Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

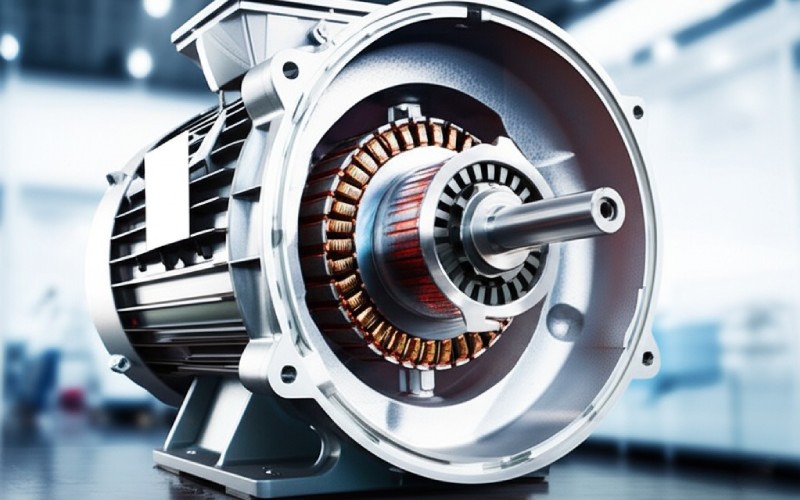

The stator core is a very vital part of an electrical motor . It helps the motor convert electrical energy into mechanical energy. This write-up will certainly damage down exactly what the stator core does. If you need to know how your motor truly functions, you are in the best place! It’s all about making the motor run well and save power.

The stator is the fixed component of the motor . Think about it like your house, and the rotor is the individual relocating within. The stator remains still. This stator is very important for any type of electric motor . It is among the vital parts that make the motor work. The stator is the set component of a motor . The stator itself has a couple of components. It has a framework, a stator core , and winding (cables). The stator is in charge of developing a magnetic field. This area is what makes the rotor spin. So, without an excellent stator , your motor simply will not do its work. The stator is the structure for the motor’s power. The stator plays a large role in just how the motor runs. The stator consists of these parts working together to assist the motor . The stator is one of the main parts.

Now, let’s focus on the stator core . The stator core is an important component of an electric motor . What is the primary feature of this stator core ? Well, its main feature is to provide a very easy course for the magnetic lines of force. Envision magnetic energy moving like water in a pipeline. The stator core is that pipe for the motor . This core assists to focus the magnetic field. The stator core is normally constructed from several slim sheets of metal, typically silicon steel . This core is a crucial part of the motor . The stator core’s task is likewise to hold the stator winding . The stator winding is constructed from coil cords. These cables are put right into stator slots in the stator core . So, the stator core acts as a strong assistance for the winding . It sees to it the coil wires remain in the ideal location. This aids the motor to create the magnetic field it needs to make the rotor rotate . The stator core is crucial for the motor’s structure and electromagnetic activity. The functions of the stator greatly rely on a good stator core . This stator iron core is central to motor procedure . The stator acts as this support.

This is where the magic occurs in lots of types of electric motors , particularly an ac motor ! The stator winding , held by the stator core , obtains an electrical present . When current circulations via the stator windings , it creates electromagnetic fields . In numerous motors , like a three-phase motor , this means the existing adjustments in the different components of the stator winding makes the electromagnetic field spin. This is called a rotating electromagnetic field . The stator core is crucial here because it overviews and enhances this area. The stator core assists to create a turning electromagnetic field extremely efficiently. Without the core , the electromagnetic field would certainly be weak and spread out. The stator core , being made from good magnetic material, makes the area strong and focused. This solid, spinning field is what draws the rotor around, making the motor shaft rotate . So, the stator core is a large assistant in turning electric energy right into activity. The stator and its core are developed to make this process smooth for the motor . The stator core plays a substantial function in this. This is a crucial function of a stator .

The reason is something called eddy currents. When an electromagnetic field adjusts in a metal core , it can develop tiny, swirling electric currents inside the core itself. These are eddy currents. The problem is, eddy currents produce heat and waste energy. This makes the motor much less reliable. This is what we call eddy current loss. The core experiences these losses. To combat this, the stator core is made of lots of thin slices of steel. These are called stator laminations or stator core laminations . Each lamination is covered with an insulating material. This suggests the lamination sheets are electrically separate from each other, even though they are piled firmly. This setup assists to minimize eddy current losses. By separating the course for the eddy currents, the motor lamination makes the motor far more reliable. We want to minimize eddy current losses as long as feasible. The stator core laminations also help reduce another kind of loss called hysteresis loss . So these countless steel laminations are very vital for the motor .

In an air conditioner motor , the stator and rotor resemble dance partners. The stator produces the music– the turning electromagnetic field . The rotor is the professional dancer that follows these songs. The rotor is the part that is totally free to turn . The stator has its winding and core , and the rotor likewise has its very own rotor core and usually a rotor winding or conductive bars. The magnetic field from the stator crosses the air gap between the stator and rotor . This field after that engages with the rotor . It makes the rotor wish to comply with the spinning area. This interaction produces torque , which is the turning force that makes the motor shaft rotate. So, the stator and the rotor collaborate very closely. One can not do its job without the various others in an electric motor . The stator engages with the rotor frequently while the motor is running. The rotor turns because of this. The duty of the rotor is to convert the magnetic force into activity. This communication within the stator and with the rotor is essential.

