Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

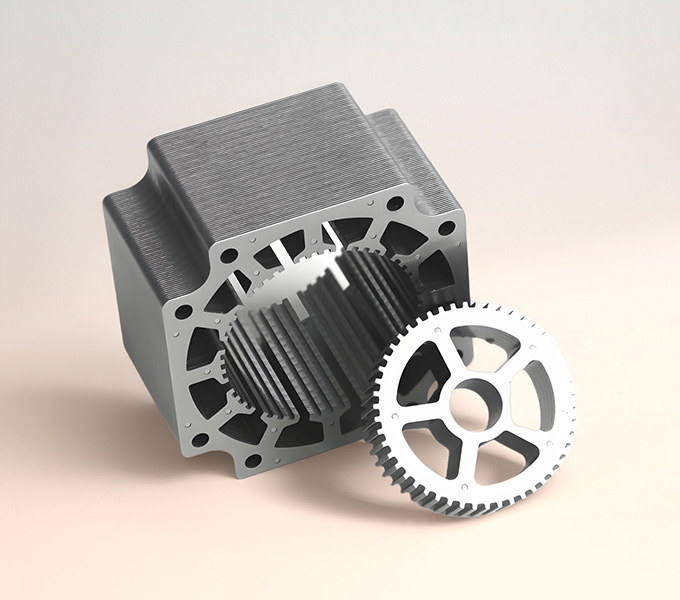

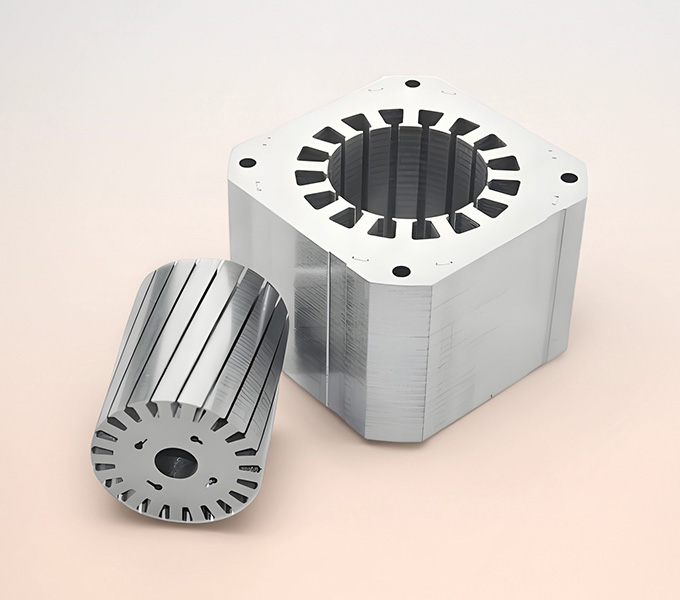

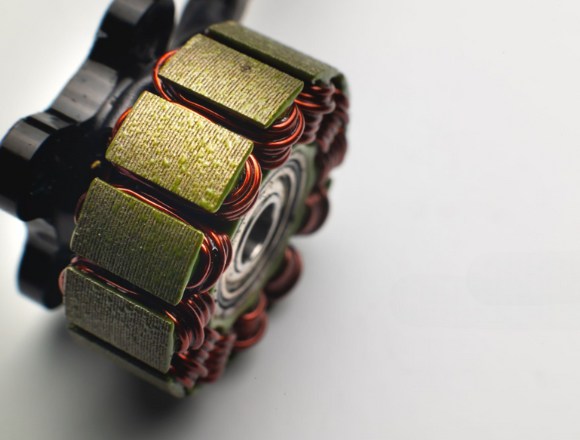

At Sino, we are leaders in developing new electric machine parts, and we focus on designing and making high-quality motor core laminations. As a top Chinese maker, we serve many different customers around the world. We help motor makers in many fields—from the fast-growing electric vehicle (EV) sector to strong industrial uses, exact aerospace systems, and everyday consumer electronics. Our goal is to provide the basic parts that make the newest electric motors more efficient, powerful, and reliable.

