Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

This post is all about the huge relevance of rotor balancing. If you run any type of kind of maker with parts that rotate, recognizing why balancing issues is key. This article will share why keeping an excellent equilibrium in your rotor can conserve you a ton of frustrations and money. We’ll consider just how rotor balancing keeps your tools running smooth and for a long, very long time.

Consider a rotor — that’s the part in your electric motor that spins, or tries to turn. Ideally, the weight of this rotor needs to be spread out flawlessly even all over the point it rotates on, its axis of rotation. When it’s not flawlessly even, we call that unbalance. It means one side of the rotor is larger than the other. This imbalance is a typical problem. This irregular weight circulation produces an issue when the rotor begins to rotate. The much heavier side wants to pull away from the facility. This drawing is a centrifugal force. The faster the rotor tries to revolve, the stronger this pressure comes to be. So, rotor unbalance is generally an irregular weight in a spinning component that intends to throw points off equilibrium. This preliminary inequality is what we need to fix with rotor balancing. Also a little bit of unbalance can create big problems in a maker. We needed to carry out cautious rotor balancing to obtain it smooth once again. Making certain the rotor has great balance is the first step to a healthy and balanced device.

Now, you could be asking, “Okay, Robert, so it’s uneven. Why is this balance so important?” Well, from my experience, the relevance of rotor balancing can not be overemphasized. It’s not almost making the equipment run quieter, though that’s a nice perk. Appropriate equilibrium is crucial for the wellness and lifespan of the motor and the entire machinery. When a rotor is out of equilibrium, it creates resonance. This vibration isn’t just a small aggravation. It puts a big pressure on several components of the maker, especially the bearing elements. These components are not created to deal with consistent shaking. Consider it like driving an auto with a severely balanced tire– the entire car and truck trembles, and at some point, points start to wear or break. Excellent rotor equilibrium prevents this. Correct rotor balancing makes sure that the machine operates smoothly and efficiently. It safeguards your financial investment. So indeed, stabilizing matters a lot. It’s fundamental for a safe and dependable procedure.

Let’s come down to the basics of what an out of balance rotor does. Unbalance creates resonance. This constant trembling resembles a little hammer hitting parts of your electrical motor over and over once again, thousands of times a minute. The very first targets are generally the bearings. A bearing is designed for smooth rotation, except dealing with heavy side lots and shocks from resonance. An out of balance rotor can destroy a bearing a lot faster than normal. This too much resonance doesn’t quit at the bearings. It takes a trip via the shaft to various other components of the electric motor and also to the entire machine framework. This can loosen screws, split welds, and damage sensitive elements. The goal of rotor balancing is to quit this destructive vibration. In addition, an unbalanced rotor makes the electric motor function tougher. It has to combat those irregular pressures. This indicates it utilizes a lot more power, which costs you money. It can additionally bring about the motor performing at high temperatures, which can reduce its life expectancy. Great rotor balance brings about a better, cooler, and longer-lasting electrical motor.

When we speak about rotor unbalance, it’s not a one-size-fits-all problem. Recognizing these assists us to appreciate the balancing procedure. The easiest is static unbalance. Visualize a rotor, like a basic disc or flywheel. If it has a heavy place, that spot will naturally intend to resolve near the bottom when the rotor is not spinning. This unbalance can often be remedied in a single plane. Then there’s something called couple unbalance. This is a little bit a lot more complicated. With a couple unbalance, you have two equal heavy spots, yet they get on opposite sides of the rotor and at different factors along its size, or axis of rotation. When the rotor is still, it could appear in balance. But once it starts to rotate, these pressures develop a tottering or rocking movement. This kind of unbalance requires adjustment in two planes. Ultimately, one of the most typical types we come across in real-world machinery like a turbine or compressor is dynamic unbalance. This is essentially a combination of both static unbalance and couple unbalance. The rotor has an unequal weight distribution both around its facility and along its size. To deal with dynamic unbalance, we require dynamic balancing, which deals with the unbalance in at the very least two planes while the rotor is rotating. This is why the significance of rotor balancing is typically reviewed with dynamic balancing techniques.

