Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

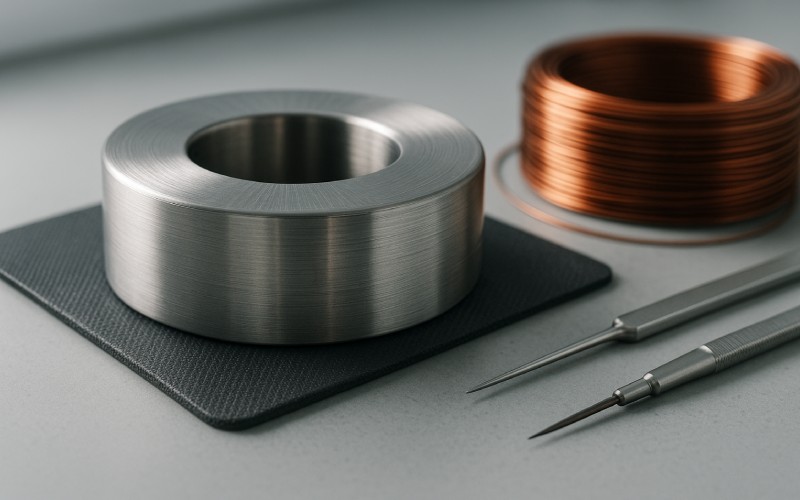

Permalloy cores can feel a bit like a “secret menu” item in magnetics: not right for every job, but magical for low‑level signals, ultra‑low noise, and demanding instrumentation when nothing else quite measures up. This guide distills what matters in the lab and on the line: where permalloy shines, how it compares to ferrites, silicon steels, and nanocrystalline alloys, and how to spec and source cores that actually hit the numbers after heat treat and assembly.

Permalloy, at its core, is a nickel–iron soft‑magnetic alloy. The most famous grade for transformer work is the 80% Ni variant (often called HyMu 80, Moly Permalloy, or ASTM A753 Alloy 4), prized for extremely high initial and maximum permeability and very low coercivity—attributes that let you move flux with tiny magnetizing forces and minimal distortion.

Permalloy’s appeal is simple: at low magnetizing forces (think audio, sensors, instrumentation), nothing couples flux quite as gently. The trade‑off is lower saturation flux density than steels and a need for careful heat treatment and handling. In practice, designers pick 80% Ni when they need vanishingly small excitation current, ultra‑low distortion at small signals, and minimal magnetostriction “singing.”

The numbers below are representative of widely used grades after proper hydrogen anneal. Always confirm with supplier datasheets and your specific lamination thickness and heat‑treat path.

| Core material | Typical relative permeability (initial/max) | Saturation flux density (T) | Resistivity (μΩ·cm) | Typical frequency comfort zone | Notes and common uses |

|---|---|---|---|---|---|

| Permalloy 80 (HyMu 80, A753 Alloy 4) | 80,000 to >350,000 | ~0.6–0.8 | ~47–60 | DC to ~10–20 kHz (laminated/tape‑wound) | Ultra‑high μ, ultra‑low Hc; sensitive to stress; audio/instrumentation laminations and toroids. |

| High Perm 49 (≈48–49% Ni, A753 Alloy 2) | 8,000–150,000 (grade/heat‑treat dependent) | ~1.5–1.6 | ~45–50 | 50/60 Hz to low‑kHz | Much higher Bsat than 80% Ni; a strong choice when you need high μ and saturation headroom. |

| Grain‑oriented silicon steel (CRGO) | Up to ~30,000 (orientation/grade) | ~1.7–2.0 | ~45–50 | 50/60 Hz power | Workhorse for power transformers; not as low loss at tiny H fields as permalloy. |

| MnZn/NiZn ferrites | ~1,500–10,000 (material) | ~0.3–0.5 | ~10^6 | 10 kHz to MHz | Very high resistivity; great for SMPS/high‑frequency magnetics; not for ultra‑low‑level audio at 50/60 Hz. |

| Fe‑based nanocrystalline | >20,000 at 20 kHz; very high at LF | ~1.2–1.25 | ~90–130 | 50 Hz to ~100 kHz | High μ and Bsat; compelling for chokes/CM filters and some HF transformers; losses rise above ~100 kHz vs ferrite. |

Sources underpinning the table: HyMu 80 and Alloy 49 from Carpenter and MuShield; classic permeability/Bsat ranges from Lee’s Electronic Transformers; ferrite and nanocrystalline ranges from vendor datasheets and application notes. Always reconcile to your vendor’s datasheet for the specific grade and thickness you’ll use.

Here’s the uncomfortable truth: you don’t “buy” high permeability—you create it with the right anneal and you can destroy it with careless handling. HyMu 80 and related alloys require a hydrogen anneal (dew point typically below about −40 °C) at roughly 1100–1180 °C for a few hours, followed by controlled cooling. This step relieves stress, grows grains, and unlocks the permeability vendors quote. After final anneal, bending, punching, or even a firm knock can degrade μ; many shops perform the “perfection anneal” as the very last step, and package parts to avoid stress and stray magnetization during shipping.

Permalloy’s mechanical and magnetoelastic behavior also helps keep transformers quiet: the magnetostriction around 80–82% Ni crosses near zero, which reduces strain‑induced noise and helps with ultra‑low hum designs. The exact magnetostriction depends on precise composition and even minor alloying; published work pegs the “zero λ” near ~81.5% Ni.

Eddy losses scale with the square of lamination thickness and frequency. If you halve lamination thickness, you can quarter the eddy‑current loss component (all else equal). That’s why audio‑grade permalloy laminations often live around 0.1–0.2 mm, and why tape‑wound toroids perform so well at low flux densities. Use the simple proportional form Pe ∝ f^2·B^2·t^2 for first‑order trade studies, then validate with your vendor’s core‑loss data.

You’ll get better parts, faster, if your PO reads like a test plan. Include the alloy, product form, heat treatment, and the numbers you will actually measure on receipt.

When you need examples of “real” parts, look at small‑signal audio units built on 80–85% Ni laminations: their wideband linearity at millivolt levels shows what the material can do when the flux stays small and the anneal is right.

In low‑level audio (say a 600 Ω to 15 kΩ step‑up), an 80% Ni core lam stack or tape‑wound toroid lets you run milligauss to low‑gauss flux swings with negligible hysteresis contribution, yielding clean low‑frequency extension at sane sizes. Keep the peak flux density conservative—on the order of a few hundred mT at most for headroom—and avoid DC bias unless you gap the core (which sacrifices μ). For power/instrument transformers where flux runs higher, High Perm 49 offers the headroom to keep distortion down before saturation.

Nanocrystalline cores are outstanding for common‑mode chokes and some power magnetics thanks to high μ and ~1.25 T Bsat, but above ~100 kHz their eddy losses rise versus ferrites. Ferrites dominate at high frequency for precisely this reason. None of that makes them better or worse than permalloy—it simply means you should pick the tool that matches frequency, flux swing, and the signal levels you care about.