When an electric current (typically an alternating current ) streams via the stator windings of the stator , it establishes those magnetic fields we talked about. This existing is the lifeblood of the motor . The toughness and pattern of this present choose how solid the electromagnetic field is and how it acts. The stator core helps make this field solid. This electromagnetic field from the stator then connects to the rotor . If the rotor is the right kind (like in an induction motor or a synchronous motor), the area will certainly create forces on the rotor . In an induction motor , the stator’s area develops a current in the rotor itself. This brand-new existing in the rotor creates its very own magnetic field. These 2 fields– the stator’s and the rotor’s — press and pull on each other. This makes the rotor rotate and do work. So the current flows through the stator and indirectly makes the rotor rotate. The stator is responsible for this first step. The stator overviews this process.

Yes, it absolutely does! It’s intriguing because motors and generators are like 2 sides of the very same coin. An electrical motor takes electric power and turns it into power (spinning). A generator does the opposite. It takes mechanical energy (something rotating it) and turns it into electrical power . Both electric motors and generators make use of a stator and a rotor . In a generator , the stator and its stator core play a very similar role. The rotor is spun by an outdoors pressure (like a wind turbine). As the rotor (which commonly has magnets or its very own rotor winding with existing ) rotates, its magnetic field cuts across the stator winding in the stator core . This action produces a voltage and makes electrical present circulation in the stator winding . So, the stator core in a generator still guides the electromagnetic field and sustains the winding , but this time it’s to help generate electrical power, rather than consume it. The feature of a stator is critical in a generator too. The stator is one of the main parts in an electrical motor or generator . The stator makes certain the generator works appropriately.

Beyond assisting magnetism and holding the winding , the stator core has a couple of other works that help the motor and its motor lamination work well. One essential task is to offer physical strength and shape to the stator assembly. The stator core is part of the backbone of the stator . The stator may seem straightforward, but its core requires it to be strong. It has to sustain the stator core correctly. The stator core additionally assists to cool the stator core and the stator winding . Heat is a big enemy of electric motors . The lamination layout, while mostly for eddy current loss reduction, likewise has some impact on just how warmth moves with the core . Great motor layout makes sure there are methods for warm to run away from the stator core and winding . This helps the motor last longer and keep up far better performance and integrity . The stator core likewise adds to the overall performance of the motor .

If the motor stator core of your motor is harmed, it can create huge troubles. Possibly the motor overheated, or there was a mechanical shock. If the lamination sheets in the stator core are damaged– claim, their insulation breaks down and they begin touching each other electrically– then eddy currents can raise a great deal. This indicates more eddy current loss and hysteresis loss , which we call core loss . A healthy motor stator is essential. Increased core loss implies the motor obtains hotter than it should. This extra warmth can harm the insulation of the stator winding , causing shorts and motor failure. A damaged stator core can likewise make the motor loud and much less effective. The effectiveness of the motor will certainly decrease, implying it uses a lot more electrical power to do the same job. So, a healthy and balanced stator core is vital for good motor efficiency . A high-grade stator implies a great stator core . The stator core plays a vital duty .

The stator core laminations are a brilliant trick for boosting motor effectiveness . As IDYNAMIC, the stator core is usually made from thin sheets of silicon steel . Each lamination is coated with an insulating material. This is key for the stator . By using stator laminations rather than a solid iron core , we greatly reduce eddy current losses. These eddy currents resemble tiny whirlpools of electrical energy that do no beneficial work yet produce warmth. Heat is wasted power. So, by stopping these eddy currents with the insulated lamination layers, the motor wastes less power. This implies more of the electric power entering into the motor is converted into useful mechanical energy. This directly improves the motor’s power performance . This additionally helps in reducing hysteresis loss . A motor with a great stator core design will conserve you money on power. The stator is the fixed part that can conserve energy with its core style. –.

A1: The stator core is made of slim sheets of special steel, frequently silicon steel . These sheets are called stator laminations . Each lamination is coated with an insulating layer to reduce eddy current losses. This core is usually made by doing this for far better motor performance. The stator iron core requires great magnetic homes. This material assists the stator to do its work.

A2: While the basic function of a stator core is similar– to guide electromagnetic fields and sustain the stator winding — the exact layout can change. Different sorts of motors (like AC induction motors, DC electric motors , or synchronous motors) may have stator core designs maximized for their particular motor operation . The product and thickness of the motor lamination might also differ. The stator layout changes with the motor kind.

A3: The stator core itself does not directly establish the speed of the motor . The rate is a lot more pertaining to the frequency of the alternating current (for an air conditioner motor ) and the number of poles in the stator winding . Nonetheless, an excellent stator core aids the motor to run Warwickshireciently at its developed rate. If the stator core is damaged, it can influence performance of the motor and make it struggle to reach or maintain speed. The stator aids the motor achieve its speed by functioning well.

A4: Both are made from laminations to reduce losses. The stator core is part of the stator , the stationary part of the motor . It holds the stator winding that typically creates the primary magnetic field. The rotor core is part of the rotor , the part that turns . The rotor core offers a path for the magnetic field in the rotor and supports the rotor winding or conductor bars. The rotor core is made in a similar way, usually with rotor iron core laminations. The stator core and rotor core interact within the m