Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Designers love adding poles, tweaking magnets, or changing control strategies. But two of the quietest, highest-leverage knobs in a slotted electrical machine are purely geometric:

They live in the millimeter range, yet they shape the air-gap flux waveform, loss distribution, torque ripple, and even noise. Papers on stator core shaping and slot design show that careful tuning of these tiny features can shift iron losses by tens of percent and change magnetic noise dramatically.

Most blog posts treat them as a line in a CAD screenshot. Let’s not do that.

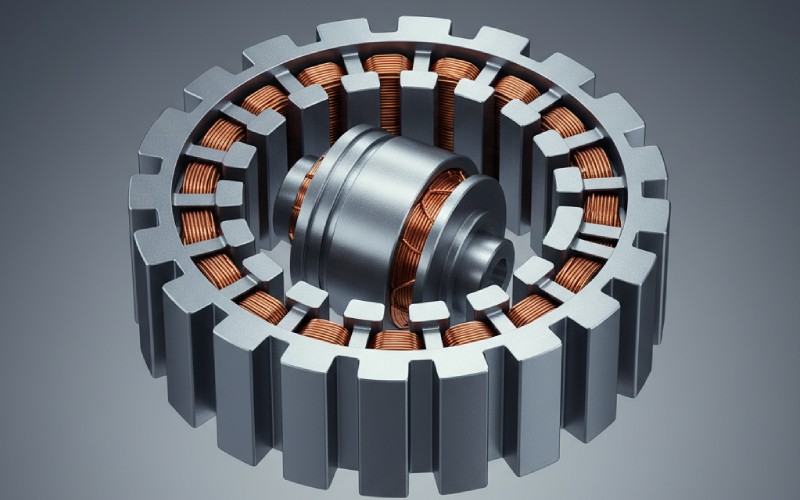

Picture a stator tooth: a tall beam of laminated steel, necking down into a narrow tooth top that faces the rotor. The tooth-tip radius is the rounding at the inner corners, where the tooth meets the air-gap. The slot opening is the gap between neighboring tooth tips.

Those two dimensions sit right where everything happens:

Manufacturing houses that specialize in electrical steel laminations explicitly call out slot opening, tooth tip radius, and bridge width as primary dimensions to control because they directly influence air-gap flux, harmonic content, losses, and noise.

Before we tweak geometry, it’s worth revisiting what we’re actually trying to move: loss components. In any slotted PM or induction machine, efficiency is primarily eaten by:

Tooth-tip radius and slot opening are mainly iron-loss and AC-loss knobs, not copper-I²R knobs. Modern iron-loss models typically decompose core loss into three parts — hysteresis, classical eddy current, and an “excess” or anomalous component that captures local high-frequency microscale effects.

Detailed mapping studies on high-speed PM machines show that stator yoke and teeth dominate total core loss, with the tooth top being especially sensitive to changes in load and flux pattern. Under some conditions, the tooth-top loss growth with load is hundreds of percent larger than that in the yoke.

That is exactly the region tooth-tip radius and slot opening reshape.

Start with the tooth tip radius ( R_t ). Imagine shrinking it towards zero: you get a very sharp tooth corner. Flux lines in the tooth want to spread into the air gap; a sharp corner forces them through a tight “bottleneck,” creating flux crowding and local saturation at the tooth top.

Studies on stator core shaping show that introducing suitable radii at tooth corners (often discussed at the root, but the same intuition applies to the top) can noticeably reduce local core losses by easing those peak flux densities.

On the other hand, if you over-round the tooth tip, you’re effectively widening the air gap locally:

Sensitivity analyses on tooth-coil PMSMs, where tooth-tip dimensions are swept, show exactly this trade-off: torque density is strongly influenced by tooth tip width/radius, but there is a diminishing returns region where further rounding spoils torque for modest loss gains.

The “sweet spot” is usually a moderate radius: large enough to avoid corner saturation and to soften flux gradients, small enough to keep decent permeance and flux focusing.

The slot opening ( b_{so} ) is the clear distance between tooth tips at the air-gap. It has a complicated relationship with losses because it reshapes the permeance waveform around the air-gap.

