Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Motors are the hard workers we don’t always see. They are in your power drill and your kitchen blender. They are also in your washing machine and your car. But not all motors are made the same way. Two types you see a lot are the induction motor and the carbon brush motor. Learning the difference between them can help you. You can pick the right tool for your job. You can also understand why the things you use at home work the way they do. This article will explain it all in a simple way. We will look at them side-by-side. This will help you see which one is better for different jobs.

Let’s begin with the simple facts. A carbon brush motor is a type of DC motor you see a lot. “DC” means Direct Current. This is the kind of power that comes from a battery. The most important part of this motor is the brush. These are not the kind of brushes you clean with. They are little blocks made of carbon. They push on a part of the motor that spins.

The job of the brush is to carry electric power, which is called current. It takes this power from the power supply. It sends it to the part of the motor that needs to rotate. These motors are easy to make. Because of this, they are in all sorts of things. You can find them in a hand drill, a mixer for your kitchen, or a little toy. The simple design means it is used a lot for many jobs. This motor is a really hard worker in tools and gadgets.

Now, let’s look at the other kind of motor: the induction motor. This motor is not the same because it uses AC (Alternating Current) power. This is the kind of power you get from a plug in your wall. The biggest and most important difference is that an induction motor does not have any brushes. This is why some people call them “brushless motors.”

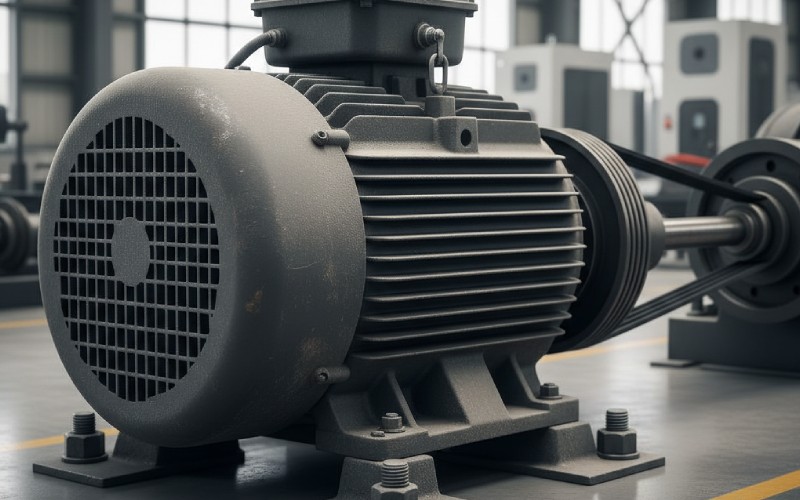

So, how can it work with no brush? An induction motor uses the power of magnets. It has a part that doesn’t move, and this part is called a stator. When power goes to the stator, it makes a spinning magnetic field. This is a force you can’t see. This force makes the spinning part of the motor, the rotor, rotate. The parts spin without ever touching each other. It’s a very smart design. It is used in many bigger machines, like washing machines and machines in factories.

The main difference in how these two motors spin is the method they use. The key is how they get power to the parts that move. The action is totally different for an induction motor and carbon brush motor.

In a carbon brush motor, parts are physically touching each other. The carbon brush touches a part named a commutator. The commutator spins, and the brushes slide on it. This sends a DC current to different areas of the rotor. This touching is what makes the motor rotate. It is a simple system that works well. It has been used for a very, very long time.

The induction motor is more high-tech. It uses an idea called electromagnetic induction. The stator makes a strong, spinning magnetic field. This magnetic field then makes a current inside the rotor, which is a conductor. This new current makes its own magnetic field. The two magnetic fields then push and pull on each other. This makes the rotor rotate. It tries to spin as fast as the field from the stator. It feels like magic because the parts spin but do not touch.

Yes, they do need upkeep. This is one of the biggest problems with a carbon brush motor. The brush is always rubbing on a part that moves. Because of this, it gets smaller over time. You can think of it like the rubber on a car tire. After a while, the brush will be all used up. Then it will need to be changed. If you do not change it, the motor will not work anymore.

