Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Let’s look inside an electric motor. These amazing devices are everywhere, from your washing machine to huge machines in factories. We’ll talk about the key components that make them work, especially the stator and the rotor. This article is worth reading because knowing about these parts helps you understand how so many things in our world move and work. It’s like learning the secret to a magic trick!

The job of an electric motor is to convert electrical energy into mechanical energy. Think about it: you plug something in (that’s electrical energy), and then something starts to spin or move (that’s mechanical energy). That’s an electric motor at work! It’s a real workhorse in our modern world.

These motors use the power of magnets to make things happen. When electric current flows through wires inside the electric motor, it creates a force. This force is what makes a part of the motor spin. This spinning part can then do work, like turning a fan or a wheel. It’s a clever way to convert one type of energy into another, more useful form for many tasks. The goal is to make things move, and an electric motor does this very well.

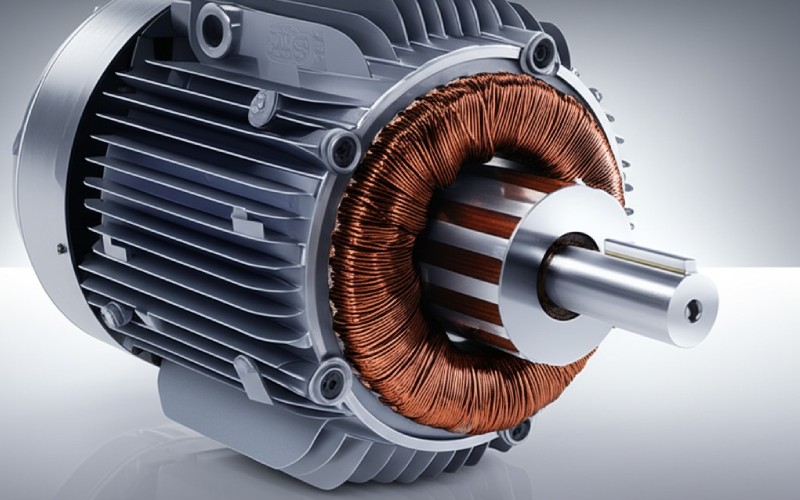

So, what’s inside these clever electric motor devices? While they can look different on the outside, most of them share some main components. The two biggest stars of the show are the stator and the rotor. These are the key components of electric motors. Think of them as the heart and soul.

Besides the stator and rotorThere are other important parts. There’s usually a shaft, which is the part that sticks out and spins. There are also bearings, which help the shaft spin smoothly. And in some types of motors, like DC motors, you’ll find a component called a commutator and sometimes a brush. Each component has a special job to do to make the electric motor run.

Let’s talk about the stator. The name gives you a clue: the stator is the stationary part of the electric motor. That means it doesn’t move. It stays put. The stator is the stationary part of the motor, and it’s a very important component. It usually forms the outer frame of the electric motor.

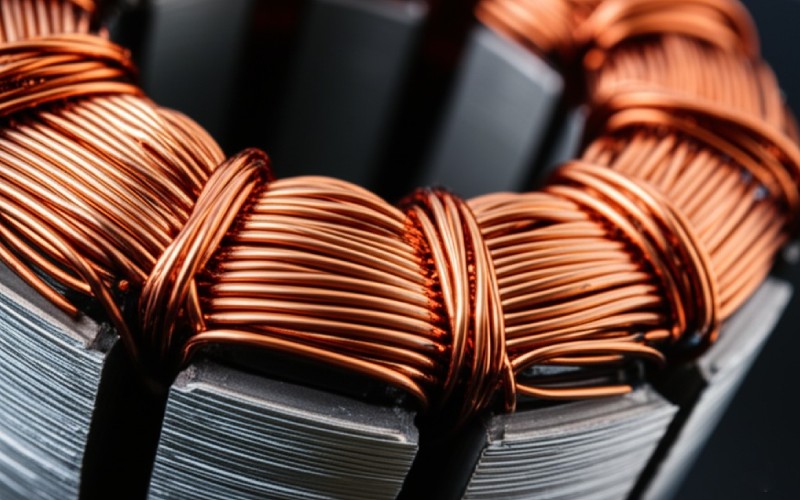

The main job of the stator is to create a magnetic field. This magnetic field is invisible, but it’s very powerful. The stator often has a core made of metal, specifically thin metal sheets stacked together, and wires wrapped around it. These wires are called the winding. When electricity flows through this winding, the stator becomes like a powerful electromagnet. Some high-efficiency stators are designed to make this magnetic field very strong with less loss of energy.

