Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

The number of poles in a motor is one of its most important features. It decides the motor’s speed and torque. This article will make it simple for you. We will look at what a motor pole is, what the number of poles of the motor mean, and how to pick the right motor for your needs. This is worth reading because understanding the number of poles will help you choose a better, more efficient motor for any project.

Let’s start with the basics. Think of a simple bar magnet. It has a north pole and a south pole. A motor pole is very similar. It is a magnetic pole created inside an electric motor. These poles are what make the motor spin. Every motor has an even number of poles, because for every north pole, there must be a matching south pole. You will never find a motor with 3 or 5 poles. The most common pole numbers you will see include 2 poles, 4 poles, 6 poles, or 8 poles.

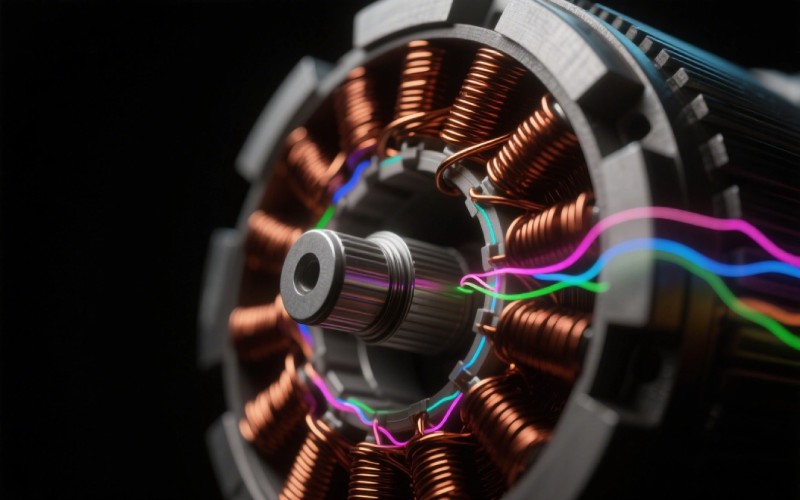

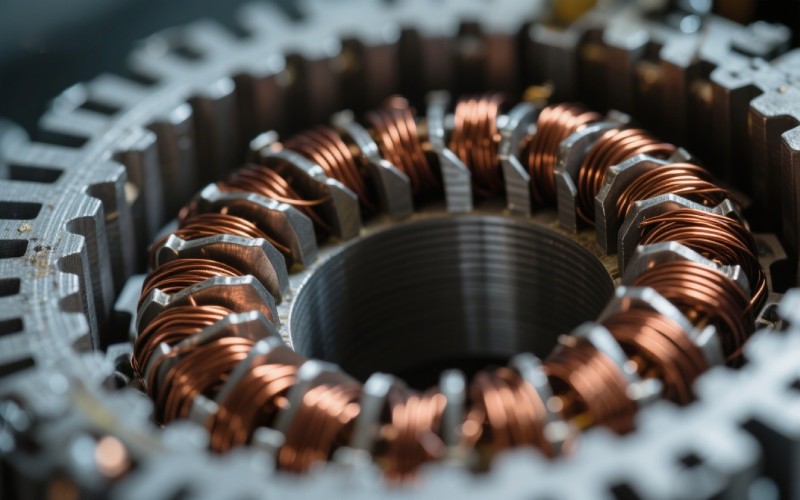

These magnetic poles are not made from permanent magnets in most AC motor designs. Instead, they are created by electricity. Inside the motor’s stationary part, called the stator, there are slots with copper wire. This is the stator winding. When you apply a voltage to this winding, it creates a powerful magnetic field. The way the coil is wound determines the number of poles. A simple winding creates two poles (one positive, one negative pole at any instant), while a more complex winding can create four, six, or more poles. The number of poles is a fixed feature of a motor.

So, how do these poles make a motor rotate? The magic happens because of a changing magnetic field. The stator winding is designed so that when AC voltage is applied, it creates a magnetic field that spins around the inside of the motor. The speed of this spinning field is directly tied to the number of poles and the frequency of the electrical power (which is 60 Hz in the U.S.). This spinning field is what we call the synchronous speed.

