Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

This article will break down the open loop vs closed loop debate. I will explain what each system does, how it works, and help you decide which motor is right for your project. If you want to understand motor control and make smarter choices, this guide is for you.

Let’s start with the basics. A motor control system is like the brain for any motor. It tells the motor what to do, how fast to go, and where to stop. Think of it as a manager for your electric motors. The control system sends a signal to the motor, and the motor follows the instruction. Whether it’s a simple fan or a complex robot, a control system is in charge.

Many projects fail because the wrong control system was chosen for the motor. The two main types we will discuss are open loop and closed loop. The main difference is one thing: feedback. Understanding this difference is key to getting the overall performance you expect from your motor. A good controller is the heart of any reliable motor operation. These motor controllers manage the input and desired output.

An open loop control system is the simpler of the two. In my early days, this was all we had for many small projects. Here’s how it works: the controller sends a command to the motor, and the motor just does it. It’s a one-way street. The system assumes the motor did the job correctly. It sends the signal and hopes for the best.

This system works without any feedback. There is no sensor to check the motor’s position or speed. The motor operates based only on the initial input. For example, if you tell an open loop stepper motor to turn 90 degrees, it sends the electrical pulses needed to do that. It never checks if the motor actually turned the full 90 degrees. This is a key point in the open loop vs closed loop discussion. The motor simply trusts the command it was given.

Yes, absolutely. This is the biggest selling point of open loop control. From my experience, when a budget is tight and the task is simple, an open loop motor is often the first choice. Because there is no sensor or extra wiring to handle feedback, the whole setup is cheaper and easier to build. It’s a simple and cost-effective solution.

The complexity of the system is very low. You have a controller and a motor. That’s pretty much it. For applications where perfect accuracy isn’t needed, like a simple conveyor belt moving at a constant speed, an open loop motor is perfect. You don’t need to spend extra money on a fancy feedback system. The motor just needs to run, and the open loop control does that job well.

While open loop systems are simple, they have big weaknesses. The problem was that the motor sometimes faced more resistance than we expected. Since there was no feedback, the control system never knew the motor had stalled or skipped steps.

An open-loop stepper motor can lose accuracy and torque. If the load on the motor suddenly changes, it might not have enough power to complete the move, but the system won’t know. These load conditions can be unpredictable. This is a big risk in applications that need high precision. The motor might also vibrate more and have lower efficiency because it often has to be run with more power than needed, just to be safe. It is not ideal for high-speed tasks where errors can add up quickly. This is a system running without a feedback check.

Now, let’s talk about the other side: closed loop motor control. A closed loop system is smarter. It doesn’t just send a command; it also listens for a response. It incorporates a feedback mechanism, usually a sensor of some kind, to check on the motor. This feedback tells the control system what the motor is actually doing.

Think of a closed loop system as having a conversation with the motor. The controller says, “Move to this position,” and the sensor on the motor replies, “Okay, I am now at this position.” This constant communication is what makes a closed-loop motor so powerful. This feedback control loop is what gives the system its name. The motor and controller work together.

This advanced feedback system is key. The motor gets instructions, and a sensor reports back on its speed and position. This is the core of closed-loop control, making the motor far more reliable.

The magic of closed loop control is all in the feedback. The system uses a sensor to monitor the motor‘s output, such as its current speed or position. The sensor sends this information back to the controller in real-time. The controller then compares this feedback with the original command.

If there’s a difference between what was asked and what the motor is doing, the system can adjust its output. For example, if the motor is supposed to be at 100 RPM but the feedback sensor says it’s only at 98 RPM, the controller will increase the power to the motor to compensate. This feedback mechanism allows the system to make corrections on the fly. This system incorporates a feedback loop for continuous improvement. This process of correction is what makes the motor so precise.

When we talk about feedback in a motor system, we are often talking about an encoder. An encoder is a special type of sensor that attaches to the motor shaft. Its job is to monitor the motor’s rotation. A good encoder is vital for a closed-loop stepper motor.

The encoder tells the control system the exact position and speed of the motor. It generates a signal that the controller reads. This real-time data feedback allows the closed-loop system to detect any errors immediately. For a closed-loop stepper motor, the encoder ensures that the motor never loses its place. If it skips a step, the encoder reports it, and the controller can compensate. Without an encoder, you can’t have true closed-loop motor control. This sensor helps detect errors and ensures the motor is where it should be. The encoder is a critical sensor for any closed-loop setup.

The benefits of closed loop control are huge, especially when you need things to be perfect. The first is accuracy. This system delivers precise control. You also get higher reliability because the system can adjust for unexpected changes in the environment or load.

Another benefit is efficiency. A closed loop motor only uses the power it needs. It doesn’t have to be overpowered just in case. This saves energy and reduces heat. Also, these systems can run at a higher speed and with smoother acceleration. The real-time feedback lets the motor push its limits without losing its position. For any robotic arm or high-tech device, closed-loop control provides consistent performance. The system can compensate for environmental conditions. The reliability of the motor is greatly improved with this feedback.

So, the big question: open loop and closed loop, which one should you choose? It all comes down to your needs. Think about three things: cost, simplicity, and the need for accuracy. The loop vs loop decision depends on your application.

Choose an open loop motor if:

accuracy is not a big deal.load conditions are stable and predictable.Choose a closed loop motor if:

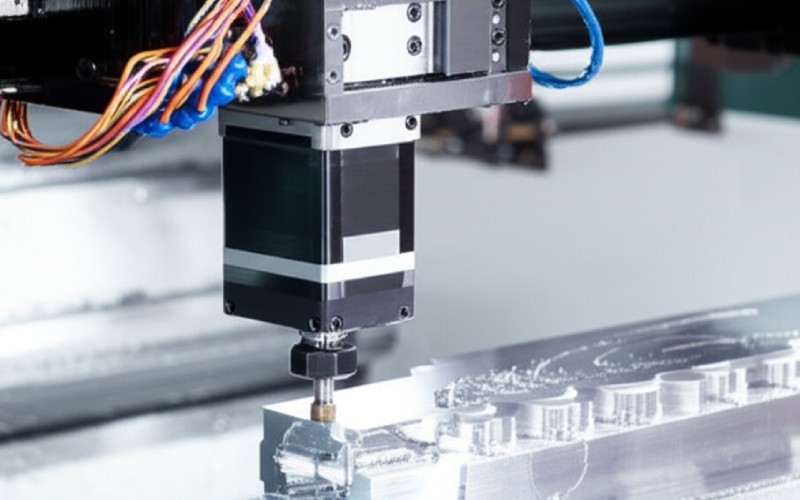

high precision and reliability, like in a 3D printer, robot, or CNC machine.motor will face unpredictable loads or a changing environment.efficiency and want to run at high speeds.This open-loop and closed-loop comparison should guide you. There can be a slight processing delay in a closed-loop system as it checks the feedback, but it’s usually tiny. The decision is a trade-off between cost and performance. A closed loop stepper is superior in performance, but an open loop motor is cheaper. The loop vs choice is critical.

The answer is yes, you often can! The process involves adding an encoder to the motor shaft and using a controller that can accept feedback.

To make the upgrade, you will need two main things: a compatible encoder sensor for your motor and a closed loop controller. The encoder will monitor the motor‘s position, and the new controller will use that feedback signal to adjust the motor‘s movement. It turns your “dumb” motor into a “smart” one. This can be a great way to improve the performance of a machine without replacing every motor. It’s a powerful upgrade that gives you the benefits of closed-loop motor control like better speed and torque control, all based on feedback. It is a popular path for robotics hobbyists. It might take some work to set each parameter, but the improvement in reliability is worth it.