Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Picking the wrong servo motor is an easy mistake to make. But it can cost you time and money. It can also cause a lot of problems. This article is my guide to help you stay away from those issues. I will show you the main things you need to think about. We will talk about everything from speed and torque to inertia and software. When you finish reading, you will know how to select a servo motor that is the right choice for your job.

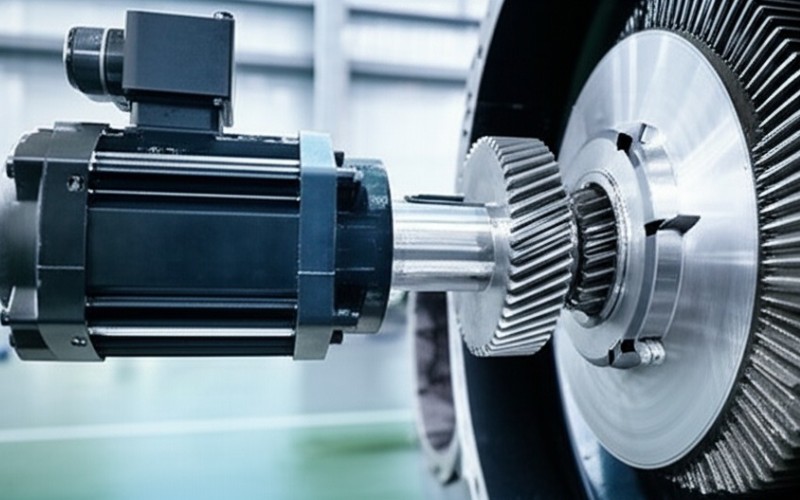

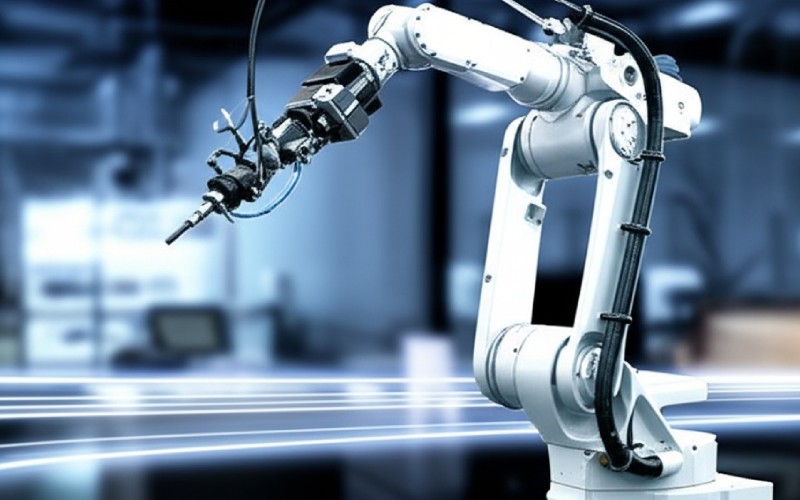

Let’s begin with the simple facts. A servo motor is a special kind of electric motor. It is made for very exact control of its place, its speed, and how fast it gets up to speed. Picture a robot arm in a factory. It needs to move to the very same spot over and over. That is a job for a servo motor. It uses a feedback tool, like an encoder. This tool tells a controller where it is. This makes its movements very exact and something you can count on.

You cannot have a servo motor without a servo drive. The servo drive is like the brain for the whole system. It gets a command, like “move to spot X at Y speed.” Then, it sends the right amount of voltage and power to the servo motor to make that happen. The servo drive also checks the feedback from the motor. This makes sure the motor is doing what it was told to do. A good servo drive and servo motor working together are the starting point for any great motion control system.

The very first step is to know all about your application. Before you even look at one servo motor, you have to lay out what you want to do. What is the purpose of your machine? What are you trying to move? This is the most important part of the whole process. A mistake at this point will cause issues down the road. For your exact application, you need to find out all of the details.

Ask yourself these questions about your application:

Describing your application in a clear way gives you a list of things you need. This list is your guide. It will help you as you select the correct servo motor for your automation application. This is the base for a project that works well. If you don’t have a clear idea of the application, you are really just making a guess.

After you understand your application, you need to work out the speed and torque. Torque is a turning force. You can think of it as the “strength” that the servo motor needs to have. Speed is about how fast the motor must turn to make the movement happen in the time you have. You must calculate these numbers for your exact application.

You need to know about two kinds of torque for your application:

| Torque Type | What It Means |

|---|---|

| Continuous Torque | This is the amount of turning force the servo motor can make all day without needing to stop or overheat. This is also known as the rated torque. |

| Peak Torque | This is the most turning force the servo motor can make for just a short time. You need this to get the load moving (acceleration) or to stop it in a hurry. |

You will need to figure out the torque requirements for each part of the movement cycle. This means finding the torque needed to accelerate the load. It also includes the torque needed to move at a steady speed (to beat friction). And you need the torque to slow things down. The highest amount of torque needed at any moment will be your peak torque requirement. The average torque over the whole cycle helps find your continuous torque requirement. Knowing your speed and torque requirements is a very important step to select a servo motor.

Inertia is a word that might sound hard to understand, but the idea is not. Inertia is how much an object does not want to change its speed. A heavy ball has more inertia than a light one. It is harder to get it started and harder to get it to stop. In a servo system, we care about the inertia of the load. We also care about the inertia of the servo motor’s moving part, the rotor. The link between these two is known as the inertia ratio.

