is a very useful skill.

Here are the most common signs of wear that I tell people to watch for:

When you see any of these signs, do not just leave them. The problem will only get worse. Finding it early lets you plan for a repair. This helps you avoid costly repairs and a surprise servo motor failure. Doing checks for these signs of wear is a simple way to keep everything working for optimal performance.

The great news is that you can do a lot to change the lifespan of servo motors. With a bit of care, you can help your servo motors last for a very long time. It is all about making a good place for the motor to work without stress it does not need. Following good effective maintenance practices is the key.

I have made a simple table of things you should do. If you follow these rules, you can extend the lifespan of your servo motors.

| Do This | Why It Helps |

|---|---|

| Put It In Correctly | Proper alignment of the motor shaft stops extra stress on the bearing. |

| Handle Cables the Right Way | Use good strain relief and do not bend the cable sharply to stop cable failures. |

| Keep It Clean | Stop contamination from dust and water to protect the bearing and electronic components. |

| Make Sure There is Good Airflow | Good airflow and heat dissipation stop thermal stress and getting too hot. |

| Do Regular Checks | Routine inspections help you find signs of wear, like vibration or a loose cable, early on. |

| Check Electrical Wires | Tight electrical connections stop electrical faults and help the servo motor operates well. |

These things do not take a lot of time, but they can make a very big difference. I have seen factories make simple lists for their repair teams to follow. These regular inspections have lowered their number of servo motor failure cases by a lot. It is all about acting before a problem happens instead of after. It is the best way to maintain optimal health for your servo motors.

This is very, very important: you have to pick the right servo motor for the work you need to do. A lot of the problems I see, from getting too hot to premature wear, begin because the motor was not the right one for the job. Choosing a motor that is too small is a very common mistake. A motor that is too small will have to work too hard. It will always be running at high torque and high speeds. This will lead to overheating and increased wear.

But choosing a motor that is too big can cause problems too. A motor that is too big might not work as well. It also might not give you the careful control that you need. The important thing is to carefully figure out the demands of your application. You need to know the speed, torque, and duty cycles that are needed. This will help you pick a motor that can do the work easily, with a little extra power just in case.

When you buy industrial automation solutions, taking time to pick the right servo motor is one of the most important things you can do. It helps you build a system you can count on. Do not just look at the cost. Look at the details and be sure they are what you need. This simple step can stop many hours of costly downtime and problems later on. It is the best way to ensure the servo system has a long life.

A long time ago, we would just wait for a part to break, and then we would fix it. That is a very bad way to run a factory. Today, we have much better ways to do things. Predictive maintenance is one of the best. Instead of waiting for a part to fail, we use tools to guess when a failure might happen. This has a big effect on motor performance and how long it lasts.

Two of the best tools for predictive maintenance with servo motors are vibration checking and thermal imaging. Tools that check for vibration can find very small changes in how a motor is running. These changes can be an early warning that a bearing is starting to have a problem. Thermal imaging uses a special camera to see heat. You can look at your motors operating on the line and see if any are hotter than they should be. This can show you that there is inadequate cooling, electrical trouble, or a bearing that is close to failing.

By using these tools, you can find potential issues before they escalate. You can plan a repair when the machines are already stopped. This is much better than having a surprise servo motor failure stop all of your work. Predictive maintenance helps you maintain optimal performance. It also helps you get the longest possible life from your servo motors. It is about being smart and acting first. It is a plan I suggest to all of my customers who use industrial automation solutions. It is a great way for identifying potential failures.

After all this time, I have learned that the servo motor lifespan is not a secret. It comes from the choices we make. Every choice is important, from when you pick a motor to how you put it in and take care of it. A servo motor is a strong piece of machinery, but it is not something that can’t be broken. It needs our help to last a long time. The goal is to make a work area where the motor runs well, without stress it does not need.

The most common thing that hurts servo motors is stress. This could be thermal stress from too much heat, physical stress from vibration and bad alignment, or electrical stress from a bad power source. Your job is to lower that stress. If you can do that, you can stay away from the pain of costly downtime. The performance and longevity of your servo motors are in your hands.

Do not wait for things to break. Act first. Take good care of your servo motors, and they will take good care of you by working well for many years. These strong parts are at the center of how machines work by themselves today, and they need our care and attention. Taking care of your motors operating in your factory will help you a lot in the long run. These failures can lead to big problems, but they are often easy to stop.