Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Many people wonder about single-phase motors versus three-phase motors. What’s the genuine distinction between single phase and three phase power for a motor? And extra notably, which type of motor is ideal for your job? Choosing the proper motor is incredibly crucial. It can conserve you money, make your devices work better, and stop migraines later on. People select the incorrect motor and wind up with a device that doesn’t have enough power to run or one that burns out as well promptly. So, in this article, I’m going to detail the essential differences between single-phase and three-phase motors in simple terms. By the end, you’ll have a much clearer idea of exactly how these motors work and which one to select for your requirements. This knowledge will aid you make smart selections for any type of motor application.

Let’s start with the essentials. What is a single-phase motor? Well, as the name suggests, this type of motor uses a single-phase power supply. Think of the routine power in your house– that’s generally single-phase power. A single-phase motor is an AC motor that takes this single alternating voltage from the power supply to convert electrical power into useful mechanical power. This motor is created to run on a system where the power is supplied through generally two wires (one hot wire and one neutral wire, or sometimes two hot wires). The means a single-phase motor works involves producing an electromagnetic field inside the motor. However, with just one phase of current, this electromagnetic field just pulses back and forth; it does not normally rotate. This suggests single-phase motors are not self-starting on their own. To get the rotor (the rotating component of the motor) to start turning, they need a little help. This aid often originates from an extra component, like a capacitor or a special starting winding (or auxiliary winding), which develops a 90° phase change or a momentary 2nd phase to offer the rotor that preliminary push. This motor is a common sight in numerous homes. You’ll find a single-phase motor in lots of everyday items. They are wonderful for work that doesn’t require a significant quantity of power. This type of motor is less complex in design compared to its three-phase cousin. Because this electric motor makes use of an easier power supply, it’s excellent for areas where only single-phase power is available. The motor itself is usually more economical to acquire originally.

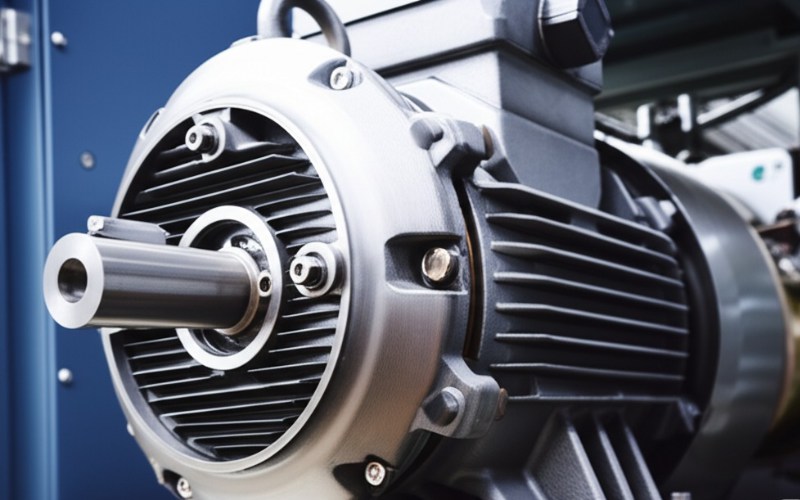

Now, let’s speak about the three-phase motor. This motor is a bit even more of a giant. A three-phase motor utilizes a three-phase power supply. Instead of one wave of electricity, a three-phase power supply delivers three alternating currents that are completely timed. Imagine three different waves of current, each reaching their top at various, equally spaced minutes. These currents are spaced 120 degrees apart. This creates a much more constant and smooth flow of power to the motor. This special power supply is what makes a three-phase motor truly radiate. When these three alternating currents flow into the motor’s windings, they naturally create a revolving electromagnetic field. This is a big deal! It implies the three-phase motor is self-starting. It doesn’t need extra parts like a capacitor simply to start. The rotor in a three-phase motor begins rotating smoothly as soon as power is supplied. This motor layout is very effective. A three-phase induction motor is a very typical kind of motor in industrial applications. Due to the fact that the motor makes use of a three-phase power setup, it can supply more power a lot more successfully than a single-phase motor of the very same size. This makes the three-phase motor perfect for larger jobs. The three-phase induction motor is also known as an asynchronous motor because the rotor turns at a rate a little less than the magnetic field rate.