The moving part of the motor, the rotor, has its own set of magnetic poles (or is made of a material that gets magnetized by the stator’s field). The rotor’s poles are attracted to the spinning poles in the stator. As the stator’s magnetic field changes and rotates, it pulls the rotor along with it, causing the motor shaft to spin. The rate at which the magnetic field changes determines the speed of the motor. A motor with fewer poles has a magnetic field that has to rotate faster to complete a cycle, resulting in a higher motor speed.

The significance of motor pole numbers is pivotal. This single parameter tells you the most important things about how a motor will behave. The pole number is not just a technical detail; it is the key to understanding the motor’s core purpose. When you choose a motor, the number of poles is one of the first things you should look for. It has a direct influence on the motor’s speed, torque, and overall efficiency.

Choosing the wrong pole number can lead to problems. If you pick a motor that is too fast for your machine, you could damage it. If you pick a motor with too little torque, it won’t be able to do the work. The number of poles also affects the physical size of the motor. Generally, a motor with a higher pole count will be larger and heavier than a motor with a lower pole count for the same output power. This is a critical trade-off in many designs, especially when you have to fit a motor within certain volume and weight limits.

Here is the most important rule to remember: the more poles a motor has, the slower it runs. The fewer poles a motor has, the faster it runs. It is a simple, inverse relationship. The highest possible speed for a standard AC motor is achieved with two poles. The speed of the motor is determined by a formula that uses the frequency of the power supply and the number of poles.

The theoretical maximum speed of a motor is called the synchronous speed. This refers to the speed of the rotating magnetic field. For a 60 Hz supply, a 2-pole motor has a synchronous speed of 3600 RPM (revolutions per minute). A 4-pole motor runs at 1800 RPM. A 6-pole motor runs at 1200 RPM. The actual speed of the motor shaft, or its rated speed, will be slightly less than the synchronous speed due to small losses. So, if you need a high-speed motor, you look for one with fewer poles. If you need a motor for lower speeds, you look for one with more poles.

Yes, the difference is huge. A 2-pole motor is all about speed. With a synchronous speed of 3600 RPM, it is the fastest standard motor you can get. These motors are great for applications that need to move air or fluid quickly, like fans, blowers, and some types of pumps. However, this high speed comes at a cost. A 2-pole motor generally produces less starting torque than a motor with more poles. Its output power is high for its size, giving it good speed and power density.

A 4-pole motor, on the other hand, is a great all-around performer. Running at 1800 RPM, it offers a good balance between speed and torque. This makes the 4-pole motor the most common type of electric motor used in a huge range of machines, from a compressor to power tools. It provides more torque than a 2-pole motor of the same size, making it better for starting under load. The choice between a 2-pole and a 4-pole motor depends entirely on whether your application needs higher maximum speed or more turning force (torque).

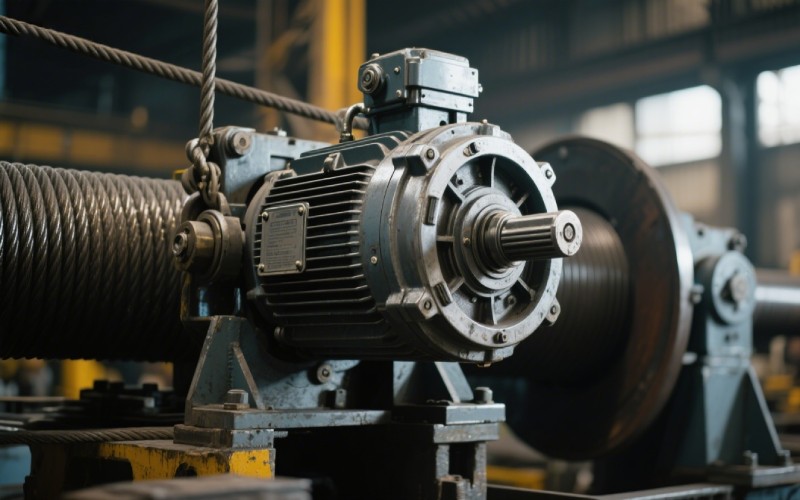

You should look at a 6-pole or 8-pole motor when your application requires low speed and high torque. A 6-pole motor runs at a calm 1200 RPM. This slower speed is perfect for machines that need a steady, powerful motion. You might find a 6-pole motor in some gear pumps, conveyors, and other industrial equipment where high speed is not needed, but strong, consistent torque is. The 6-pole design provides a smoother operation than a faster motor.

