Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

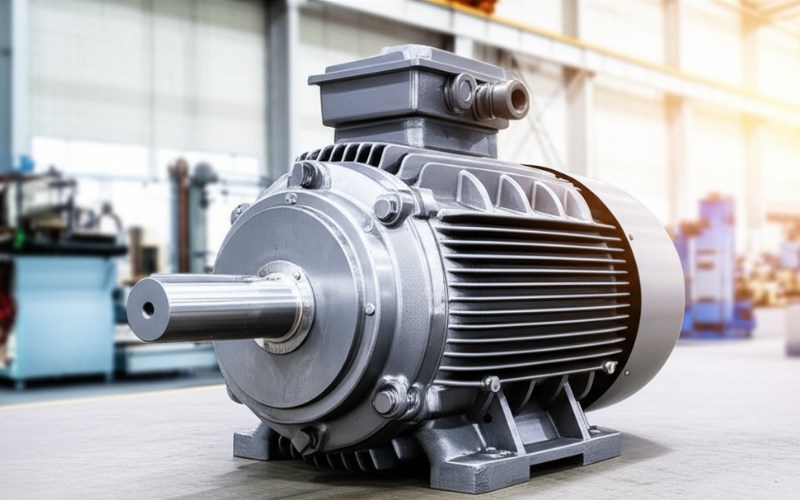

A sudden motor failure can close down your entire procedure. It sets you back a great deal of cash and time. This guide is everything about exactly how a simple electric motor inspection can conserve you large headaches.

Reviewing this will aid you keep your industrial electric motor in leading form and avoid pricey downtime. It’s all about good motor upkeep .

An ounce of avoidance is worth an extra pound of remedy. This is so real for any motor . Taking time for regular examinations can quit a small issue before it becomes a huge problem . A sudden motor failure can stop your center . That means lost time and money. Great upkeep techniques are vital. A careful inspection belongs to that, and it’s something you must execute vigilantly. When we evaluate our devices commonly, we capture things early. Possibly a bearing is wearing out, or insulation shows signs of deterioration. Early indicators indicate a smaller sized repair . Your motor maintains running. This inspection enhances dependability . Trust me, a great inspection schedule is wise for any industrial electric motor .

What should you inspect when you perform an electric motor inspection ? Take a look at the motor . Is it tidy? Dust and particles can make it run warm . This causes insulation deterioration and very early failure . Make sure air vents are clear so the unit can cool per its layout . Also, pay attention to uncommon sounds. Grinding can be a sign of bearing trouble or various other internal concerns . Feel the motor body surface area (meticulously!). Is it too hot ? A basic inspection supplies much info about its problem . You need to additionally smell around the motor . Does it scent like burning or overheating? This sensory examination is a quick way to spot potential trouble .

Just how frequently should you do an inspection ? It depends on the motor and its application . For vital equipment , examine it regularly. A visual inspection and listening examination once a month benefits lots of systems in a center . For comprehensive maintenance and inspection , like examining lubrication , every 6 months is an usual timetable . You must likewise perform more comprehensive checks every 6 months . A consistent inspection routine is key. It assists make sure no motor fails to remember. Companies like Duke Electric can aid set up a preventive maintenance schedule. This keeps your operation smooth. The objective of the inspection schedule is to catch issues prior to major failure . Routine evaluations are vital. Industrial electric motors can last long if looked after properly .

Really feeling a motor to see if it’s warm is a quick inspection. However, what’s ‘as well warm? Most motor designs have a max operating temperature level (on the nameplate). If a unit runs above its rated temperature level , it’s a clear sign of trouble . High temperature levels reduce insulation life. Utilize an infrared thermometer for exact temperature analyses. High temperature levels can originate from bad cooling, overload, or a falling short bearing . Regular temperature checking throughout inspection helps place destruction early. If a motor is always at a high temperature , check out. This inspection step is essential.

Let’s talk lubrication. This is crucial for motor health. Bearings require the right amount of the right lubricant. Insufficient lubricant (often grease for bearings), and the bearing overheats and fails. Too much lubricant also creates issues! It can lead to high temperatures in the bearing or enter windings, causing damage. This is a common problem. Your upkeep team ought to adhere to the manufacturer’s suggestions for lubrication . This includes lubricating substance kind (a specific grease ), amount, and re-greasing regularity. An inspector must inspect for old oil or signs lubrication is required. Proper lubrication protects against failure and makes sure equipment last. The lubricating substance problem is a great indicator.

Our ears are wonderful for a motor inspection ! An efficiently running unit has a consistent hum. New or uncommon sounds need interest. Whirring, grinding, or knocking can be a very early sign of problem, typically with a bearing or various other relocating components . During regular assessments , pay attention. If you have a brand-new operator in the center , educate them what tools should sound like. Educating your team to find these modifications can protect against a little issue from ending up being a big failure . Do not ignore unusual noises; they often indicate a motor needs closer inspection or solution .

A great aesthetic inspection is key for motor maintenance . Consider the motor housing for cracks or damage . Check mounting bolts and each electrical joint and mechanical joint to guarantee they are tight. Loose connections cause vibration. Look for overheating signs on the motor body surface , like tarnished paint. Inspect the area around the system. Buildup of dirt can block air movement, increasing temperature level . A clean motor is enjoyable. These aesthetic checks, done consistently , expose much concerning your device’s problem and aid protect against downtime. This inspection type is quick but useful.

Appropriate storage space for a spare motor is essential. Otherwise saved right, it can have problems. Dampness damages insulation and bearings. Store units in a tidy, dry place. The storage location temperature level issues. You ought to additionally maintain storage records as a component of your inspection regularly. Rotate the shaft of a stored motor by hand periodically. This keeps lubricant in bearings and prevents flat spots on bearings (or brinelling). Good storage methods make sure spare remains in excellent functioning condition . This step in your maintenance preparation for storage saves problems. It belongs to a complete inspection process for devices .

Occasionally, call professionals. Your inspection might find a potential problem you can’t deal with, or you require specialized monitoring. Businesses like Duke Electric have tools for complex motor issues. They can execute examinations like motor current signature analysis or inspect insulation resistance . If a motor requires significant repair , or you’re uncertain of its problem , obtain specialist service . Duke Electric can also assist with a complete preventive maintenance routine for your facility . Don’t wait on failure ; expert aid from a group like Duke Electric makes sure integrity and long life for your devices . This positive service usually has a reduced general cost than reacting to a failure .

Past basic checks, advanced monitoring exists. Vibration analysis reveals a motor’s internal condition . If a rotor bar or end-ring has an issue , resonance analysis might find it. Specialists, like from Duke Electric, typically perform this as part of predictive maintenance . Insulation resistance evaluating checks winding health. Low resistance can indicate insulation is breaking down, risking a short circuit. These examinations provide information for wise choices on motor service or replacement. Such checking stops failure and keeps your center running . It’s a clever investment to make sure your motor lasts. A routine schedule for this comprehensive inspection on essential devices is great.