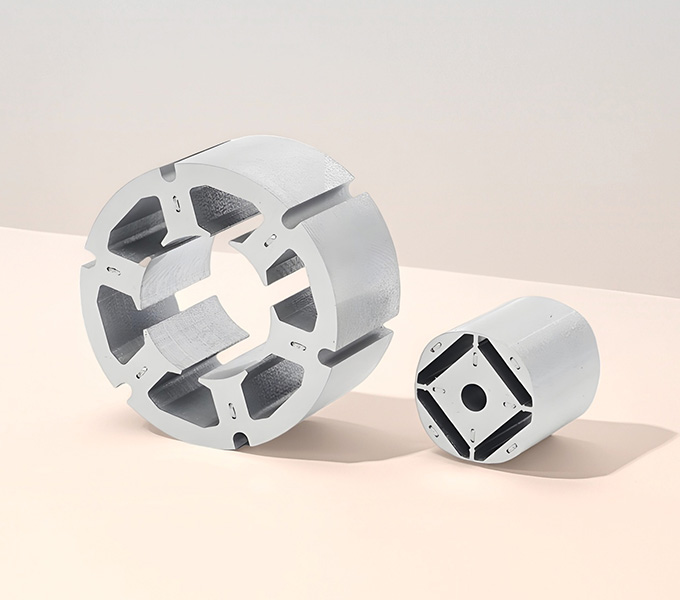

Beyond Basic Iron: How well a motor core works is closely tied to the science of the materials used for its laminations. At Sino, we use our deep knowledge of magnetic, mechanical, and heat-related properties to pick and work with the newest materials. This makes sure our customers get the best results for their different uses.

At Sino, we utilize specialized electrical steels, often referred to as silicon steel. Silicon steel is still the main material for motor core laminations, making up over 80% of the market. Adding a small percentage of silicon (typically ranging from 1% to 4%, though sometimes higher for specific needs) to iron does a couple of wonderful things. Firstly, it significantly increases the material’s electrical resistivity, which gives an extra helping hand in suppressing eddy currents. Secondly, it alters the steel’s crystalline structure, making it easier for those tiny magnetic domains to flip back and forth. This reduced “magnetic friction” directly translates to lower hysteresis losses.

Let’s look at a simplified comparison:

Table 1: Sino’s Perspective on Core Material Choices & Their Impact

Feature & Sino Focus | Standard Carbon Steel (Solid – Hypothetical for Motors) | Sino Non-Oriented Silicon Steel Laminations | Sino Grain-Oriented Silicon Steel Laminations (Thinner) |

Lamination Thickness (Sino Range) | N/A (Solid & Inefficient) | 0.35mm – 0.65mm (Common Sino Offerings) | 0.18mm – 0.35mm (Sino High-Performance Options) |

Eddy Current Losses (Relative) | Sky High | Low | Very Low |

Hysteresis Losses (Relative) | High | Low to Moderate | Ultra Low (in grain direction) |

Sino’s Contribution to Core Loss Reduction | (Baseline – Not Recommended) | Excellent | Superior (for specific flux paths) |

Typical Sino Motor Scenarios | — | Versatile: Industrial Motors, Appliances | High-Efficiency Motors, Specialized Applications |

(This table is illustrative. Sino offers a wide range of material grades and thicknesses tailored to specific customer requirements.)

The selection of the right grade of electrical steel, its careful handling to preserve magnetic properties (avoiding undue stress, for example), and precision stamping or laser cutting are all part of Sino’s commitment to delivering a superior motor core lamination.