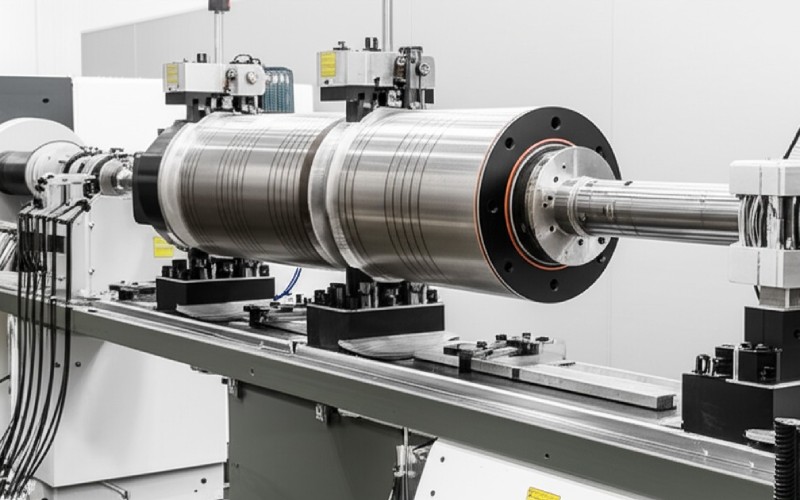

Safe bet! The balancing process for a rotor is quite an interesting bit of engineering. First, the rotor (maybe an armature, a shaft, a fan, a pulley, or perhaps a crankshaft) is normally removed from the electrical motor or equipment, if it’s not being stabilized in position. It’s after that installed on a special balancing machine. This maker has sensors. When the rotor is made to rotate (occasionally at reduced rates, sometimes closer to its operating conditions), these sensor devices find the vibration caused by any kind of unbalance. The device’s computer then identifies two crucial things: how much unbalance there is, and where the heavy place (or areas) are located on the rotor. This tells the specialist specifically where the inequality exists. As soon as the amount and place of the unbalance are recognized, the next action is correction. This is normally done by either adding or removing small amounts of weight at specific locations on the rotor. For instance, weight might be added by welding little pieces of steel, or gotten rid of by drilling little holes. The goal is to make the weight distribution around the axis of rotation evenas possible to achieve a great balance. After the adjustment, the rotor is rotated again to examine the brand-new balance. This balancing process may be repeated a few times to get the equilibrium ideal, attaining well balanced rotors.

Unlike static balancing, which can often be done when the rotor is still and just fixes for unbalance in one plane, dynamic balancing measures and corrects unbalance when the rotor is in fact rotating. It also addresses unbalance in two planes (or occasionally a lot more for very long or flexible rotors). Why is this a large offer? Well, lots of rotors, particularly those that are long like a shaft or cylinder, or those that run at broadband like a generator rotor, will have dynamic unbalance. This implies the unbalance isn’t simply a solitary heavy place; it’s more complicated, involving forces that trigger the rotor to wobble end-to-end as it tries to turn. A straightforward static balance will not fix this. You need dynamic balancing to precisely counteract these wobbling forces and accomplish real rotor equilibrium. For things like high-speed electrical motor armatures, follower impellers, pump impellers, and also steam turbines, dynamic balancing is not just advised, it’s necessary for their total performance and longevity. It assists to achieve that critical balance needed for smooth operation. Without dynamic balancing, these sorts of rotor components would certainly suffer from excessive vibration, leading to all the problems we have actually spoken about, like early wear and damage.

