Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

The motor core is the real center of any electric motor or generator, the quiet partner that controls how well it works, its power, and how long it lasts. In this article, I will explain the world of the motor core in detail. We’ll look at what it is, how it works, and why its design is so important in everything from the smallest household appliance to the most advanced electric vehicles. If you’ve ever wondered how an electric motor works, or if you’re an engineer wanting to improve your next design, this article is for you. I’ll explain the complicated parts in simple ways, using my own experiences and the newest motor technology.

In my time looking at the inside of machines, I’ve learned that the motor core is basically the frame and blood flow system of an electric motor combined. It’s a collection of metal sheets, called laminations, that create the main structure of an electric motor or generator. This core is the base for all other important parts like rotors, stators, windings, and cases. The main job of the motor core is to offer a clear path for the magnetic flux. When electricity flows through the motor’s windings, it makes a magnetic field, and the motor core’s job is to guide this flow well between the part that stays still (the stator) and the part that spins (the rotor). A good path for this magnetic flux is very important for performance; without it, the magnetic system would lose power and not work as well.

Besides its magnetic jobs, the motor core gives very important structural support. It holds the inside parts of the motor, like the rotor and stator, in place, stopping them from breaking down due to shaking or the stress of working. This strong structure is what makes sure the motor runs smoothly and dependably in different situations. Think of it like a car’s strong frame – without it, the engine and wheels would have no solid base to work from. So, the motor core has two jobs: it is the center of the magnetic flow and the backbone that gives it strength. The quality of a motor or generator depends a lot on the quality of its motor core, which needs to be strong, solid, and provide electrical insulation to handle the high pressures and heat inside the machine.

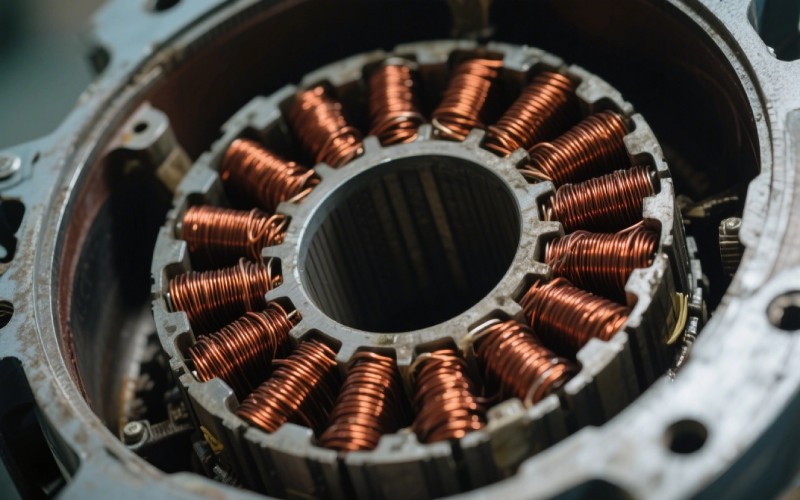

I’ve often found that smart engineering is in the small details. Motor lamination is a great example. Instead of a solid metal block, the motor core is made of thin sheets of electrical steel, usually silicon steel, that are stacked and stuck together. This method is called motor lamination, and it’s a key part of how modern electric motors and generators are designed. The main reason for building it in layers is to fight a problem called eddy currents. When a magnetic field changes inside a metal part, it creates small, circular electrical currents—these are eddy currents. In a solid motor core, these currents would move around without restriction, creating a lot of heat and wasting a huge amount of energy.

By using thin, insulated layers, or laminations, the path for these eddy currents is blocked, greatly lowering their ability to flow. Each lamination has an insulating coat to stop these currents from flowing between layers. This simple-looking new idea has a huge effect on the motor’s efficiency. It cuts down on energy wasted as heat, which in turn makes the motor’s performance better. A well-made set of laminations lets the motor produce more torque with the same amount of power. The process of stamping or laser-cutting these laminations needs to be very exact to make sure they stack together perfectly, making a solid and effective motor core. This careful assembly not only makes it more efficient but also helps lower noise and shaking when it runs.

When I take an electric motor apart, I find a few main parts working together. In its simplest form, an electric motor has a rotor (the spinning part), a stator (the part that stays still), bearings to hold the rotor’s shaft, and windings (the coils of wire). The motor core itself has two main sections: the stator core and the rotor core. The stator core is the non-moving part that holds the windings. When an alternating current goes through these windings, it creates a spinning magnetic field. This field then works with the rotor, creating torque and making it spin.

The rotor is the moving part of the motor, and its core can be built in different ways based on the motor type. For example, in induction motors, you’ll often see a “squirrel cage” rotor core, while other motors might have permanent magnets or their own windings. The rotor core lamination must be strong enough to handle the forces from spinning at high speed while keeping a strong magnetic response. Lead wires are used to bring electrical power to the motor. Lastly, an insulator material is very important to stop electrical current from going where it shouldn’t. All these parts, built on the motor core foundation, work together to change electrical energy into the motion that powers so many things in our lives.

From what I’ve seen, a big part of how efficient an electric motor is, or isn’t, comes directly from its motor core. The design and material of the motor core are extremely important in deciding how well an electric motor changes electrical energy into motion. A high-efficiency motor core is one that lowers energy waste, which mostly happens in two ways: hysteresis losses and eddy current losses. As I said before, making the core from laminations is a key way to lower eddy current losses. The thickness of these silicon steel laminations is a key point; thinner laminations work better at cutting down these losses.

