Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

One huge energy eater I frequently discover is core loss. A big component of this is hysteresis loss. It can really hurt just how well an induction motor works. This loss transforms useful electrical energy into thrown away warmth.

In this message, I want to share what I’ve discovered about this difficult hysteresis loss. We’ll look at the old, relied on methods to eliminate it, like making use of steel lamination in the motor core. After that, we’ll explore more recent ideas, like soft magnetic composite (SMC) materials. Is SMC vs steel lamination a clear choice? You’ll figure out which may be much better for your motor layout. A lot more significantly, you’ll see why this matters for saving energy and structure far better electric equipment. This short article is worth your time if you intend to genuinely comprehend motor effectiveness and the materials that make it possible.

Consider it similar to this. The magnetic material inside an induction motor needs to switch its magnetic direction very fast. This takes place lots of, oftentimes a second. This quick switching makes the stator and rotor work together to spin the motor. However this switching isn’t completely smooth or very easy for the magnetic material. The material withstands this adjustment a bit. This resistance, this “magnetic friction,” creates heat. That warmth is wasted power. We call this specific power waste hysteresis loss. It’s a vital part of what we call iron loss in any kind of electric machine.

A huge factor was this hysteresis loss. The magnetic material in the stator core just couldn’t stay up to date with the quick magnetic changes without a fight. This battle, this lag in reacting, is “hysteresis.” It occurs in the magnetic component of the motor. The more the magnetic flux density changes to and fro, the a lot more hysteresis loss you may see. Making good electric motors implies discovering means to cut this loss down.

Yes, core loss is a huge bargain for any type of motor! Hysteresis loss is one component of it, as we just talked about. The other huge component is something called eddy current loss. When you put these 2 together– hysteresis and eddy current losses– they compose the total core loss. You could also hear this called iron loss. This loss happens in the iron components of the motor, like the stator core and sometimes the rotor. It turns excellent electric power into warm, not helpful rotating work. So, a motor with high core loss is not a reliable motor.

In some, core loss can consume a big piece of the power pie. This indicates you wind up paying a lot more for electricity to get the same task done. The motor likewise obtains hotter because of this squandered energy. A hotter motor can have a much shorter life. Or, it may indicate you need bigger, a lot more pricey cooling systems. So, finding methods to decrease core loss is incredibly essential for any individual making or making use of an electrical machine. This is specifically real when you’re going for high-efficiency in your motor effectiveness objectives.

We make use of lamination in a motor primarily to fight that component of core loss: eddy current loss. Think of if the stator of a motor was made from a solid chunk of iron. When the electromagnetic field inside the motor adjustments (which it does constantly when it’s running), it creates eddy currents inside that solid iron. These are the eddy currents. Think about them as little whirlpools of electrical power. They do not do any beneficial work. They just spin around inside the iron, making warmth. Lamination is a creative technique to stop these.

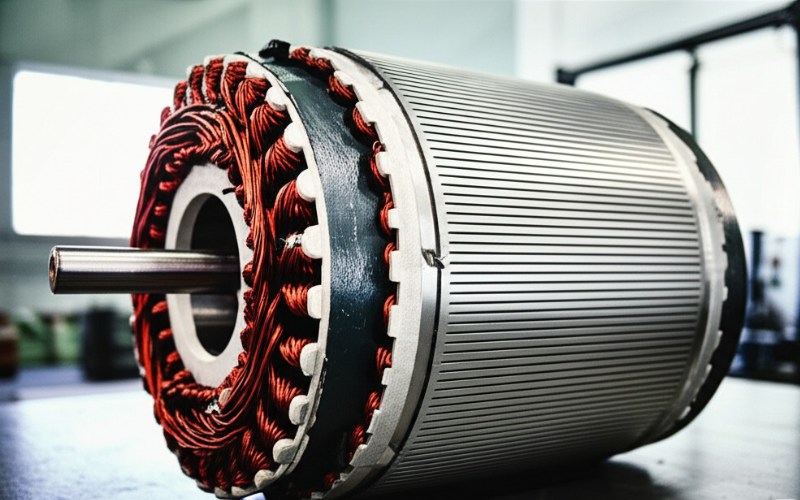

A lamination is just an extremely thin sheet of electric steel. To make a stator core, we stack many of these thin sheets together. Most importantly, there’s a tiny bit of insulation in between each sheet of lamination. This insulation separates the courses for those large, inefficient eddy currents. So, rather than big whirlpools of present creating lots of eddy current loss, you get much, much tinier ones. These small ones cause far less difficulty and much reduced eddy current heat. This is an extremely common way to build the stator in numerous electric motors. The style of the lamination itself is key to exactly how well this works.

