Let Sino's Lamination Stacks Empower Your Project!

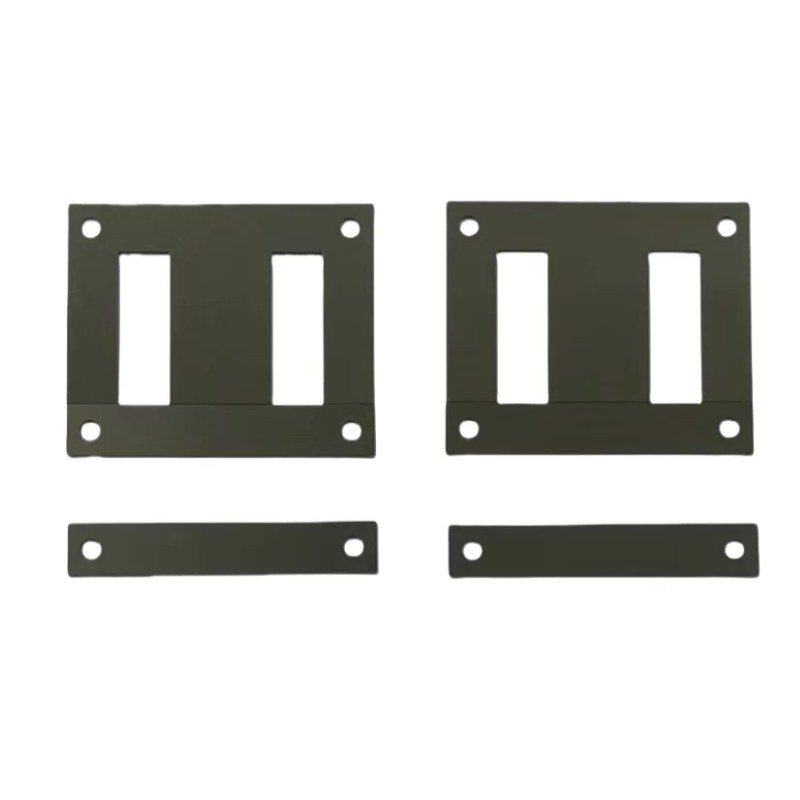

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

At Sino, we focus on the design, making, and selling of high-quality nickel-iron (Ni-Fe) core laminations. They are made to meet the tough needs of motor and transformer makers in different industries around the world. Our dedication to being accurate, using great material science, and modern making methods makes us a partner you can trust for your most important magnetic part needs.

At Sino, our knowledge of material science is the basis for the great performance of our nickel-iron core laminations. We carefully control the natural magnetic and electrical features of our alloys, using the unique metal-making factors that give them their good properties.

We mostly work with high-nickel alloys, similar to the well-known 80% Ni, 20% Fe mixes, and we also offer recipes with about 50% Ni, 50% Fe.

We carefully add small amounts of other elements to adjust the magnetic properties:

Permeability measures how easily a material allows magnetic flux (those invisible lines of magnetic force) to flow through it. And when it comes to nickel-iron alloys, we’re talking exceptionally high permeability. At Sino, we understand that realizing the full potential of these alloys isn’t just about the raw material; it’s about the craftsmanship. Our precision manufacturing and careful annealing processes ensure that the nickel iron core laminations we produce maintain their incredible permeability.

Coercivity is basically the “stickiness” of the magnetism – how much effort it takes to demagnetize the material or flip its magnetic polarity. Hysteresis loss is the energy that gets wasted as heat each time the core is magnetized and demagnetized. Nickel-iron alloys are celebrated for their very low coercivity. This means they’re not magnetically “sticky” at all. They magnetize and demagnetize with incredible ease. At Sino, our meticulous control over alloy composition and heat treatment minimizes this coercivity further, leading to an ultra-narrow hysteresis loop.

Whenever a conductive material (like our core) is exposed to a changing magnetic field, tiny circular currents are induced within the material itself. These are eddy currents. They generate heat, and they can even create their own magnetic fields that oppose the desired field changes, especially as frequencies climb. By stamping or laser-cutting the nickel iron core material into very thin sheets (sometimes just a few thousandths of an inch thick!) and then applying an insulating coating to each one before stacking them, we dramatically increase the electrical resistance in the path of these unwanted currents. We can produce laminations as thin as 0.05mm (0.002 inches) for higher frequency needs, ensuring eddy current losses are squashed. Our precision stacking techniques guarantee optimal alignment and minimal air gaps, maximizing the core’s magnetic performance.

Nickel iron core materials maintain their high permeability and responsiveness even at very low magnetic flux densities. We carefully select and process our nickel-iron alloys to ensure they deliver this outstanding performance when your scenario involves barely-there signals.

Nickel-iron core laminations are the foundation of high-quality magnetic parts, especially when the best magnetic features are most important. These special metal mixes offer a unique combination of high permeability, low core loss, and a very straight-line response. This makes them essential for uses that need exact control over magnetic fields and good energy flow.