You may be thinking, “A motor is a motor, right? Can I not just make use of any motor?” Well, not rather. It really does matter! Picking between a single-phase or three-phase motor depends greatly on the work the motor requires to do and the available power supply. Using the wrong motor can result in all types of troubles. It is necessary to match the motor to its power demands. If you make use of a single-phase motor for a work that needs a great deal of power, like running a huge pump or hefty machinery, the motor will certainly struggle. It may get too hot, wear out swiftly, or merely not be able to do the work. It is generally designed for lower power applications contrasted to a 3-phase motor. On the other hand, using a big three-phase motor for a tiny job could be excessive and unnecessarily expensive, especially if you don’t currently have a three-phase power supply available. The vital distinctions in exactly how these motors are frequently developed and operate mean they are matched for various jobs. A single-phase motor is excellent for low power needs, while a three-phase motor succeeds with heavy loads. The performance and lifespan of your motor rely on making the right selection. Every motor has its function.

Understanding the power supply is essential to understanding the difference between single phase and 3 phase motors. Single-phase power is what the majority of homes and small companies have. It uses a single alternating voltage. This power supply generally entails two primary wires: one hot wire carrying the current and a neutral wire to complete the circuit. It’s easier to mount and take care of for general use. This single-phase power supply is excellent for lighting and day-to-day devices that make use of a single-phase motor. Three-phase power, on the other hand, is more usual in commercial applications and larger industrial buildings. A three-phase power supply makes use of three alternating currents. These 3 currents run out of sync with each other by 120 levels. This setup, often using three hot wires and one neutral wire (in a Wye arrangement) or just three hot wires (in a Delta setup), delivers a more consistent and balanced stream of power. This makes it optimal for running large, powerful electrical motors like a three-phase induction motor. So, the power supply available frequently dictates what sort of motor you can use. You can’t just plug a three-phase motor right into a standard home outlet that gives single-phase power without special (and frequently costly) converters. The motor needs the ideal kind of juice to run properly and successfully.

Single-phase electric motors are not self-starting. This is a critical point. A single-phase motor attached directly to a single-phase power supply will just hum because its electromagnetic field pulses backward and forward instead of revolving. It needs a little trick to get the rotor to spin. The motor needs a means to produce a temporary revolving effect. To attain this, single-phase electric motors typically use a beginning device. One usual approach includes a capacitor. The capacitor is utilized with an auxiliary winding (also known as a starting winding) (a second set of windings in the motor) to produce a phase shift in the auxiliary winding. These 90° stage shift aids create a weak rotating electromagnetic field, just enough to obtain the motor going. Once the motor is up to speed up, the starting circuit and capacitor are usually switched off. Various other kinds, like the shaded post induction motor, utilize various methods with a “shielding coil” to create this beginning push for the motor. This demand for a beginning system makes the single-phase motor a little bit more complex in some ways than a basic three-phase motor, although it uses an easier power supply. Without this starting aid, your single-phase motor would just sit there and make sounds, not able to convert electrical power into mechanical power. This motor relies upon these smart techniques.

Currently, when we check out a three-phase motor, the starting story is much easier. Yes, it’s generally easier for a three-phase motor to start! The magic lies in the three-phase power supply itself. Because this motor uses a three-phase power source with its three alternating currents flawlessly out of step, it normally generates a rotating magnetic field within the motor as quickly as power is used. This suggests three-phase electric motors are naturally self-starting. You do not need an exterior capacitor or complex starting windings simply to obtain the rotor to spin. The style of the motor and the nature of the three-phase supply interact beautifully. This makes the beginning process for this kind of motor extremely trustworthy and straightforward. The motor simply begins to convert electrical power into mechanical energy smoothly. This self-starting capacity is among the large advantages of a three-phase induction motor, specifically in industrial applications where integrity and simpleness of operation are essential. The motor simply functions. It’s a more stylish remedy for starting a motor without extra components only for that purpose. The 3-phase induction concept is really efficient.

