Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Understanding this core idea, the principle of motor rotation, unlocks the secrets behind so many things we use every day. In this article, you’ll learn exactly how a motor works, what makes it spin in a certain direction, and how we control its speed. No complex math, just a straight, clear look at the magnetic force that powers our world.

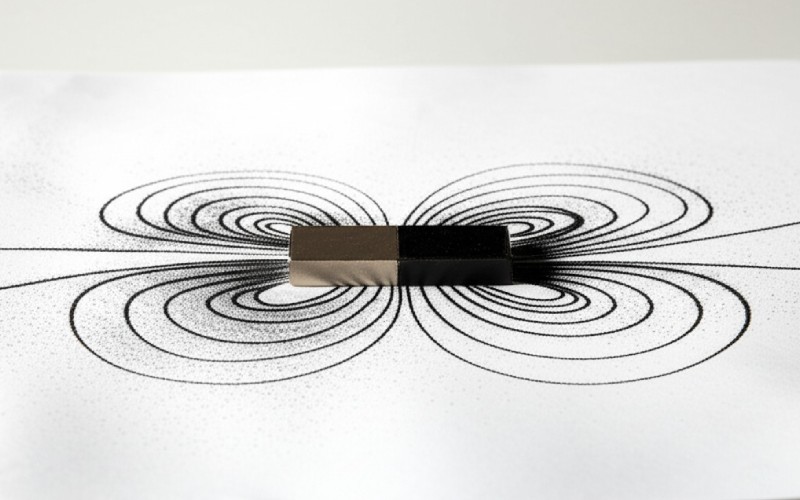

It all comes down to one simple rule of nature: opposites attract and likes repel. Think about playing with two magnets. If you try to push the two north poles together, they push each other away. But if you turn one around, the north and south poles snap together. This simple push and pull is the force at the heart of every single electric motor.

The core principle of motor rotation is using this magnetic push and pull to create a continuous spinning motion. We don’t use two regular magnets, though. We use one regular magnet and one special kind of magnet that we can turn on and off with electricity. By carefully timing the push and pull, we can make part of the motor chase a magnetic field around in a circle. This chase is the rotation you see. The whole amazing design of a motor is built around this simple, powerful principle.

So, how do we use that magnetic force to get something to actually spin? Inside a basic motor, you have two main parts. One part is a stationary magnet (or magnets). The other part is the rotor, which is the part that spins. On this rotor, we wrap a wire into a coil. When we send an electric current through this coil, something amazing happens: it becomes a temporary magnet, called an electromagnet. This is the key to everything.

Now you have two magnets: the fixed one and the new electromagnet on the rotor. The north pole of our electromagnet will be pushed away by the fixed magnet’s north pole and pulled toward its south pole. This push and pull creates a force that causes the rotor to turn, or rotate. This turning movement is the rotational motion we want. The goal of any motor design is to make this magnetic force work as efficiently as possible to produce a smooth rotation.

The electric current is the fuel for the motor. Without it, the coil of wire is just a piece of copper. It has no magnetic power. When we send a current through the wire, we generate a magnetic field. This is the fundamental principle connecting electricity and magnetism. The amount of current we send directly affects the strength of our electromagnet. A small current creates a weak magnetic field, and a larger current creates a powerful one.

This is what gives us control over the motor. The current is what we turn on and off to make the motor go or stop. It’s also what we adjust to change how the motor behaves. The simple act of sending an electrical current into a coil is the trigger for the entire generation of motion. The design of the motor is all about how to best use the magnetic field that this current creates to produce useful mechanical power and rotation.

Yes, absolutely! And the way we do it is surprisingly simple. It goes back to the principle of our electromagnet. The direction the current flows through the coil determines which end becomes the north pole and which becomes the south pole. If the current flows one way, the left side might be north. If we reverse the current’s direction, the right side will become north instead. We have flipped the magnet’s poles.

So, to change the direction of a motor’s rotation, we just need to change the direction of the current flowing to the coil. Let’s say the motor was spinning clockwise. By reversing the current, we flip the rotor’s magnetic poles. Now, the forces that were pushing it clockwise are pushing it the other way. The motor will stop and start to spin counter-clockwise. This ability to easily change direction is a critical feature for many motor applications, from power windows in a car to robots in a factory. It’s a simple change that has a big effect on the motor’s output.