Then we have 8-pole motors. These are the slow, powerful workhorses. An 8-pole motor has a synchronous speed of only 900 RPM. If you see a spec that says the 8-pole synchronous speed is 750 RPM, that is for a 50 Hz power supply, common in Europe. These motors are built for heavy-duty tasks. They produce a lot of torque, making them suitable for applications like an elevator, a large crane, or a heavy-duty pump. The higher pole count in 8-pole motors means they are larger and heavier, but they deliver very smooth power with low vibration.

We have talked a lot about torque, but let’s get specific. Torque is the rotational force of the motor. The number of poles has a direct influence on a motor’s torque characteristics. As a general rule, motors with more poles produce higher starting torque. A 4-pole motor will have better starting torque than a 2-pole motor, and an 8-pole motor will have even more. This is because the magnetic field intensity is distributed over more poles, creating a more even and powerful pull on the rotor from a standstill.

Another benefit of a higher pole number is smoother torque delivery. A motor with only two poles has a magnetic field that makes bigger “jumps” as it rotates. This can lead to more torque fluctuations and vibration. A motor with 6 poles or 8 poles has a magnetic field that moves in smaller, more controlled steps. This results in a much smoother output, which is critical for applications requiring precision and low vibration, like a printer or certain medical equipment. This is why an elevator uses a motor with a higher pole count for a smooth, comfortable ride.

Yes, you usually can. The easiest way to find the pole number is to look at the motor’s nameplate. The nameplate is a small metal plate on the side of the motor that contains all the important information. It will list the rated voltage, output power, and, most importantly, the rated speed in RPM.

While the nameplate might not explicitly say “4-pole” or “6-pole,” you can figure it out from the RPM. If you are in a 60 Hz country like the U.S. and the nameplate shows an RPM just under 3600 (like 3450 RPM), you have a 2-pole motor. If the RPM is just under 1800 (like 1725 RPM), it is a 4-pole motor. An RPM near 1200 (like 1140 RPM) means it is a 6-pole motor. This rated speed of a motor is the key to identifying the number of poles.

The different pole numbers are designed for different application scenarios. Each pole number has a job it is best suited for. A 2-pole motor is perfect for high-speed applications. Think of fans, blowers, grinders, and some centrifugal pumps. These are jobs where moving something fast is the main goal. The lower torque of a 2-pole motor is not an issue here.

A 4-pole motor is the jack-of-all-trades. You will find this electric motor everywhere. They are used in most commercial and industrial equipment, including air compressors, lathes, and almost any machine that needs a good balance of speed and power. A 6-pole motor is used for applications requiring lower speeds and more power, like some conveyors and positive displacement pumps. Finally, 8-pole motors are for special, low-speed, high-torque jobs. Think of elevators and rail traction, or heavy-duty crushers. They are also used in washing machines and electric vehicles where variable speed and high torque are needed.

Choosing the right pole number is pivotal for getting the best motor performance. It is about matching the motor to the job. Using the wrong number of poles can lead to an inefficient system that wastes energy and wears out quickly. For example, if you use a fast 2-pole motor for a slow conveyor belt, you will need a complex and expensive gearbox to slow it down. It would be much smarter and more efficient to just use a 6-pole or 8-pole motor from the start.

The correct pole number ensures the motor operates at its best efficiency point. It provides the right amount of torque without strain and delivers the correct speed for the application. This choice affects not just the power of the motor, but also its lifespan. A properly selected motor will run cooler and with less vibration, leading to a longer, more reliable life. So, the next time you look at a motor, pay close attention to that pole number. It tells you more about that motor than almost any other parameter.