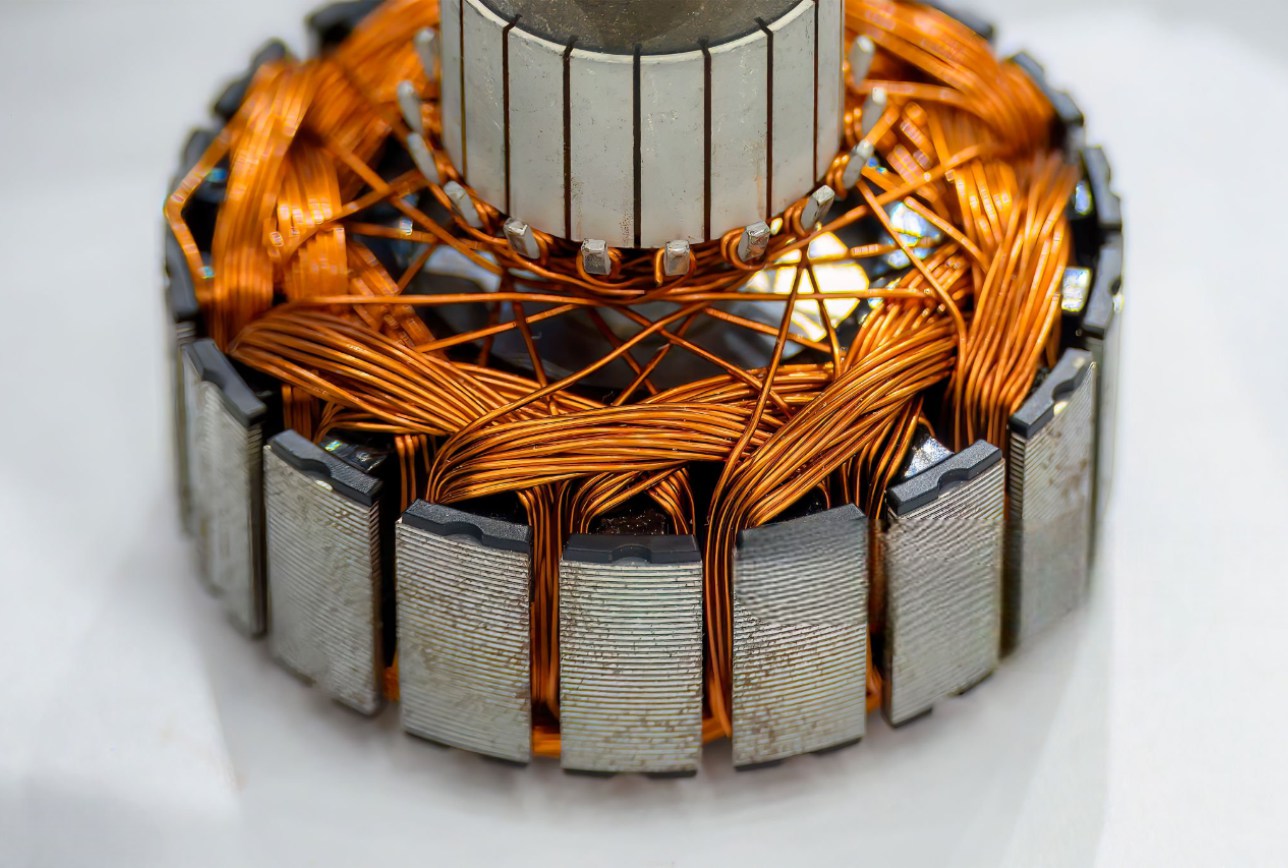

Less energy wasted as heat directly translates to more electrical energy being converted into useful mechanical work – the actual turning of the shaft. For any scenario where motors run for extended periods, from factory automation to your home air conditioning, the energy savings from a high-efficiency motor built with quality motor lamination stack components from Sino can be substantial over its lifetime.

Lower core losses inherently mean less heat generation.This means the insulation on the copper windings lasts longer, as excessive heat is a primary cause of insulation breakdown and motor failure.It can reduce or even eliminate the need for bulky and expensive cooling systems (like fans or liquid cooling), making the overall motor design more compact and cost-effective.Motors can operate more reliably in hotter ambient environments without derating or premature failure.

Because a motor built with Sino's high-quality motor laminations wastes less energy as heat, engineers can often coax more power out of a given motor size. Alternatively, they can design a smaller, lighter motor to deliver the same power output.

Excessive heat can cause the magnetic properties of the core material to degrade over time, leading to a gradual decline in motor performance. By keeping things cooler, Sino’s motor laminations contribute to more stable and predictable motor operation throughout its service life.

At Sino, we understand that “one size fits all” rarely works in the world of advanced motor design. That’s why we’ve built our capabilities around not just producing high-quality motor laminations, but also around providing tailored solutions.

We employ a range of manufacturing techniques to create the perfect motor core lamination for your scenario:

1

Precision stamping is the main way to make motor core laminations in large numbers, especially for car EV motors and industrial motors.

For high-volume production, our precision stamping presses create laminations with tight tolerances and excellent repeatability.

Our modern precision stamping can hit tight tolerances of ±10–20 microns for thin electrical steels (0.2–0.5 mm), making sure every part is the same and of high quality.

2

Laser cutting gives amazing flexibility and precision, making it perfect for making prototypes, for R&D, and for small-batch production of complex lamination shapes.

When you need prototypes, complex geometries, or smaller batches, our advanced laser cutting systems offer incredible flexibility and precision without the need for expensive tooling.

