Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

The transformer core is the main part of any electrical transformer. It is the heart that makes the entire thing run. The core directs energy from one coil to another. This lets the transformer change the voltage. This article is your simple guide to this key process. You will learn how to make a transformer core from the beginning to the end. We will talk about the best materials to use. We will also talk about how to get them ready and the steps to put together a strong and good-working core. This guide makes a hard subject simple to learn.

A transformer is a very important part of many electrical devices. Its job is to change the voltage of an electrical current. Right in the middle of every transformer is the transformer core. You can think of this core as a road for energy. An electrical current flows through the first winding. This winding is called the primary. This current makes a magnetic field. The transformer core is made of a special material that directs this magnetic field. This magnetic field, or magnetic flux, is sent over to the second winding, which is called the secondary.

How good the transformer core is becomes very important for the transformer to work well. A good core will move almost all of the energy without losing much. A core that is not made well will lose energy. This lost energy often becomes heat. This is why the design and assembly of the transformer core are so important. The core makes sure the transformer does its job correctly. This core is a key part of the whole electrical system of the transformer. The core’s performance decides how well the transformer works in total.

Picking the right material for your transformer core is a very important step. The material needs to have the right magnetic features. This means it should let a magnetic field go through it with no trouble. The two most usual materials for a transformer core are silicon steel and ferrite. Each material is used for a different use. The right material helps the transformer work very well.

Silicon steel is also called electrical steel. It is a kind of iron that has a small bit of silicon added to it. This steel is very good for power transformers that work with low-frequency power, like the power you find in your house. The silicon inside the steel helps to stop energy loss. Ferrite is a material made from ceramic. It is used in high-frequency electronic transformers. You can find these in computers and TVs. Ferrite is not as strong as steel. However, it has very low loss at high frequencies. Picking the core material is the first step in the making process of any transformer.

| Core Material | Key Features | Common Use |

|---|---|---|

| Silicon Steel | High magnetic strength, good for low frequency | Power transformers, distribution |

| Ferrite | Low electrical loss at high frequency, can break | Electronic devices, computers |

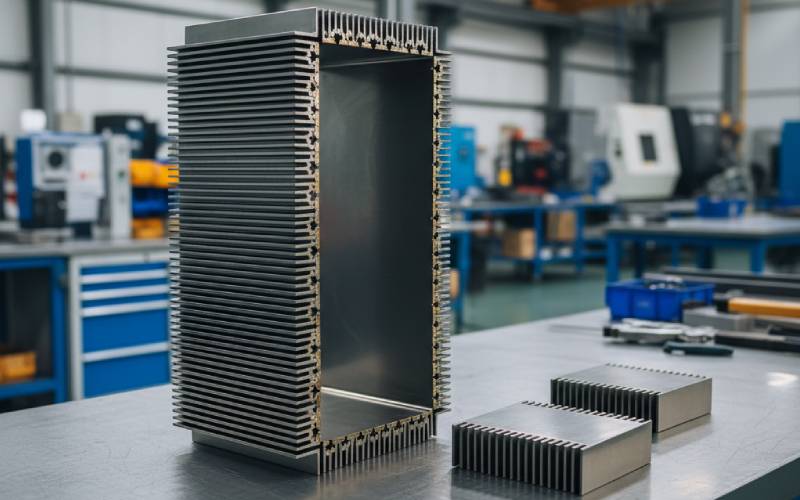

When a magnetic field goes through a solid metal core, it makes small, spinning electrical currents inside the core. This is called an eddy current. This eddy current is not helpful. It only makes heat, which is a way that energy is lost. To stop this loss, we use a special method called lamination. A lamination is a very thin sheet of the core material, like steel. The transformer core is not one solid piece. Instead, it is made by piling up lots of thin lamination sheets. Each lamination is its own piece.

Each lamination has a thin coating on it that stops electricity. This can be a kind of paint or a special layer that forms on the steel. This coating stops the eddy current from moving from one lamination to the one next to it. This method cuts down on a lot of energy loss. It helps the transformer work much better. So, the lamination process is very important for making a great transformer core. One lamination is not very strong. But a pile of lamination makes a strong core. The lamination must be thin to stop current from forming. The whole core is just a pile of lamination sheets.