Yes, absolutely! It’s not just a thinking game when it involves how much equilibrium is “good enough” for a rotor. There are industry balancing standards that provide designers and technicians guidelines. Among the most common ones is ISO 1940-1. These standards help define the acceptable level of staying unbalanced for different kinds of rigid rotors based on their mass and maximum operating speed. These balancing standards give what’s called a balancing grade (typically G grade). A lower G number suggests a tighter, more exact balance is called for. As an example, a rotor for a high-precision grinder could require a really low G quality, like G1 or G2.5, indicating it needs an extremely good balance. A rougher device part, like a flywheel for a slow-speed engine, may be fine with a higher G quality. The stabilizing grade assists ensure the rotor is Aankaproperly well balanced for its specific work. Complying with these balancing standards is necessary for a couple of factors. It guarantees consistency in rotor balancing top quality. It assists suppliers generate reputable machinery. And for you, the individual, it means you can have confidence that the rotor in your electrical motor or other machine has a suitable level of equilibrium for risk-free and trustworthy procedure and a great service life. Abiding by a specific balancing grade guarantees the rotor will perform well under its designated running conditions.

When you have well balanced rotors in your equipment, the distinction in overall efficiency can be like evening and day. First of all, a rotor with excellent balance runs smoothly. This decrease in vibration suggests the device can do its task more precisely and successfully. Consider a maker device; if its electric motor or spindle rotor is shaking, it can not make exact cuts. Proper balancing solutions. Secondly, well balanced rotors bring about better power performance. An out of balance rotor creates internal pressures that the electrical motor needs to combatonuclear_against. This battle wastes energy. When the rotor remains in equilibrium, the motor does not have to work as hard to rotate the shaft, so power intake decreases. This is a straight expense savings for you. Finally, a smooth procedure because of good rotor equilibrium decreases tension on all elements. This implies much less wear and tear, bringing about increased integrity and a much longer life expectancy for the motor and the whole device. You’ll experience less downtime and fewer unanticipated malfunctions. So, well balanced rotors are not just about silent operation; they are about improving the essential efficiency of the machinery. The importance of rotor balancing beams through below.

Ignoring rotor unbalance can lead to some extremely bad outcomes. In the short term, you’ll manage sound and vibration. This might just look like an annoyance, but it’s an indication. This vibration brought on by inequality puts added tension on bearings, seals, couplings, and the maker framework itself. This often brings about early wear of these components. If this unbalance is left unaddressed, the resonance can worsen. Bearings can stop working, causing the rotor to seize or harm the shaft. In an electric motor, severe unbalance can lead to overheating and winding failing. The worst-case circumstance? A catastrophic failing of the device. This implies major damages, pricey repair work, and significant downtime, not to mention safety dangers. So, while it might look like an extra step, executing rotor balancing is a crucial preventive measure. It helps avoid these serious consequences. The tiny price and initiative of making certain proper rotor equilibrium fade in comparison to the prospective prices and threats of running a device with a considerable unbalance. It’s a clear situation where stabilizing is very important for safety and reliability.

Proper balancing is an investment that pays you back, usually sometimes over. The biggest way it saves you money is by prolonging the lifespan of your electrical motor and other turning machinery. When a rotor has great equilibrium, there’s less resonance, which indicates less deterioration on bearings, seals, and other important components. This straight converts to fewer malfunctions and a much longer life expectancy of the motor. Think of the cost of downtime. When a vital device breaks down as a result of a problem caused by inequality, your production stops. That’s shed cash, every min. Rotor balancing significantly lowers the threat of these unanticipated failings, pommes_meaning_more_uptime_and_even_more_efficiency. You’ll additionally save on costly fixings. Changing a failed bearing or a damaged shaft is expensive. Avoiding these issues with great rotor equilibrium is much cheaper. Ultimately, a machine with a well balanced rotor runs extra efficiently. It uses much less energy due to the fact that it’s not combating against those unbalanced pressures. Over time, these power cost savings can add up. So, from decreasing repair expenses and downtime to cutting power prices and enhancing the life span of your devices, the expense savings from constant rotor balancing services are extremely real. Achieving an accurate balance is vital to these savings. The significance of rotor balancing actually hits home when you check out the lower line.