Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

A servo motor makes things move with very exact movement. How does a robot arm know the right place to stop? How does an airplane move its flaps? I learned the answer was the servo motor. In this post, I will tell you what I learned about the way these great tools work. We will look at the feedback mechanism that lets them move so exactly. We will also look at their many industrial applications.

Basically, a servo motor is a special kind of motor. It lets you control the exact spot of its turning part. You can control its angular or linear position. You can also control how fast it moves and speeds up, which are its velocity and acceleration. A regular DC motor just spins and spins. But a servo motor is different. It can be told to go to a certain spot and hold that position.

This skill comes from a smart setup called a closed-loop control system. It works like this: You tell the servo motor a position to move to. It moves there. Then, a sensor inside the motor tells a controller that it is in the right place. This process of always checking is why servos can be so exact. If you are building a robot, a CNC machine, or anything that must move to the right spot, you should learn how a servo motor works.

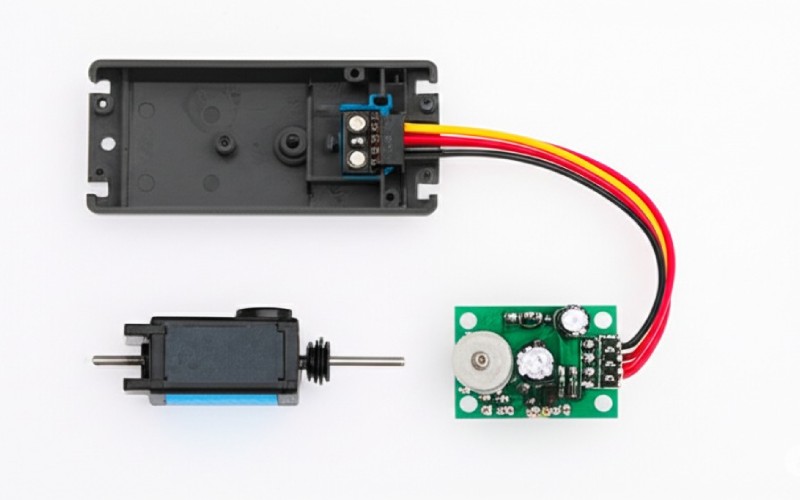

If you open a servo motor, you will see a few main parts that work as a team. It is a small but smart tool.

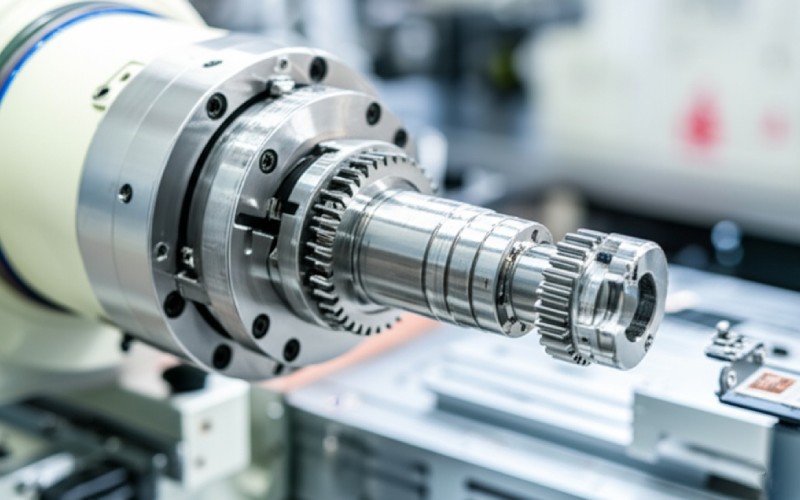

The motor gives the power. The gears give the motor more turning force, which is the torque of the motor. The sensor and control circuit act like the brains. Putting these parts together is what makes a servo mechanism work so well for robotics and automation. The motor shaft connects to the gears. The gears then connect to the turning part you see on the outside.

This is the most special part of how a servo motor works. The idea of a closed-loop control system is what makes servos different from other motors. Think about parking a car. You want to be one foot from the side of the road. You would look to see how far you are, and then you would fix your position. You are using your eyes to check and correct your work.

A servo motor does the same thing. The controller sends a message, or control signal, to the motor. This message tells it to move to a certain spot, which is the desired position. As the motor rotates, the sensor (the potentiometer or encoder) is always reading the position of the shaft. This information goes back to the controller. The controller looks at the current position and the desired position. If they are not the same, it keeps sending power to the motor. It stops when the two positions are the same. This system of always checking and fixing is the feedback mechanism. It helps the servo motor hold its position with great accuracy.

