Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Have you ever looked at an electrical motor and wondered what’s inside? One of the most fundamental parts is something called stator core laminations. These are incredibly thin sheets of steel, like pages in a book. We use a lamination process to make them. This article is for you if you want to know what these laminations are. We’ll talk about the role of stator core components. You will find out why these special core laminations are vital for an excellent motor. Without them, your motor wouldn’t function well. It might overheat or waste a lot of power. So, let’s learn why every lamination counts!

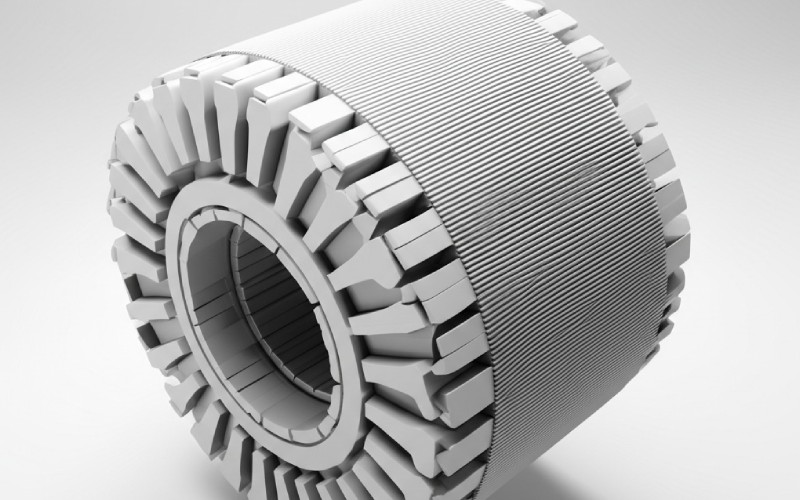

Consider an electrical motor. It has a component that remains still. That’s the stator. The stator cores are the core material of this stationary component. They are made from many thin metal sheets. These sheets are called laminations. These laminations are stacked together.

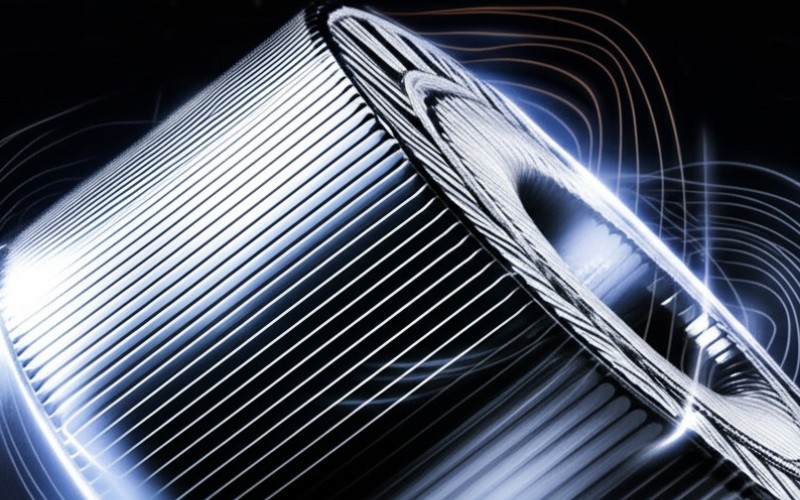

The function of stator parts, particularly the core, is to guide the magnetic flux. This magnetic flux is what makes the motor spin. So, the stator core requires efficient handling of magnetic flux. The way we make these stator cores using lamination is very clever. A stator lamination is a single thin sheet. Many of these make up the core lamination structure.

These stator cores also hold the winding. The winding is like coils of wire. Electrical current flows through this winding. This creates the electromagnetic field needed to run the motor. So, the stator core and its laminations work with the winding to make the motor go.

Using lamination for stator cores is a big deal. If we used solid metal stator cores, we would certainly have huge problems. A solid metal core would have way too many eddy currents. An eddy current is like a tiny swirl of electrical current inside the metal. These swirls make the motor hot and waste power.

So, the primary reason for lamination is to prevent these undesirable currents. Each lamination is a thin sheet. Each stator core lamination is coated with a thin insulating layer that doesn’t let electricity pass easily. This is called insulation. This coating helps to insulate one lamination from the next. This stops large eddy current flows.

This process of lamination helps the motor function better. It means less power loss. It also means the motor doesn’t get too hot as much. So, lamination is vital for a good, working motor. The lamination process itself needs to be very precise.

The main function of a stator core is to be a path for the magnetic flux. The stator core, made from many laminations, helps concentrate this magnetic flux. This concentrated power is needed for the motor to turn. This is a vital function of a stator core.

The stator core provides a solid structure. It holds the wires, or winding, in place. The main function of the stator core also includes helping to transform electrical energy into motion. Without a good core, the electromagnetic field would be weak and dispersed. The lamination helps make this field strong and well-directed.

Consider it like a racetrack for magnetic energy. The stator core lamination pieces direct this energy. This ensures the motor can do its job of generating rotational force. The main function of a stator core is to support this power conversion efficiently. This use of lamination is important.

Each lamination is a thin sheet. These laminations are stacked together. But they are not just ordinary metal sheets. Each stator core lamination is coated with an insulating material. This insulation is very important.