The material of the motor core itself is also a big reason for its efficiency. Electrical steel, an iron mix with a little silicon, is a common choice because of its magnetic qualities. The silicon in it increases the material’s resistance to electricity, which helps lower eddy currents, and it also has low hysteresis losses. The aim is to use a material with high magnetic permeability, which lets strong magnetic fields be made with less energy. In the end, a better motor core design leads to a more efficient electric motor. Since electric motors use a huge amount of the world’s electricity, even small gains in motor efficiency can lead to big energy savings and a greener future. A well-designed motor core not only improves efficiency but also lets a motor create more torque in a smaller size, which is very important in uses like electric vehicles and robots.

I often see the stator as the strong, non-moving center of an electric motor. The stator is the fixed part of the motor, and its main job is to create a spinning magnetic field. It is made of the stator core, windings, and the motor case. The stator core, which is usually made of stacked silicon steel laminations, gives support to the windings and makes a good path for the magnetic field. When an alternating current flows through the stator windings, it creates a magnetic field that spins around the stator.

This spinning magnetic field is what powers the motor. It connects with the rotor, creating a current and its own magnetic field, which then makes the torque that causes the rotor to spin. The design of the stator core is key for the motor’s performance. The slots in the core are made to hold and protect the windings. A well-designed stator core improves the magnetic flux, which increases torque and efficiency while lowering energy waste. The stator basically prepares everything for the whole operation of the electric motor, and its efficiency is a main factor in the motor’s total performance.

I’m always amazed by how widespread electric motors, and therefore, motor cores, are. They are the quiet workers in tons of uses across many different industries. In our houses, you’ll find motor cores in appliances like washing machines, dryers, vacuum cleaners, and other small electronics. In these household uses, the motor laminations must handle high heat and shaking while working well. The quality of the motor core has a direct effect on how long these everyday machines last and how reliable they are.

In the industrial world, the uses for motor cores are even wider. They are key parts in motors that run conveyor belts, robot arms used for building and welding, and automatic machines for jobs like packing and sorting. The exactness and reliability of these industrial motors, which often run all the time, depend a lot on the quality of their motor cores. Also, motor cores are at the center of the growing electric vehicle (EV) industry. In EVs, motor cores must be light, small, and work very well to give the car the best range and performance. From powering our homes to moving our cars and automating our factories, the simple motor core is a truly necessary piece of modern technology.

As I’ve looked into new manufacturing methods, self-bonding technology for motor laminations is a big step forward. In the past, the single laminations in a motor core stack were connected using methods like welding or riveting. Though they worked, these methods can have problems. Welding, for instance, can create a path for eddy currents at the weld spots, which increases waste and lowers efficiency.

Then came self-bonding technology, also called “backlack.” This game-changing process includes covering the electrical steel laminations with a special glue that works with heat. During the making process, after the laminations are cut and stacked, the whole core is heated. This heat turns on the glue, sticking the laminations together into one solid stack. This method has a few benefits over older ways. It removes the need for welding or locking parts together, which can improve the magnetic qualities of the motor core and lead to a more even magnetic field. The result is a motor with lower core losses, better efficiency, and possibly less noise and shaking. This new idea in core making shows the constant effort to improve every part of the electric motor for better performance.

I’ve learned that to really understand motor efficiency, you need to understand the different ways energy is lost. One of the main reasons for this is hysteresis loss. This type of loss happens inside the magnetic material of the motor core itself. As the alternating current moves through the stator windings, the magnetic field in the core is always changing direction. This makes the magnetic parts inside the material line up and un-line up over and over again. This process isn’t perfect; it uses energy, and some of that energy is lost as heat. This is hysteresis loss.

The amount of hysteresis loss depends on the qualities of the core material. Materials that can be easily magnetized and demagnetized are better for lowering these losses. This is another reason why silicon steel is a common choice for motor cores, as it has fairly low hysteresis loss. Even though people talk more about eddy current losses, hysteresis losses are a very important factor in the total efficiency of an electric motor, especially in uses with high frequency. Lowering both types of core loss is a main goal in modern motor design, which leads to motors that work better and run cooler.

I believe the idea of flux paths is basic to understanding how motors and generators are designed. The motor core’s main job is to give a low-resistance path for the magnetic flux. You can think of it as a smooth road for magnetic energy. The design of the motor core, including the shape of the laminations and the slots for the windings, is all about making the best flux paths possible. A good flux path focuses the magnetic field, making the motor work better and letting it create more torque.

The shape of the stator and rotor cores is carefully planned to guide the magnetic flux in a way that gets the most interaction between the two parts. Any problems or weak spots in the flux paths can cause “flux leakage,” where the magnetic field wanders off its planned course, lowering the motor’s performance. The design of these flux paths also has a big effect on other motor features, like cogging torque (the jerky movement at low speeds) and noise levels. Because of this, a lot of engineering work is put into planning and improving these flux paths to make a smooth, efficient, and powerful electric motor or generator.

Looking to the future, I see an exciting and game-changing trend for electric motors and car technology. The constant push for better efficiency and more power in a smaller size is stretching the limits of motor core design and materials. In the car industry, especially with more electric vehicles, the need for advanced motor core technologies is growing fast. We’re seeing a shift to even thinner electrical steel laminations and the study of new materials like amorphous alloys and soft magnetic composites (SMCs). These advanced materials promise even lower core losses and better performance at high frequencies.

Also, new developments in making things, like high-speed laser cutting and exact stamping, are allowing for more complex and better motor core shapes. This makes it possible to create designs that couldn’t be made before, leading to motors that are smaller, lighter, and stronger. Adding advanced cooling systems inside the motor core itself is another key trend, helping to control the heat made in high-performance uses. As technology keeps moving forward, I expect to see even more new ideas in motor core technology, leading to a new wave of highly efficient and powerful electric motors that will lead the change in transportation and factory automation.