Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

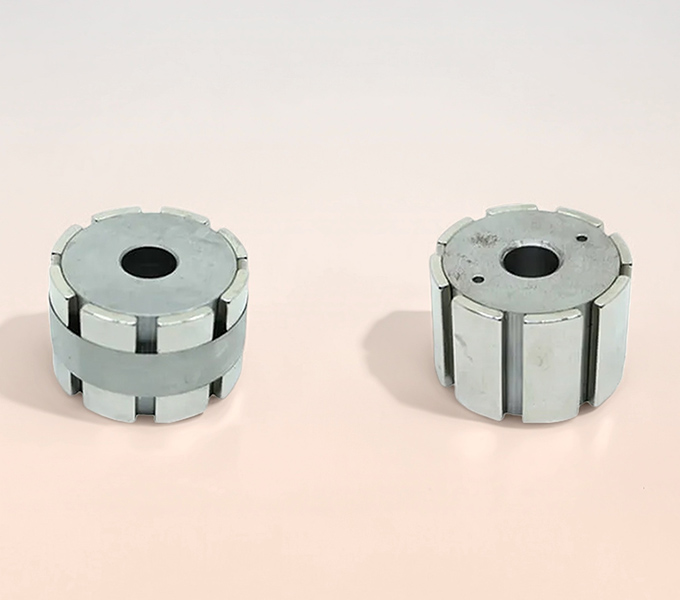

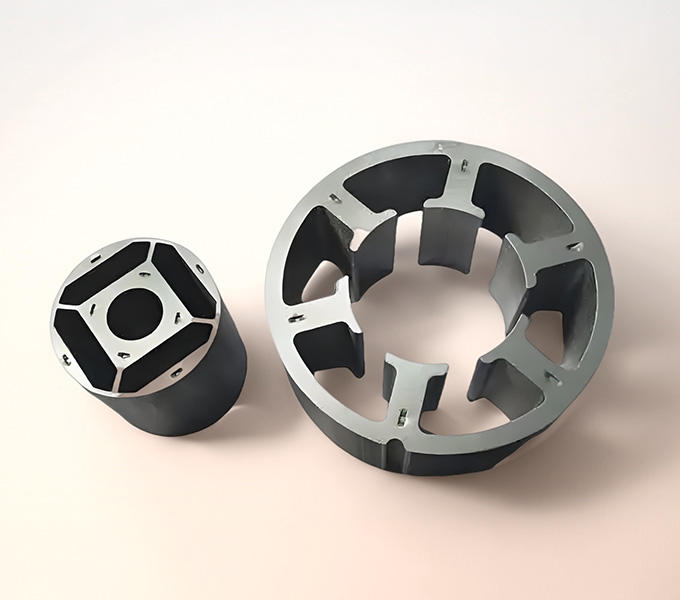

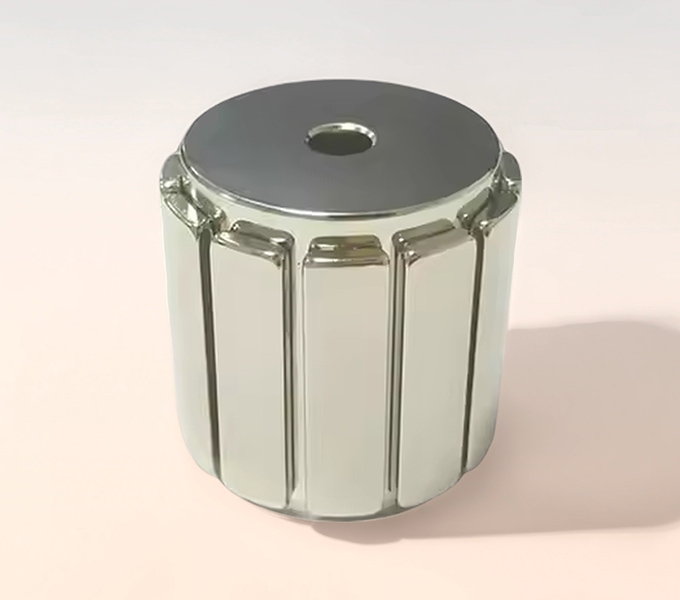

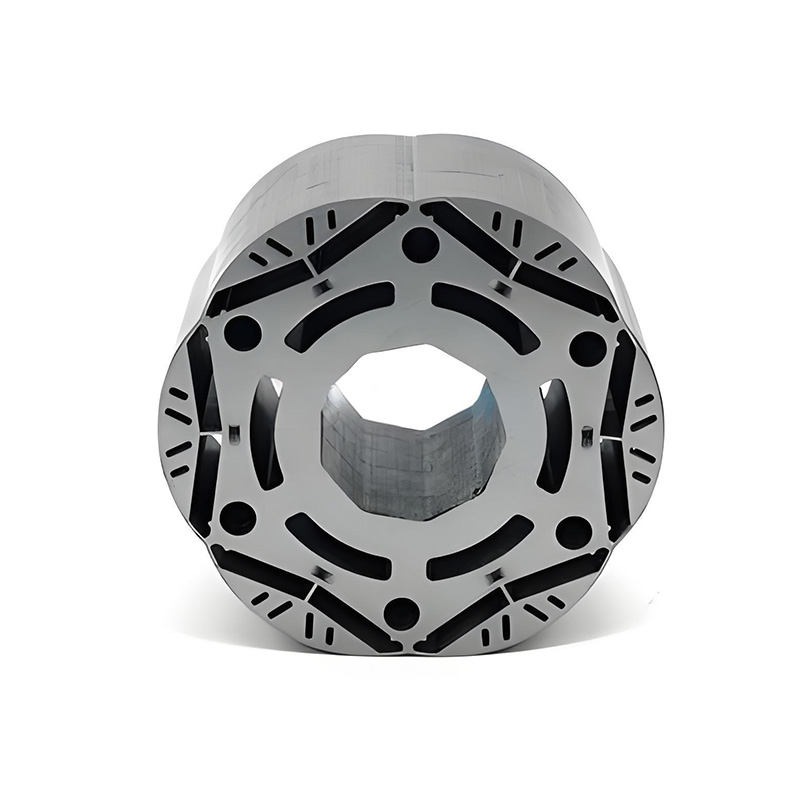

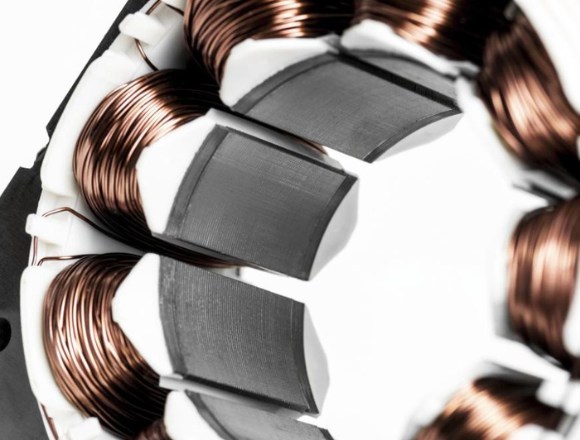

As Sino, a leading maker of permanent magnet (PM) motor laminations, we know that the heart of any powerful electric motor is its magnetic system. Our laminations are not just parts; they are the carefully designed base that determines a motor’s efficiency, power, and reliable operation. They have two very important jobs: accurately guiding the magnetic fields from the permanent magnets and windings, and greatly reducing energy loss from eddy currents.

At Sino, we guide you through Choosing the lamination material that matches the material’s characteristics to your motor’s job description, your performance targets, and your budget, ensuring the heart of your permanent magnet motor stator and rotor is perfectly tuned.

Here’s a quick rundown of some common material families we work with:

Material Type | Sino’s Perspective & Key Advantages | Potential Trade-offs | Common Scenarios We See |

Silicon Steel (e.g., M19, M27, M36, M47 grades, up to high-frequency grades like 20JNEH1200) | Good magnetic performance, cost-effective, excellent for stamping and stacking. Sino stocks various grades for quick turnaround. | Higher losses than some exotics, especially at very high frequencies. | General industrial motors, appliances, HVAC, automotive auxiliaries, many permanent magnet motor stator designs. |

Cobalt-Iron Alloys (e.g., Hiperco®, Vacoflux®) | The heavy hitter for power density. Fantastic saturation flux means more magnetic muscle in a smaller space. Great for high-temp scenarios. Sino can source and process these demanding materials. | Premium price point, can be trickier to stamp and anneal. | Aerospace motors, high-performance electric vehicle (EV) traction motors, specialized robotics. |

Amorphous & Nanocrystalline Metals | The efficiency champions, especially at high frequencies. Super low hysteresis and eddy losses. Sino is equipped for handling these more delicate, often thinner materials. | More brittle, generally higher cost, lower saturation flux density than Co-Fe. Can require specialized stacking/bonding. | High-frequency inductors, ultra-high-efficiency motors, specialized medical devices. |

Nickel-Iron Alloys (e.g., MuMetal®, Permalloy®) | Masters of permeability at low field strengths. Excellent for shielding. | Lower saturation limits, often expensive. | Sensitive sensor applications, magnetic shielding components, some very specialized small motor designs. |

Having the right electrical steel is just the start. Sino knows how to process it into your finished permanent magnet motor rotor or stator stack.

