Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

You may ask yourself just how an electric motor can be so effective and smooth. A huge key is inside, in its core, made of several thin steel lamination sheets. This short article will certainly show you just how these motor lamination stacks are made using modern die stamping. It’s worth reading due to the fact that comprehending this lamination manufacturing helps you see why some motors are better than others. We’ll check out the manufacturing process for these crucial lamination parts.

A motor lamination is a very thin slice of special steel. Think of it like a solitary sheet of paper, yet constructed from steel. A lot of these lamination sheets are piled with each other to make a component called a core. This core is a vital part of an electrical motor. The word lamination itself implies a thin layer. So, a motor lamination is just one thin layer utilized to develop the motor core.

When we make an electric motor, we require several, many of these lamination pieces. Each lamination is cut very carefully. The form of the lamination is extremely crucial for how the motor will certainly function. This careful cutting and shaping is a huge component of lamination manufacturing. We make sure each and every single lamination fulfills the appropriate specifications.

The idea of making use of a lamination is to make the motor more efficient. If the core was one solid item of metal, it would certainly have problems. Using thin lamination sheets helps stop these troubles. This is why the motor core lamination process is so critical for an excellent electric motor. Each lamination plays a role.

We need lamination in an electrical motor core primarily to fight something called eddy currents. When a motor runs, it creates a changing electromagnetic field. If the motor core was a strong block of steel, this magnetic field would certainly make small, swirling electric currents inside the core. These are eddy current flows.

These eddy current flows are bad information. They throw away energy by turning it into heat. This makes the motor less effective and can also make it get too hot. By using thin lamination sheets, we separate the path for these eddy currents. Each lamination is frequently covered with a slim insulation layer. This layer stops the eddy current from jumping from one lamination to the following.

So, the major work of each lamination is to reduce eddy current losses. These aids make an efficient motor. The thinner the lamination, the much better it goes to stopping these eddy currents. This is a crucial reason why the lamination technique is made use of in practically every common motor and transformer. It’s everything about lowering power losses.

For motor stator laminations, we typically utilize a special kind of steel called silicon steel. Sometimes it’s also called electrical steel. This isn’t just any kind of steel. It has a little bit of silicon added to it. The silicon transforms the steel’s magnetic properties in a great way.

This silicon steel is fantastic for carrying magnetic flux, which is what a motor needs to function. It also helps in reducing core loss, which is power wasted in the core. The lamination made from this steel assists the magnetic field do its job without losing way too much power. There are different sorts of silicon steel, like CRGO (Cold Rolled Grain Oriented) steel, which is typically made use of in a transformer. For a motor lamination, we pick the steel that fits the design requirements.

The choice of material for the lamination is very important. It influences the motor performance and just how reliable the electric motor will be. Using high-grade silicon steel for each lamination makes sure the motor will be resilient and efficient. The manufacturing process should handle this unique steel carefully.

Lamination stamping is exactly how we cut out each lamination from a larger steel sheet or coil of electrical steel. Imagine a really specific cookie cutter, but for steel. This “cookie cutter” is called a tool or a die. An effective machine, a press, pushes this tool through the steel sheets to produce the exact form of the lamination.

This procedure includes a great deal of force and precision. The die should be extremely sharp and solid to make clean cuts. Each lamination needs to be specifically the appropriate size and shape, within a very tight tolerance. If the lamination stamping isn’t perfect, the motor lamination stacks will not fit together correctly, and the motor won’t function as well.

The stamping component of lamination production can make many lamination pieces swiftly. This is important for high-volume production. The quality of the die and the machine doing the stamping straight influences the top quality of the final lamination. This is a core action in motor lamination manufacturing.

Progressive die stamping is an extremely smart means to make a lamination. As opposed to one large die doing every little thing at the same time, a progressive die has lots of steps, or stations. The steel sheet, typically from a coil, moves through the machine one action at once. At each step, a different component of the die does a tiny amount of work on the lamination.

As an example, the primary step may punch some tiny holes. The next step could cut components of the outside form. One more step might produce slots for the motor’s windings. The lamination is slowly formed as it “progresses” with the die. At the very last step, the finished lamination is cut from the metal strip.

This method is wonderful due to the fact that it’s extremely quick and effective for making great deals of identical lamination components. Progressive die stamping is excellent for cost-efficient manufacturing of motor lamination components. It helps make sure each lamination is premium quality and satisfies the design requirements for the stator or rotor.