So, when is a single-phase motor the best tool for the work? I’ve found that single-phase electric motors are commonly the best selection when your power needs are relatively reduced and you just have accessibility to a single-phase power supply. This covers a lot of ground! Consider a lot of home devices: fridges, followers, washing devices, and power tools like drills or small saws. These all commonly utilize a single-phase motor. A single-phase motor is additionally a good pick if the initial price of the motor is a huge aspect. They are typically less expensive to buy than three-phase electric motors. If you’re running a tiny workshop or require a motor for a hobby task, a single-phase motor will certainly do the trick completely. It’s a workhorse motor for day-to-day tasks. This type of motor is additionally functional where simpleness of the electric installment is necessary. Considering that it utilizes a single-phase power supply to convert electrical energy into mechanical work, the circuitry is much less complex. For numerous motors that make use of around the home or in light business settings, a single-phase motor provides a great balance of efficiency and expense. This motor can manage several low power jobs efficiently.

Currently, when do you absolutely need a three-phase motor? My experience informs me that a three-phase motor becomes the go-to option when you’re managing hefty lots and need even more power and performance. These electric motors are well fit for commercial applications. You’ll see a three-phase induction motor utilized to power conveyors, huge pumps, compressors, grinding equipment, and other sturdy equipment. If your motor application needs high beginning torque (the turning force to get points relocating) and smooth, continual operation under lots, a three-phase motor is superior. Since this electric motor makes use of a three-phase power supply to convert electrical energy into mechanical work, it supplies power extra constantly, bringing about smoother operation and less vibration than an equivalent single-phase motor. The motor is built for a challenging job. An additional large reason to pick a three-phase motor is effectiveness, specifically for larger electric motors that compete numerous hours. They generally have better efficiency and power factor than single-phase motors, suggesting they can do even more to deal with much less lost energy. If you have accessibility to a three-phase supply, and the motor needs to run big devices, a three-phase motor is often the far better, much more robust option. The three-phase induction motor design is perfect for these scenarios.

Let’s directly contrast the performance. The essential distinctions between single-phase and three-phase motors are rather significant. A three-phase motor normally offers higher efficiency and a better power factor. This indicates more of the electrical power is converted into useful mechanical energy, and much less is lost. This motor is a solid entertainer. A three-phase motor likewise provides a more continuous torque, which indicates it runs smoother with much less vibration contrasted to a single-phase motor. Think about it like an engine: a single-phase motor is like a single-cylinder engine (a little bit jerky), while a three-phase motor is like a multi-cylinder engine (much smoother). This smoothness can be vital for the durability of both the motor and the tools it drives. The differences between single-phase and three-phase performance are clear right here. When it pertains to starting, as we’ve discussed, the three-phase motor is self-starting, while the single-phase motor needs aid (like a capacitor). This makes the three-phase motor less complex in that respect. Also, for the very same horsepower rating, a three-phase motor is frequently literally smaller sized and lighter than a single-phase motor. This can be a factor if the area is tight for your motor. The single-phase vs three-phase argument commonly comes down to power and level of smoothness.

Yes, normally speaking, three-phase electric motors are much more efficient than single-phase electric motors, especially in higher horsepower scores. Why is that? A huge factor is that the three-phase power supply is naturally a lot more balanced and delivers power a lot more continuously. This minimizes the motor losses — power that’s wasted as heat. A three-phase motor does not need to work as tough to maintain its activity since the power is supplied in that smooth, rotating method. Since they are more efficient, three-phase motors require less electrical input power to produce the same amount of mechanical output power as a single-phase motor. This indicates that over the life of the motor, a three-phase motor can save you cash on electrical power bills, especially if the motor runs regularly or for extended periods. This enhanced efficiency likewise indicates the motor may run cooler, which can prolong its lifespan. So, while the preliminary expense of a three-phase motor and possibly establishing a three-phase power supply may be higher, the lasting operational savings and much better performance frequently make it a beneficial investment for demanding applications. The motor essentially does more work with less electrical energy. These electric motors require less input for the same output.