Our Ni-Fe laminations are carefully made for many different advanced uses, such as:

Medical devices such as Magnetoencephalography (MEG) systems often rely on rooms shielded with Mu-metal (a high nickel-iron alloy) or components with similar cores to guide and concentrate these minute signals. Sino can supply laminations for the transformers and sensors within such demanding apparatus.

In high-fidelity audio transformers, particularly input and interstage transformers handling delicate signals, nickel-iron cores (such as those with 78-80% nickel) ensure that every nuance of the music is captured and passed on without loss or distortion. The very first stage of an amplifier dealing with a weak signal from a microphone, sensor, or antenna needs a core that doesn't "ignore" the signal. Sino's nickel-iron core laminations ensure maximum signal transfer and minimal noise introduction.

Certain SMPS designs, particularly those requiring exceptional regulation or dealing with complex waveforms, benefit from the stable permeability and controlled losses of laminated nickel-iron cores, even if ferrites are common elsewhere in the circuit.

Made to meet tough rules, our Ni-Fe laminations work dependably in harsh conditions, from -55°C to +125°C, and can handle shaking and shock. Their excellent stability in different temperatures and low eddy current losses at frequencies up to 500 kHz make them perfect for airplane electronics and radar power supplies, where being highly reliable is most important.

For small and energy-saving switch-mode power supplies (SMPS), our thin Ni-Fe laminations (as thin as 0.1 mm) are very important. They usually work from 20 kHz to 200 kHz and greatly lower eddy current losses. This allows for more power in a smaller space and less heat build-up compared to other materials in some designs.

Measuring core loss accurately is very important. We follow international rules and use advanced methods:

At Sino, we’re not just stamping out metal. We’re deeply involved in the science and art of creating high-performance nickel iron core laminations.

We work with alloys like high-purity 78-80% Nickel-Iron (similar to Permalloy 80 or HyMu 80) and other specialized grades, ensuring the foundational material quality.

Whether it's ultra-precise stamping for standard EI, EE, or F shapes, or custom laser-cutting for unique geometries, our manufacturing tolerances are tight. We understand that consistency from lamination to lamination is key.

This heat treatment step is critical for nickel-iron alloys. It relieves stress from machining and grows the grain structure, unlocking that amazing high permeability and low coercivity. Sino’s annealing cycles are carefully controlled and optimized for each alloy and lamination thickness.

The quality of the interlaminar insulation (often an oxide layer or a specialized coating) is crucial for minimizing eddy currents. We ensure robust, consistent insulation.

Off-the-shelf doesn't always cut it. Sino excels at producing custom lamination stacks tailored to your specific dimensions, shapes, thicknesses, and material grades. Need a toroidal core, a C-core, or a complex E-core variation? Let's talk.

To give you a clearer picture, here’s how our high-performance nickel-iron materials generally stack up. (Remember, specific values depend heavily on the exact alloy, heat treatment, and lamination thickness – Sino can provide precise data for your chosen material).

Property | Sino Nickel-Iron (e.g., 80% Ni) | Silicon Steel (Grain-Oriented) | Ferrite (e.g., MnZn) |

Initial Permeability (μi) | Very High (20,000 – 100,000+) | Moderate (1,500 – 5,000) | High (1,000 – 15,000) |

Max Permeability (μmax) | Extremely High (100,000 – 1,000,000+) | High (20,000 – 70,000) | Moderate (3,000 – 20,000) |

Saturation Flux Density (Bs) | Lower to Moderate (0.7 – 1.5 T for some NiFe, 0.8T typical for 80% Ni) | High (1.8 – 2.0 T) | Low to Moderate (0.3 – 0.5 T) |

Coercivity (Hc) | Very Low (<4 A/m for 80% Ni) | Low (10-50 A/m) | Low (10-100 A/m) |

Resistivity (ρ) | Low-Moderate | Moderate | Very High |

Typical Usable Frequency | Audio up to ~100s kHz (thin lam.) | Power Freq. (50/60 Hz), some up to few kHz | kHz to MHz range |

Relative Cost | Higher | Moderate | Low to Moderate |

Data sources: Compiled from industry material handbooks (e.g., those referencing ASTM A753 for Nickel-Iron alloys) and typical manufacturer datasheets like those from Carpenter Technology or VACUUMSCHMELZE for their respective Ni-Fe alloy grades.

If your project demands the utmost in magnetic sensitivity, efficiency, and signal fidelity, then Sino’s nickel iron core laminations are not just a component; they’re a competitive advantage. From initial design consultation to precision manufacturing and rigorous quality control, we are your partners in achieving magnetic excellence.

Don’t let suboptimal cores hold your designs back. Reach out to the team at Sino today. Let’s discuss your specific scenario, explore the possibilities, and craft the perfect nickel iron core lamination solution that will make your product truly sing.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.