Laser cutting usually has tolerances of ±30–50 microns, and we can make it better with advanced fiber lasers and by adjusting the process.

3

This critical heat treatment process, performed in controlled atmosphere furnaces, relieves stresses induced during stamping or cutting and optimizes the magnetic properties of the electrical steel. Sino’s annealing cycles are meticulously controlled for each material grade.

4

We offer various methods to join the individual motor laminations into a robust and dimensionally stable motor lamination stack, including interlocking (creating small mechanical joins between laminations), laser welding along the outer diameter, or bonding with specialized adhesives. The choice depends on the motor’s operational demands and design.

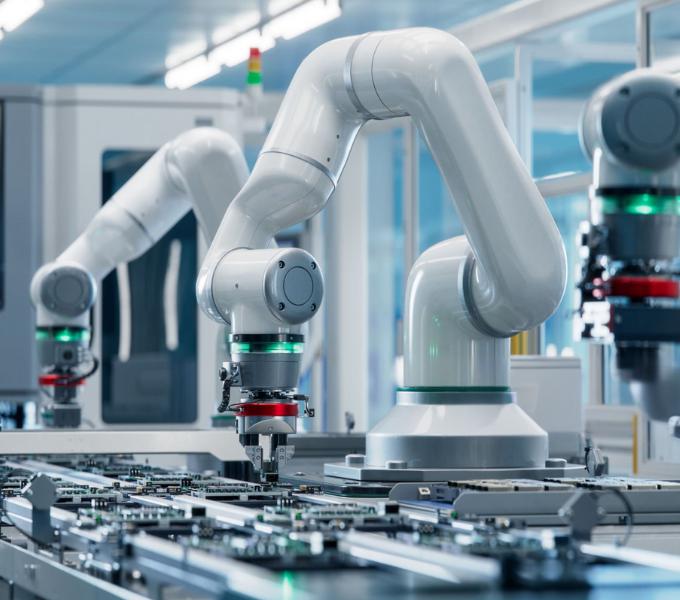

Sino runs fully automated stacking and bonding lines. These include camera-guided robots placing laminations, in-line glue dispensing, and real-time quality checks (like ultrasonic bond inspection). We use digital twins and AI-driven process improvements to reduce cycle time and get the most out of our production, achieving high Overall Equipment Effectiveness (OEE).

Good heat management is extremely important for high-power-density motors. It prevents local overheating and ensures they last a long time. Sino builds top-of-the-line heat management methods directly into the lamination design:

By carefully improving lamination design and adding advanced heat management methods, we make sure that our motor cores deliver unmatched performance and reliability in the most challenging uses.

Do you have a specific slot design? A unique pole count? Are you targeting an unprecedented efficiency level? Bring it on. Our engineering team thrives on collaboration. We work closely with our clients to understand their specific performance targets, operating conditions, and assembly requirements. We can advise on material selection, lamination thickness, insulation types, and stacking methods to create a motor lamination stack that is perfectly optimized for your motor.

From incoming raw material inspection to final dimensional checks on the finished motor lamination stack, quality is embedded in Sino’s DNA. We utilize advanced metrology equipment and rigorous process controls to ensure that every lamination and every stack meets or exceeds your specifications. This meticulous attention to detail is what ensures the consistent performance our customers have come to expect.

In an electric vehicle, every ounce of battery power is precious. High-efficiency motors, built with top-tier motor core lamination stacks, mean more miles per charge. Sino's laminations contribute to making EVs a more practical and appealing option for drivers everywhere by maximizing range.

A factory floor packed with robotic arms working 24/7. If those motors overheat, production stops. Sino’s motor laminations help these critical components run cooler, ensuring higher uptime and productivity. A single line stoppage can cost thousands, so reliability here is paramount.

You want a cordless drill to be powerful but also lightweight and comfortable to hold. Or consider a modern, sleek washing machine that needs to fit into a tight space but still have a powerful motor for spinning heavy loads. Improved power density, facilitated by excellent motor lamination stack design, makes this possible.

By choosing Sino as your partner for motor laminations, motor core lamination components, and complete motor lamination stack assemblies, you’re choosing:

The world runs on electric motors, and those motors run best with precision-engineered laminations. Let Sino provide the core of your success.

Ready to power up your next motor project? Contact Sino today, and let’s discuss how our advanced steel lamination solutions can bring your designs to life!

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.