Conventional steel lamination is pretty good at cutting down eddy current loss in an induction motor. By using thin sheets of special electrical steel, we make it really hard for those big eddy currents to stream. This is a big win for reducing one component of core loss. For the hysteresis loss part, the sort of electrical steel utilized for the lamination actually matters. Some steels are made so their tiny magnetic domains can flip direction extra quickly. This indicates much less resistance, therefore, much less hysteresis loss.

Yet, lamination isn’t the perfect solution for all core loss. There’s still some hysteresis loss in the electrical steel itself, regardless of exactly how good it is. And, if the laminations aren’t completely protected from each other, or if they get damaged coax assembly, eddy currents can still find paths to flow and cause troubles. Likewise, a huge aspect of lamination is that it makes the magnetic flux (the magnetic power) wish to travel mostly along the level airplane of the lamination sheets. This can restrict some motor layouts, especially if you need complex magnetic flux paths that go in all directions. These laminated steel cores prevail in several devicesRIM today.

Now, let’s discuss Soft Magnetic Composites, or SMCs. These are a newer type of magnetic material for motors. They are fairly different from the conventional laminated steel sheets we just went over. Imagine SMC materials as being constructed from zillions of tiny iron particles. Every one of these tiny iron particles is coated with a super, super slim layer of electric insulation. After that, all these layered bits are pressed together extremely, very tightly. They are pushed into a mold and mildew to créate a strong shape, like a stator core for a motor. This process helps achieve a good density.

Individuals were very thrilled about the possibilities. Since each small bit is shielded from its neighbors, SMCs are naturally fantastic at stopping those eddy currents. The eddy current loss can be really low in an SMC core, especially when the motor is running at high speeds or high frequencies. This opens up brand-new doors for motor layouts, especially for a progressed motor that requires it to work in a different way than older ones. These composite materials use brand-new means to think of how a magnetic component of an electrical machine is made. The application of SMC is growing.

SMC materials manage hysteresis loss in an induction motor in a few ways, and it’s a little different. The iron particles made use of to make soft magnetic composite (SMC) are chosen to be “soft” magnetically. This indicates their interior magnetic direction can flip back and forth a lot more easily. When it’s much easier to flip, you get reduced hysteresis loss. That’s the excellent part. Nonetheless, the procedure of making SMCs involves pushing these particles along with a lot of pressure. This pushing can often add a little stress and anxiety to the tiny particles. This stress can, regrettably, boost hysteresis loss a little bit.

So, when it pertains to hysteresis loss, it’s often a trade-off with SMC materials. The very small bit dimension and the insulation are excellent for lowering total iron loss, especially the eddy current loss component. But, the density of an SMC core is generally a bit less than a core made from strong electrical steel laminations. This lower density can suggest that the magnetic performance isn’t as strong. You may need a bit more SMC material to carry the very same amount of magnetic power. This can indirectly impact the hysteresis loss image. An optimal design for the motor has to stabilize these factors. Designers commonly make use of computer tools like FEA (Finite Element Analysis) to research this and optimize the magnetic material choice.

When we do a direct contrast between SMC vs steel lamination for induction motors, things obtain very fascinating. For numerous basic induction motors that perform at rather low frequencies (like the 50 or 60 times per second from your wall surface outlet), good old electrical steel lamination usually comes out in advance when we just check out hysteresis loss. The special electrical steel made use of in lamination is extremely refined and processed to have very low hysteresis loss at these speeds. SMCs, on the other hand, have a tendency to reveal their biggest advantages when the operating regularities are greater. This is since their superpower is considerably cutting down eddy current loss, which becomes a substantial trouble at high speeds.