This means you need to do maintenance on the motor and carbon brush motor. You might also have to clean the carbon dust that gathers inside the motor. An induction motor, however, has no brushes that can get used up. This helps it have a very long life and a low maintenance cost. This is a big reason they are picked for applications that require running for a long time without a break.

If you have used a power drill, you know it can make a lot of noise. Much of that noise is from the motor. The noise from a carbon brush motor happens because the carbon brush rubs on the spinning commutator. This makes a special buzzing or whining sound. It gets louder when the speed goes up.

An induction motor is a lot more quiet. Because no brushes are touching, it runs much more smoothly. The only noise you usually hear is a soft hum from the magnetic field. You might also hear the bearings. For things in your house where you want low noise, like air conditioners or a refrigerator, the induction motor is a great choice. The noise level is very low.

This is where things get interesting. Torque is the twisting power a motor makes. It’s the power a drill uses to push a screw into hard wood. A carbon brush motor is very good at making torque. It can give you a lot of torque as soon as you turn it on.

This fast start-up and power right away is why the carbon brush motor is great for power tools. When you press the button on a drill, you want that power now. An induction motor has strong and even torque. But it takes a little longer to get to its full power. It is known for its high output power when you are using it without stopping. This makes it good for machines that run at the same speed.

Changing the speed of a motor is a big deal for many tools and machines. The speed of a DC motor, like the carbon brush motor, is very simple to control. You just change the voltage from the DC power supply. More voltage gives you more speed. Less voltage gives you low speed. This is why lots of hand tools have a trigger that lets you change the speed.

It is harder to control the speed of an induction motor. Its speed has to do with the frequency of the AC power supply. In most houses, this frequency does not change. To change the motor’s speed, you need a special electronic part. This part is called a variable frequency drive (VFD). This part can change the power frequency. But it makes the system more complicated and costs more money.

To get very exact control over a motor’s speed and torque, we use electronics on a circuit board. For a simple DC motor, a part you see a lot is an h-bridge driver. This lets you make the motor go forward and backward.

For more control, people who build things might use an integrated motor driver. A special chip, like the mc34933 from a company like TI, can be put on a special board. For example, the 【designs】frdm-34933evb is a freedom expansion board that gives engineers great control. It lets you do things like current regulation and stall detection (which tells you if the motor is stuck). You can even measure the current sense output. This helps you see how hard the motor is working. This gives good protection for the whole machine. This type of control lets you make very smooth moves, which is called microstepping. This can be used in a camera joint or a 3D printer. The protection circuitry is a very important part of a new motor system.

When you look at the price, there is a big difference. A carbon brush motor costs less. Its simple design means it is easier and cheaper to make during production. This is what helps keep the cost of many hand tools low.

An induction motor will almost always cost more to buy at first. But, it can be a better choice over time. It has no brush to change and needs almost no maintenance. So, how much it costs you over its whole life is very low. It is built strong and has a long life. This makes it the right choice for an important machine that you will need to count on for many years.

You will find a carbon brush motor in many things you use every day. You see them a lot in a hand tool. Here are some common places you see them:

These are a good fit for jobs that need a lot of power in a small space, even if they make some noise. They are often used for jobs that are done often, but not all day long.

The induction motor is the best for jobs that go on for a long time. It is not like a gas engine. An electric motor is quiet and clean. The induction motor is the most quiet and clean of all. Here are some jobs where they work best:

| Where It’s Used | Why an Induction Motor is a Good Choice |

|---|---|

| Washing Machines & Dryers | Quiet running and long life for every day use. |

| Refrigerators & Freezers | Must run for years, be something you can count on, and have low noise. |

| Fans & Air Conditioners | Smooth, quiet, and runs without stopping. |

| Pumps and Compressors | Power you can count on for moving water or gas. |

| Large Mechanical Equipment | Used in factories and on industrial production lines. |

These are applications that require running quietly and being something you can count on. They can run for hours, days, or even years. The induction motor is made to last a long time. The choice between an induction motor and carbon brush motor will always depend on the job it has to do. Each has its own good points and the right jobs for them.