This coating prevents electricity from flowing easily between the laminations. So, when the magnetic field in the motor changes, it tries to create eddy currents. But because of the insulation on each lamination, these currents can’t become large. They stay as tiny, weak swirls within each thin lamination. This means less energy is lost as heat. This is how laminations reduce eddy currents.

So, the “magic” of stator core laminations is all about breaking up the paths for unwanted electrical currents. This helps the motor to stay cooler and use less power. The lamination design is a smart way to combat power loss. This method of using a lamination makes a huge difference.

Imagine you have a big block of Jell-O. If you try to shake it, the whole thing wobbles a lot. Now, imagine slicing that Jell-O into many thin pieces. If you shake these slices, they don’t wobble together as much. Motor lamination is a little bit like that for electrical currents in metal.

A solid metal part in a motor would let undesirable electrical currents, called eddy currents, swirl around a lot. This wastes energy. But if we make that part from many thin pieces—that’s lamination! Each slice, or stator lamination, is kept separate by a thin layer of insulation. This makes it difficult for large eddy currents to form.

So, motor lamination means making parts of the motor, like the stator core, from stacks of thin, insulated steel sheets. This lamination method helps the electrical motor run much better. It’s a simple idea, but it makes a huge difference in how well a motor works. The core lamination is crucial to this.

Stator core laminations address two big problems. The first one, as we’ve discussed, is eddy currents. These are undesirable electrical currents that flow in the stator core. They cause power loss and make the motor overheat. Laminations reduce eddy currents by breaking up their path. The thin design of each lamination helps a lot.

The second problem is called hysteresis loss. This happens because the electromagnetic field in the motor is constantly changing. The steel in the stator core gets magnetized and demagnetized over and over. This process of magnetization and demagnetization consumes some energy. This lost energy is hysteresis loss. The type of steel used for lamination, typically silicon steel (a type of electrical steel), helps to minimize hysteresis loss.

So, stator laminations are heroes! They combat eddy current losses and help in reducing hysteresis loss. This means the motor runs much more efficiently and doesn’t experience as much damage caused by overheating. A good lamination method is crucial.

Making these thin steel sheets for stator core laminations is quite a cool process. Initially, large rolls of special steel for laminations, like silicon steel, are used. This steel is chosen because it has good magnetic properties and helps reduce hysteresis loss.

Then, these sheets are cut into the ideal shape. This can be done with stamping dies. Think of it like a very precise cookie cutter punching out shapes from the steel. For very special shapes or small quantities, sometimes computer-controlled laser cutting machines are used. This computer-controlled laser cutting gives a very specific profile with exacting tolerances. Each lamination must be perfect.

After cutting, each lamination is often treated to add that crucial insulating layer. Then, many of these laminations—sometimes thousands of steel laminations—are stacked together very carefully. They might be welded, bonded, or held by interlocking features, or by methods like using keybars or clamping bolts to create a circular lamination stack. This forms the solid-looking but actually layered stator core. This lamination process creates a smooth and uniform surface.

When we talk about core lamination, the material is incredibly important. You can’t just use any steel. Often, a special type of steel called electrical steel is used. Adding silicon to steel changes its properties. It makes it much better at being magnetized and demagnetized easily. This helps to reduce hysteresis loss.

Sometimes, for very high-speed electric motors or special applications, other materials like cobalt or nickel alloys are used. These can be even better but often cost more. The main idea is to choose a material that has good magnetic properties and also helps lower those energy losses. The material for the lamination must be chosen very carefully.

And remember that coating on each lamination? That’s special too. It needs to insulate the laminations from each other. But it also needs to handle the heat from the motor and stick well to the lamination. This attention to detail in the lamination material and coating produces a high-quality stator.

The primary job of an electrical motor is to transform electrical energy into motion, or electrical energy into mechanical power. If a lot of that electrical energy is lost as heat, the motor isn’t doing a great job. This is where core lamination steps in.

By using stator core laminations, we significantly reduce eddy current losses. As these unwanted currents are reduced, less energy is wasted as heat. This means more of the input power goes into useful work—making the rotating shaft spin! This directly boosts the energy efficiency of the motor. The laminations play a huge role here.

Additionally, because laminations reduce heat, the motor can run cooler. A cooler motor often lasts longer. It also means the motor can sometimes be made smaller for the same amount of power. So, better performance and efficiency, longer life, and sometimes smaller sizes—that’s the power of good lamination! The careful work on each lamination pays off.

The role of stator core lamination is not just a little detail; it’s fundamental to how well an electric motor works. Without laminations, motors would be noisy, get very hot, and waste a lot of electricity. They would be very inefficient.

These thin layers, each stator lamination working together with its neighbors, are essential for controlling the flow of current and magnetic flux within the motor. They help reduce eddy currents and minimize hysteresis loss. This means less power loss overall. The lamination stack surrounding the stator winding is an essential component of the motor lamination design. It’s a complete circular or ringed layer when assembled.

So, the next time you see an electric motor humming along, remember those hidden stator core laminations. They are quietly doing their job, enhancing efficiency and ensuring the motor performs at its best. They ensure the magnetic field does its job without excessive difficulty. The lamination process allows for the production of these important parts, ensuring the rotor turns within a well-designed stator. Using lamination is a very clever engineering choice. These laminations play an essential role in reducing noise and improving power efficiency. Hysteresis loss, related to the material’s magnetization cycles, is also managed by the choice of lamination material. Every single lamination is important.