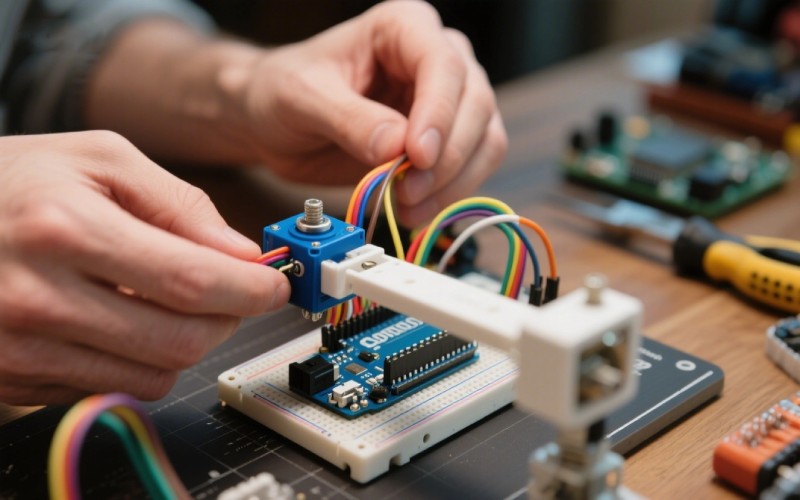

I found out that you cannot just hook up a battery to a servo motor. It will not just start spinning. A servo motor needs a special set of instructions to understand orders. These instructions are called Pulse Width Modulation, or PWM.

A PWM signal is a group of short bursts of electricity. The servo motor expects to get one of these bursts, or a pulse, every 20 milliseconds. The length of the pulse is what matters, not how much electricity it has. The length of this electrical pulse tells the motor’s shaft where to turn.

By sending the right electrical pulse, we can get very precise control of the motor shaft. Many fun projects use controllers like an Arduino. You can add a servo shield to these boards. This makes it easy to control multiple servo motors at once.

When you look for a servo motor, you will see that servo motors come in a few main kinds. The two most common types of servo motors are AC servos and DC servos.

| Part | AC Servo Motor | DC Servo Motor |

|---|---|---|

| Power | Alternating Current (AC) | Direct Current (DC) |

| How It Works | It uses an alternating current to make a spinning magnetic field. | It uses brushes and a part called a commutator, or it can be brushless. |

| Best For | Jobs that need very exact movements, industrial applications, and heavy things. | Simpler projects that cost less, like hobby robotics and small tools. |

| Good Things | Works very well, does not need much repair, has a high torque. | Easy to control, costs less money. |

| Bad Things | It is more complex and costs more. | It is not as efficient. The brushes can get old and cause wear and tear. |

There are also linear servo motors. These move in a straight line instead of in a circle. There are also continuous rotation servos. These can spin all the way around like a normal motor, but you can control their speed. Picking the correct servo motor is based on what your project needs. Think about power, how exact it needs to be, and your budget. For example, big CNC machines often use servo motors that are strong AC servo motors.

In many regular servos, the position sensor is a potentiometer. This is especially true for servos used in hobby projects. A potentiometer is a kind of resistor that can change. It has a knob that you can turn. When you turn it, the amount of electrical resistance changes.

Inside the motor, the potentiometer is linked to the last gear. When the motor shaft turns, the potentiometer also turns. The control circuit passes a voltage through the potentiometer. Then it reads the voltage that comes out. The output voltage is different based on the shaft’s position. This tells the circuit the exact spot of the shaft at any time. This is a simple but good way for the servo system to get its feedback.

For tougher factory jobs, a potentiometer might not be exact enough. For these jobs, a servo motor will use an encoder or a resolver for its sensor.

An encoder is a sensor that changes movement into an electric message. It can tell the controller more than just the position. It can also report the velocity and direction of the motor shaft. There are two main types:

A resolver is another kind of sensor. It is very strong and is often used in places that are rough or dirty. Just like an encoder, it gives feedback about the position of the shaft. Both of these sensors are much more accurate than a potentiometer. That is why you will see them in high-level robotics and automation machines.

After you learn what a servo motor is, you will start to see them in many places. The list of servo motor applications is very long. This is because so many things need to move in a very exact way.

Here are a few places servos are used:

From the first time people used steam to control the rudders on ships to today’s robotics, the main idea of the servo mechanism is still a great way to control a machine.

When I was first learning, I would often mix up servo motors and stepper motors. They are both used to control position. But they do their jobs in very different ways.

A stepper motor moves in small, fixed steps. It does not have a feedback mechanism. You tell it to move a number of steps, and it just does it. It is an “open-loop” system, which means it does