Sino’s manufacturing prowess allows us to expertly handle a wide spectrum of thicknesses, from robust 0.65mm laminations for cost-sensitive, lower-speed motors, all the way down to ultra-thin 0.1mm materials for the most demanding high-frequency applications. But it’s a balancing act. More, thinner laminations for a given stack height can mean slightly higher assembly costs and a lower “stacking factor” (the actual amount of iron versus the total volume, due to insulation taking up space). We work with you to find that sweet spot for your permanent magnet motor stator and rotor.

Each lamination in a stack must be electrically isolated from its neighbors. If this insulation fails, they’ll flow merrily, losses will spike, and your motor will heat up. At Sino, we utilize a range of industry-standard interlaminar insulation coatings (like C3, C5, and C6 coatings as defined by ASTM A976 standards).

Sino’s manufacturing abilities are a leader in the industry, mixing high-speed production with very accurate engineering. We use many different cutting and assembly methods to meet the different needs of our customers around the world. This makes sure we get the best material quality, exact measurements, and a good price.

Our modern factories use the best cutting technologies available today:

The way individual laminations are put together into a stack is very important for the strength, magnetic performance, and heat-handling ability of the motor core. Sino offers a number of advanced ways to put them together:

Quality is extremely important at Sino. We use a full range of quality checks during the manufacturing and assembly process:

Sino’s focus on modern manufacturing and strict quality checks means that every lamination stack we make is precise, high-performing, and reliable. This helps our customers build better electric motors.

So, when you partner with Sino for your permanent magnet motor laminations, what tangible benefits can you expect? It’s more than just precisely stacked steel.

1

By expertly minimizing both eddy current and hysteresis losses through careful material selection (like low-loss silicon steels for your permanent magnet motor stator), precise thickness control, and impeccable insulation, Sino’s laminations allow more of your input electrical power to be converted into useful mechanical work. Think better energy ratings, lower operating costs for the end-user, and a greener footprint.

2

Less energy wasted as heat means your motor runs cooler. A cooler permanent magnet motor stator and rotor translates to longer life for bearings and winding insulation. It can even mean that your permanent magnets are less likely to suffer from irreversible demagnetization at elevated temperatures. This allows you to either build a more robust motor or, in some cases, reduce the complexity and cost of your cooling system.

3

When losses are minimized, you can push more power through a motor of a given size, or, conversely, achieve the required power output with a smaller, lighter motor. This is absolutely vital in scenarios like electric vehicle traction motors, where every gram and cubic centimeter counts for the permanent magnet motor rotor and stator assembly, or in portable power tools where operator fatigue is a concern. Sino’s high-performance laminations are key enablers here.

4

Heat is the enemy of longevity. By keeping core losses in check, Sino laminations reduce the thermal stress on all motor components, contributing directly to a longer, more reliable operational life.

5

Our rigorous quality control, from incoming steel inspection to final stack dimensioning and electrical testing, ensures that the magnetic properties of your permanent magnet motor stator and rotor cores are consistent. This means your motors perform as designed, every single time, reducing your own production line variations and field issues.

At Sino, we don’t just want to be your supplier; we aim to be your partner in motor innovation.

Bring us your permanent magnet motor stator or permanent magnet motor rotor designs early. Our engineers can often suggest subtle modifications to lamination geometry or material choice that can improve magnetic performance, reduce manufacturing costs, or enhance assembly efficiency on your end.

Need to test a new concept? Sino offers quick-turn prototyping services, leveraging flexible tooling or laser cutting for initial samples, so you can iterate faster.

From unique slot shapes and pole counts for your permanent magnet motor stator to complex rotor geometries with specific interlocking or skewing requirements, we have the capability to produce highly customized lamination stacks tailored to your exact needs.

Our commitment at Sino is underpinned by:

The design and quality of your permanent magnet motor laminations are not afterthoughts; they are foundational to achieving the efficiency, power density, and reliability your customers demand. The intricate details of material selection, lamination thickness, insulation integrity, and stacking precision all play a critical role in how well your permanent magnet motor stator and permanent magnet motor rotor will perform.

At Sino, we live and breathe this stuff. We combine decades of specialized experience with cutting-edge technology to deliver lamination stacks that don’t just meet specifications but elevate your entire motor design.

Ready to see how Sino can help you unleash the full potential of your permanent magnet motors? Let’s talk. We’re confident that our laminations can be the bedrock of your next breakthrough product.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.