Before you can put the core together, you need to get the material ready. The main job is cutting the steel or other material into the right shape. Big rolls of electrical steel are put into a machine. This machine cuts the lamination pieces out. The shape of the lamination is important. Usual shapes are “E,” “I,” and “L.” These shapes are made to fit together just right when you assemble the core. The cutting process has to be very exact. This makes sure the final size of the transformer core is right.

After cutting, the edge of each lamination might have small, sharp pieces of metal called burrs. You have to take these off. If the burrs are not taken off, they can cut the insulation coating. This can let eddy currents flow, which makes the transformer work less well. The lamination sheets are then piled up. They are now ready for the assembly process. This readying step is very important to make a top-quality core. This process will make sure the lamination pieces fit nicely.

There are two main ways to put a transformer core together. The way you pick depends on how the transformer is designed and what it is used for. The two types are the “core type” and the “shell type.” The biggest difference is how the core and the winding, or coil, are put together. Both ways use a pile of lamination to build the core. The core assembly method changes how the transformer works.

In a core-type transformer, the winding is wrapped around the core leg. The transformer core looks like a simple box with two legs. The primary and secondary windings are put on one or both legs of this core. In a shell-type transformer, the transformer core is built around the winding. This core has three legs. The coil is put on the middle leg. The shell-type core gives better support for the winding. It can also lower magnetic leakage. Both core assembly types use a special lamination stacking method.

Putting together a shell-type transformer core is a process with several steps. This method often uses lamination pieces shaped like an E and an I. The goal is to build the core around the coil. This process needs you to stack each lamination layer carefully. This is done to make a strong transformer core frame. This is a very popular way to make small transformer units.

Here is the general process to assemble this type of core:

A core-type transformer is also made from lamination pieces. This design often uses L-shaped lamination or shapes like a U and an I. For this core, the winding is put on the core leg after the core is partly built. The biggest difference in this way of building is that you make the legs of the core first. This is a common way to build a transformer core.

The assembly process for this core is like this:

After the lamination stack is finished, the last steps of the core assembly are very important for the transformer’s performance. The goal is to make the core one solid piece. A loose transformer core will shake and be noisy. It can also cause more energy to be lost. To stop this, the core must be held together very tightly. This is an important electrical and mechanical step.

One popular way is to use a metal clamp or a frame. The whole core assembly is put in the frame. Then, bolts are tightened to squeeze the lamination stack together. This gives more strength to the core. Another way is to use a special glue. A special epoxy resin can be used to coat the whole core. The epoxy resin gets in between all the lamination pieces. Then it gets hard and glues the whole transformer core, making it one solid block. This process can also help to lower noise and make the electrical parts work better. These final steps make sure the core will work great.

A perfect transformer would move all of the energy from the primary to the secondary winding. But in real life, some energy is always lost. A lot of this loss happens in the transformer core. There are two main kinds of core loss: eddy current loss and hysteresis loss. Knowing about this loss and trying to lower it is very important for making a transformer that works well. A system that works well saves energy.

As we talked about before, eddy current loss happens because of small electrical currents inside the lamination. Using a thin lamination helps to lower this loss. Hysteresis loss is different. It is the energy that is used to change the direction of the magnetic field in the core material. This happens with every cycle of the current. The choice of core material, like silicon steel, is picked to lower this kind of loss. Good magnetic features, like high permeability (which means how easily a magnetic field can pass through), help lower this loss. Less loss means it works better. It also means less heat comes from the transformer. How well the transformer works depends on keeping the energy loss small.

So, in the end, making a transformer core is a job that needs care and accuracy. It is more than just piling up pieces of steel. Every step, from picking the material to the final assembly, greatly affects how well the transformer works. The transformer core is the heart of the transformer. How good it is decides how well the whole electrical device works.

The core material needs to have great magnetic features. This helps it direct the magnetic flux with very little loss. The lamination process is a smart method used to fight energy loss from eddy currents. Lastly, the assembly method, if it is for a core-type or shell-type transformer, has to be done very carefully. This is to make a tight and solid core. By doing these steps, you can make a top-quality transformer core. It will give power to electrical devices in a way that works well for a long time. This whole process is a key part of making transformers.