Historically, open slots were known to introduce extra loss even in simple test cores; classic work in the 1930s already pointed out that losses due to open slots must be separated from “true” iron loss when characterizing materials.

More recent research is clearer:

And then there’s the winding: as conductors move closer to the slot opening—where leakage and fringing fields are larger—AC losses increase significantly.

So slot opening pulls on at least four strings: iron loss, torque, AC loss, and noise.

You can treat tooth-tip radius and slot opening as just two more design parameters in a parametric optimization, but they behave differently from global quantities like stack length or magnet thickness. They mostly affect field quality and local loss distribution, not just bulk performance.

Good news: that makes them perfect targets for a focused sensitivity analysis.

In practice you’ll combine 2D/3D FEA with an iron-loss model (Bertotti-type or improved variants) and possibly an AC winding-loss model.

To make the trade-offs more concrete, the table below summarizes qualitative effects of changing tooth-tip radius and slot opening, combining trends seen across several machine types.

⚠️ The table is intentionally qualitative. Exact sensitivities are machine-dependent—slot/pole combinations, magnet type, speed, and material all matter.

| Design change | Primary effect on flux & harmonics | Typical impact on losses (qualitative) | Other side-effects / notes |

|---|---|---|---|

| Slight increase in tooth-tip radius | Smooths flux at tooth corners, marginally higher local air-gap reluctance | ↓ Tooth-top iron loss hotspots; ≈ Yoke loss; small or neutral effect on total stator iron loss | Often “free” from torque viewpoint if radius is modest |

| Large increase in tooth-tip radius | Significantly weaker flux focusing at tooth top | ↓ Tooth-top iron loss; may ↓ overall stator iron loss but not proportionally to torque reduction | Noticeable torque / EMF drop; may reduce cogging slightly |

| Decrease in tooth-tip radius (sharper corner) | Stronger flux crowding at tooth inner corners | ↑ Tooth-top iron loss strongly; potential ↑ in excess loss due to steep local gradients | May boost torque a bit; worse for NVH and hotspot temperatures |

| Widen slot opening (slot area ≈ constant) | Flatter permeance waveform, higher reluctance in tips, stronger slot harmonics | Often ↓ stator tooth core loss; possible ↑ rotor or stray loss; ↑ AC copper loss near slot top if conductors are close | Can increase torque ripple and magnetic noise |

| Narrow slot opening (slot area ≈ constant) | Stronger flux focusing, reduced slot harmonics | ↑ Tooth-top iron loss (higher local B); yoke loss may change little; ↓ slot-harmonic-driven iron loss in some machines | Good for torque density, but winding insertion is harder |

| Move conductors closer to slot opening at fixed opening | Higher leakage field through conductors | ↑ AC copper loss and strand heating, especially at high frequency or PWM supply | Sometimes done for thermal/mechanical reasons—needs checking |

You’ll see echoes of these trends in detailed studies of stator core loss distribution, where tooth-top losses are the most sensitive to changes in field pattern and load.

All of this beautiful sensitivity analysis assumes the machine you build actually matches the geometry you simulated.

In reality, tooling and stamping tolerances smear out tooth-tip radius and slot opening. Lamination suppliers highlight that tight die tolerances are essential to keep slot opening, tooth-tip radius, and bridge widths within design targets; otherwise, losses and noise drift away from the predicted values.

Sensitivity studies on stator geometries also show that unequal tooth widths or small deviations in tooth geometry can shift flux linkage and winding factor enough to change both torque and loss distribution.

If you’re pushing efficiency to 95–98%, sloppy control of a 0.1–0.2 mm slot-opening tolerance can erase weeks of FEA optimization.

If you mentally “follow the flux,” tooth-tip radius and slot opening stop being just dimensions and start feeling like tuning knobs for how hard the steel has to work.

Literature across induction, radial-flux, and axial-flux PM machines shows that:

Your job as a designer is to decide where to spend and where to save:

A structured sensitivity analysis, focused just on tooth-tip radius and slot opening, gives you that trade-off map instead of relying on hunches. Once you have that map, every future machine you design benefits—because these two tiny dimensions quietly touch almost every loss mechanism that matters.