Controlling the speed of a motor is another thing that seems complex but is based on a simple idea. Remember how the strength of the current affects the strength of the magnetic field? Well, a stronger magnetic field creates a stronger push and pull force. This stronger force makes the motor’s rotation happen faster. So, to control the motor’s speed, we just need to control the amount of power it gets.

We usually do this by changing the voltage. A higher voltage pushes more current through the coil, which creates a stronger magnetic field, which results in a higher speed. A lower voltage means less current, a weaker field, and a slower speed. Another factor that affects speed is the load on the motor. If a motor is trying to spin a heavy fan blade, it will have a lower speed than if it’s spinning with nothing attached. The motor’s design and the voltage you supply work together to determine its final rotation speed.

Motor design is everything. While the basic principle is the same, the actual design of a motor changes everything about its performance. The design determines the motor’s power, speed, and efficiency. For example, the material used for the magnets, the number of coils, and the quality of the bearing that the motor shaft spins in all have a huge impact. A cheap design might use weaker materials and get hot easily.

The intended use of the motor dictates its design. A tiny motor for a vibrating cell phone has a very different design than a large motor used to power an electric car. The phone motor needs to be small and use very little power. The car motor needs to produce a huge amount of power and torque. The application drives the design choices. A good motor design is one that perfectly matches the job it needs to do, making the best use of the rotation principle for that specific task.

When we talk about motors, we often hear the word “torque.” Torque is simply the amount of twisting force the motor can produce. It’s not the same as speed. You can have a motor that spins very fast but has very little torque, meaning you could stop it easily with your fingers. You can also have a motor that spins slowly but has a huge amount of torque, meaning it can turn something very heavy.

Torque is the force that gets the rotation started. A motor needs to generate enough torque to overcome inertia (the desire of an object to stay still) and any load it’s connected to. For example, a blender’s motor needs high torque to start spinning the blades when the jar is full of ice and fruit. Once it gets going, the speed might be more important. The rotational force of a motor is a combination of both its torque and its speed, and a good motor design provides the right balance of both for its application.

For many simple motors, especially DC motors, the speed of rotation is directly related to the voltage you give it. A simple, non-exact calculation or rule of thumb is that if you double the voltage, you will roughly double the motor’s speed, assuming the load stays the same.

A more formal, but still basic, calculation might look something like this: Speed is proportional to (Voltage – (Current x Resistance)). Don’t worry about the second part too much. The main thing to see is that Voltage is the main driver of speed. A real-world calculation is much more complex and includes factors like the motor’s design, the magnetic flux, and the load. But for a basic understanding, just remember this: more voltage equals more speed. This simple calculation is a great base for understanding motor control.

There are many different types of motors, but most of them still use the same core magnetic principle we’ve been talking about. One of the most common and easy-to-explain types is the DC motor. “DC” stands for “Direct Current,” meaning the electricity flows in one straight direction. These are the types of motors you find in toys, drones, and many portable electronics. They are simple in their design and easy to control.

The DC motors we’ve discussed use brushes to switch the direction of the current in the coil as it spins, which keeps the rotation going. There are also brushless DC motors, which are more efficient and use electronics to switch the magnetic field. There are also AC motors, which run on the alternating current from your wall outlets. While the exact mechanism can change, the fundamental idea—a rotating magnetic field causing a mechanical rotation—is the foundation for nearly every motor type.

To see how important this principle is, you just have to look at a company like Nidec Corporation. They are a world leader in making motors. They don’t just make big, powerful motors; their specialty is in the design and production of millions of small, precise motors that are all around us. The tiny motor that spins the hard drive in a computer, the motor that vibrates your phone, and the small fans that cool your electronics—chances are, they mastered the design for that specific use.

They take the fundamental principle of motor rotation and apply it with incredible engineering. They figure out the best material, the most efficient coil design, and the perfect electronic controls to create a motor that does its job perfectly with as little power as possible. Their work shows how this one basic scientific principle can be used to create a huge range of products that power our modern lives. The success of a company like this is built entirely on mastering the generation of rotational force through magnetism.