Correct inertia matching is very important for the system to work well. The inertia ratio is the load inertia divided by the motor’s inertia. A good general rule is to keep this ratio under 10-to-1. For instance, if the motor inertia is 1, you would want the load inertia to be 10 or less. If the ratio is too high, the servo motor will have a very difficult time controlling the load. It is like trying to control a very heavy object with a very small muscle. The system might go past its target, shake, and have a hard time being exact.

A bad inertia ratio is a common challenge. You can calculate the load inertia based on the shape and weight of every moving part in your application. If your inertia ratio is too high, do not worry. There is a great solution. Using a gear reducer is a great way to make the inertia matching better. This simple component can make a very big difference in how well your servo motor can handle the load.

Every servo motor has a speed-torque curve. This chart is one of the most important tools you will use. The curve shows you what the servo motor is able to do. It tells you how much turning force the motor can make at different speeds. The company that makes the motor gives you this curve for every servo motor they sell.

The speed-torque curve has two main parts:

When you select a servo motor, you have to look at its curve. You need to be sure that your continuous torque requirement is inside the continuous region. You also need to check that your peak torque requirement is inside the intermittent region of the curve. If what you need is outside the curve, then that servo motor is not a good fit for your application. The curve gives you a clear yes or no answer about what the motor can do.

Many jobs do not just run at a single speed and a single torque. They have a complex motion profile. A motion profile tells the story of all the moves the motor does in one full cycle. It might accelerate, then run at a steady speed, and then slow down. The torque is different all through this profile. So, how can you tell if the servo motor will get too hot? You have to calculate the RMS torque.

RMS stands for Root Mean Square. It sounds hard, but it is just a method to find the average torque over the whole motion profile. It is a special kind of average. It takes into account the heat made by the motor’s power. Think of it as a time-weighted average. It gives more importance to the high-torque parts of the cycle. This RMS number shows the constant torque that would create the same amount of heat in the servo motor.

After you figure out the RMS torque number for your motion profile, you must check it on the motor’s speed-torque curve. The RMS torque you found, at the average speed, must be inside the continuous region of the curve. This is a very important check. If it is outside the continuous area, the servo motor will slowly get hotter and hotter. After some time, it will overheat. Good sizing software can do this RMS calculation for you. This makes this key step much simpler.

Sometimes, a servo motor by itself is not the top solution. In many industrial automation solutions, we use a gear reducer, also known as a gearbox. A gear is a mechanical tool that swaps speed for more turning force. For example, a 10-to-1 gear ratio will lower the output speed by 10 times. But it will make the output torque 10 times bigger (after a small loss to efficiency).

There are two main reasons to use a gear:

Yes, the physical size of the servo motor really does make a difference. This is a real-world thing to think about that you cannot forget. After you have looked at the torque, speed, and inertia, you must check to see if the servo motor will really fit in your machine. A motor that is too big might work well, but it is no good if you cannot put it where it needs to go.

Before you make your final choice, get the drawings for the servo motor and its gear, if you plan to use one. Look at the measurements carefully. Compare them to the space you have in your machine design. Do not forget to leave room for the cables and plugs, because they also need space. Good alignment of the motor shaft to the load is also very important for a long and problem-free life.

Another reason size is important has to do with cost and efficiency. A bigger motor is not always the better choice. An oversized servo motor costs more money to buy. It also uses more power to run. It will also have a higher rotor inertia. This could make your inertia ratio worse if your load inertia is very small. The main goal is to select a servo motor that is just the right size—not too small, and not too big. This is how you get a design that is efficient and a good value for the money.

Besides the main things like torque, speed, and inertia, there are other items to think about. These details can make a large difference in how well your automation application works out. One important factor is the environment where it will work. If your machine will be in a very hot or cold location, you have to pick a servo motor that is made to handle that temperature. If the environment has things like dust or water, you may need a motor with a special seal to keep it safe.

Another key factor is the voltage you have. What is the input voltage at your building? Servo drive systems are sold with many voltage ratings, like 120 VAC, 240 VAC, or 480 VAC. You need to select a servo drive and motor system that works with the power you have. There are also DC powered systems. These are often used in mobile or battery-powered automation applications.

Last, think about the feedback tool. Most new servo motor choices are brushless AC motors that have high-resolution encoders. The encoder tells the servo drive the exact spot of the motor shaft. The better the resolution of the encoder, the more exact the control will be. For most jobs, a normal encoder is fine. But for an application that needs very smooth movement at a very low speed (low velocity), you might need a special encoder with a higher resolution.

A long time ago, we had to do all these calculations with a pen and paper. It used a lot of time and it was easy to get something wrong. These days, things are much simpler. Most companies that make servo motor and servo drive products give away free sizing software. This software is a wonderful tool. It can help you select the very best servo motor.

This software helps you through the whole process. You type in all the information about your application. This includes the weight of your load, the moves you need to make (the motion profile), the mechanical parts like screws or belts, and the cycle time. The software then does all the difficult work for you. It will calculate the speed, peak torque, and RMS torque. It will also calculate the load inertia.

The software then looks through all the products the company sells. It will give you a list of servo motor, servo drive, and gear sets that will work for your application. It will show you how much extra power each choice has. This helps you select a dependable solution with a good amount of safety room. Using this software is the top way to be sure you have done the job of selecting the right servo correctly.