So, the very best selection in this comparison truly depends upon the particular induction motor and just how it’s utilized. In several typical induction kinds of electric motors, the magnetic fields in the stator change at what we call line frequency. At these fairly reduced speeds, the hysteresis loss part of the complete core loss can be a lot more considerable than eddy current loss, specifically if the laminated steel core is well-made. In these cases, the soft magnetic composite material could actually show a little bit higher hysteresis loss. But also for some special induction motor designs, or for electric motors that need to rotate extremely, really fast, SMCs could be the victor. Often, a technical paper provides a comprehensive comparative evaluation for particular makers by doing this.

This is the huge inquiry everyone asks: can SMC material minimize overall core loss greater than laminated steel in a motor? The truthful solution is: “it depends.” Soft magnetic composite (SMC) is definitely outstanding at slashing eddy current loss. If your motor layout is one where eddy current loss is the primary bad guy causing difficulty, after that using an SMC core can result in much lower total core loss. This is frequently the situation for high-speed electric motors, or for electric motors that have very complex, three-dimensional (3D) magnetic flux paths. These are courses where it’s difficult and even difficult to make use of typical level lamination sheets efficiently.

Nonetheless, if hysteresis loss is the bigger component of your core loss problem (which can happen in lower-speed motors), after that state-of-the-art electrical steel lamination could still be the much better option for lower iron loss. One more thing to keep in mind is that the density of SMC is normally less than strong steel lamination. This can mean its magnetic performance (just how much magnetic power it can handle for its dimension) is a bit reduced, unless the motor is carefully developed for it. So, you can not normally just swap out a laminated steel stator core for an SMC core and anticipate magic. You are required to maximize the entire motor layout– including the stator and rotor — for the certain magnetic material you select. Making use of simulation results from finite element analysis (FEA) is crucial below.

Yes, like any kind of product, there are some points to keep an eye out for if you’re considering using soft magnetic composite (SMC) in an induction motor core. One crucial factor is that SMC products commonly have a reduced saturation value for magnetic flux density contrasted to premium electrical steel. This implies it can not carry fairly as much magnetic “power” in the same quantity of space prior to it obtaining “complete.” If you don’t account for this in your style and optimization, it could indicate the motor needs to be a bit bigger or it may not be as powerful. The mechanical toughness of SMCs can also be lower than strong steel, which can matter in some motor applications.

An additional thing to take into consideration is the cost and how you make the parts. While SMCs enable really trendy and complex 3D shapes for the stator core — which can be a big plus for certain motor topology like an Axial Flux Permanent Magnet (AFPM) machine or designs aiming for minimization of torque ripple — the SMC product itself and the manufacturing procedure to make the SMC core might be a lot more expensive for some sorts of electric motors or manufacturing quantities. The lower density additionally means you might require a bit more SMC material by weight or volume to do the very same magnetic task as much less iron in a steel stator. You are required to think of the entire layout and manufacturing procedure. The reliability of these new materials and making strategies is likewise an ongoing location of study for the efficiency of SMC.

First, if you are making high-efficiency, high-speed electrical motors, SMCs are a very strong challenger. Their ability to keep eddy current loss incredibly reduced at high frequencies is an enormous benefit there. This helps boost motor performance. Second, if your motor style requires challenging 3D magnetic flux paths — shapes that are truly tough or cumbersome to make with flat steel lamination — after that the application of SMC is a terrific idea. This is often the case in some types of Axial Flux Permanent Magnet (AFPM) machines, Flux-Switching Permanent Magnet (FSPM) machine designs, or specialized concepts like yokeless and fractional-slot motors. SMC motors can allow these unique topology options.

Also, if you are discovering innovative manufacturing like additive production for your magnetic component, then SMC-like composite materials could be a large component of that future. For sure permanent magnet synchronous motor layouts, or even a permanent magnet brushless dc motor, where you want to truly maximize for things like extremely low cogging torque or smooth output torque (reduced torque ripple), SMCs provide engineers brand-new design freedom for the stator. Constantly, constantly use powerful computer system devices like finite element analysis (FEA) to run a relative evaluation based on your certain layout parameters. Think of the total device performance,DUC thermal analysis, power factor, and its influence on the effectiveness of the motor. It has to do with finding the optimum option for different applications, possibly also for an electrical lorry where high torque density and reliability are vital. This research aims to aid you make that choice. The results show that careful design and optimization are crucial.