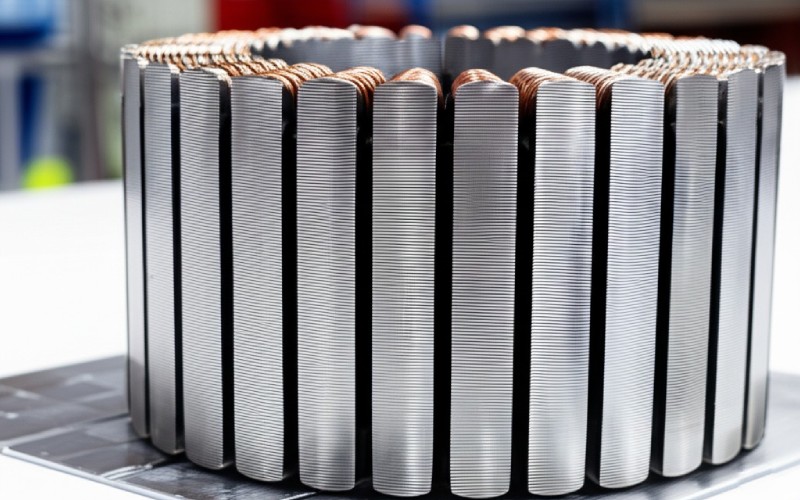

Once we have all the private lamination pieces from the stamping process, they require to be assembled. This is called stacking. We take many motor lamination sheets and stack them up, one on top of the other, to form the stator core or rotor core. The variety of lamination sheets in a stack depends on the motor design.

During stacking, it’s important that the lamination sheets are lined up perfectly. Sometimes, they are held with each other by a bond along the outdoors, or by interlocking attributes that were stamped into the lamination itself. Another way is to weld them, interlock them, or use a special bonding adhesive. The objective is to make a solid core that still maintains the electrical insulation in between each lamination.

This assembly creates the motor lamination stacks that become the heart of the stator or rotor. The stator core is the fixed component of the electric motor, and the rotor is the component that spins. Both typically utilize these laminated cores to enhance performance and efficiency.

The quality of lamination manufacturing is incredibly essential since the motor core directly affects motor efficiency. If the lamination sheets are not made right, the electrical motor won’t be an efficient motor. Poor quality can imply extra eddy current losses, a lot more heat, and a much shorter life for the motor.

Think of the tolerance required for each motor lamination. If they are thick, thin, or the wrong form, the stack will not be right. This can alter the magnetic properties of the core. Even little mistakes in the stamping process or the insulation coating can trigger large problems. High-quality lamination manufacturing ensures that the motor functions as designed, offering excellent performance and durability.

This is why businesses purchase great tool designs, accurate tooling, and careful top quality checks throughout the production process. From picking the best electrical steel to the last assembly of the stator core, every action in stator lamination manufacturing matters. This isōn especially true for demanding applications like electric cars or industrial machinery.

The process of motor lamination has several key steps. Initially, we pick the right product, typically silicon steel, based on the motor’s design specifications. After that, this steel (usually in a coil) is fed into a stamping press. This is where the lamination stamping occurs, cutting out the individual motor stator laminations or rotor components.

After stamping, the lamination parts may experience a deburring process to eliminate any type of sharp sides. After that, if not currently covered, an insulation layer could be used. Following is stacking. The lamination sheets are stacked to form the core. This stack can be held together by weld points, interlocking, or bonding.

Ultimately, the stator core or rotor core is looked for top quality. This guarantees it meets all the required specifications. This careful manufacturing process assists in making motor components that are efficient and trustworthy. The whole motor lamination manufacturing sequence is made to enhance motor performance and decrease core loss.

In the majority of electric motor styles, there are two main parts that make use of lamination technology: the stator and the rotor. The stator is the part that stays still. The rotor is the part that revolves or rotates. Both the stator and rotor need a core made from steel laminations to manage the magnetic fields appropriately.

Stator laminations are piled with each other to create the stator core. This core typically has slots where copper wires (windings or coils) are wound. When electrical energy streams via these wires, it develops an electromagnetic field. The stator lamination manufacturing focuses on producing a core that directs this area efficiently.

The rotor likewise has a core made from a stack of lamination items. These are called rotor laminations. The rotor core interacts with the magnetic field from the stator, triggering the rotor to turn. Similar to stator laminations, rotor laminations are created to lower eddy current and improve the motor’s total performance. So, both stator and rotor laminations are vital parts.

An excellent motor lamination stack has several essential functions. First, it uses high-quality silicon steel or one more suitable alloy for its lamination layers, selected for its magnetic properties. Each lamination should be precisely cut, with clean sides and the proper form, meeting tight tolerance requirements. This guarantees they fit together perfectly in the stack.

The insulation between each lamination is also crucial. It must be slim yet effective at stopping eddy current from moving between layers. This means the stack is held with each other– whether by welding, interlocks, or bonding– ought to be solid yet not harm the lamination or short-circuit the insulation. A reliable stack causes low core loss and assists in developing a reliable and cost-efficient electrical motor.

Eventually, a good motor lamination stack enables the motor to perform at its finest, supplying the required power while reducing energy losses. This is essential for a wide range of applications, from home devices to huge commercial equipment and also electrical lorries. Good lamination manufacturing and assembly make these laminated cores flexible and suitable for various sectors, boosting total performance. The role in enhancing motor efficiency can not be overstated.