You might be wondering, “How does that winding on the stator actually make a magnetic field?” It’s a neat trick of science! The winding is usually made of copper wire, which is a good conductor of electricity. This wire is arranged in a coil or a series of coils, wound around parts of the stator core. Good insulation is used to keep the wires from touching each other where they shouldn’t.

When current flows through this winding, an electromagnetic field appears around the wires. Because the wires are coiled, this magnetic field becomes concentrated and strong. The design of the winding and the stator core helps to shape this magnetic field just right. This stator’s magnetic field is what will eventually interact with the rotor to make it spin. In an AC motor, the alternating current makes the magnetic field change in a way that keeps the rotor turning. The stator helps create the magnetic effect needed.

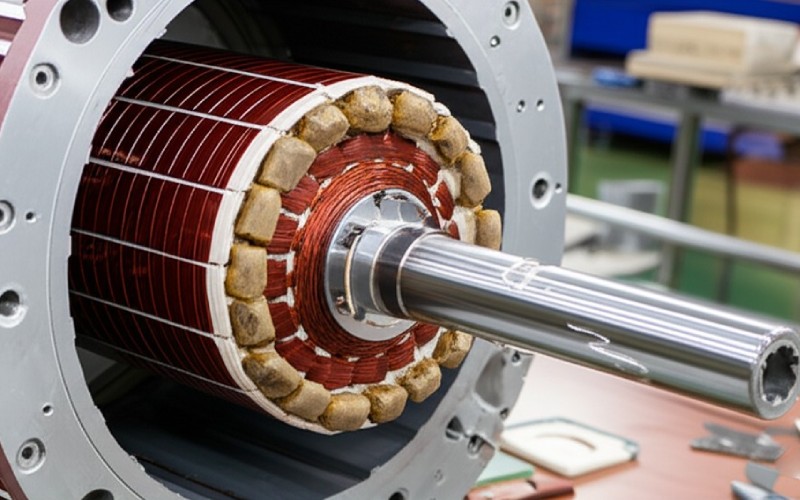

Now for the other star: the rotor. If the stator is stationary, what do you think the rotor does? You guessed it! The rotor is the rotating part of the electric motor. It’s the component that spins. The rotor is usually located inside the stator.

The rotor also has parts that react to the magnetic field created by the stator. In some electric motors, the rotor has its own set of windings, similar to the stator. In others, it might use permanent magnets or be made of a special metal that gets magnetized by the stator’s field. The job of the rotor is to catch the force from the stator’s magnetic field and use it to rotate. This rotational movement is then transferred to the shaft.

This is where the magic really happens! The stator and rotor are designed to work as a team. The stator creates its magnetic field. This magnetic field then pushes or pulls on the rotor, making it want to move. It’s like when you try to push the same ends of two magnets together – they push apart! Or when you put opposite ends together – they pull. The electric motor uses this idea.

The stator’s magnetic field interacts with the rotor to create a turning force called torque. This torque is what makes the rotor spin. As the rotor spins, the electric motor keeps changing the magnetic field (or the rotor’s connection to it) just at the right time to keep it going. This continuous push-and-pull between the stator and rotor is how the electric motor converts electrical energy into mechanical motion. The rotor to create motion is a key function.

You might not see it, but there’s a tiny space between the stator and the rotor. This space is called the air gap. The air gap is the distance between the inner surface of the stator and the outer surface of the rotor. It’s a very important part of the electric motor’s design, even though it’s just empty space!

This air gap has to be just right. If it’s too big, the magnetic field from the stator will have a hard time reaching the rotor strongly enough. This can make the electric motor less powerful and efficient. If the air gap is too small, there’s a risk the rotor and stator could rub against each other, which would cause big problems. So, engineers work hard to make this air gap the optimal size for good efficiency and performance.

We’ve talked about the spinning rotor and its shaft. But what helps it spin so smoothly and for a long time? That’s where bearings come in. A bearing is a component that supports the rotor and shaft, allowing them to turn with very little friction. You’ll usually find a bearing at each end of the shaft.

Without good bearings, the rotor would wobble, make noise, and wear out quickly. High-quality bearings are essential for a durable and reliable electric motor. They reduce friction, which means less energy is wasted as heat, and the motor’s parts last longer. Keeping the bearings in good shape is key to the longevity of any electric motor. They ensure the rotor can do its job effectively.

The core of the stator (and often the rotor) is made of thin metal sheets. These sheets are called laminations. You might wonder, “Why not just use a solid block of metal?” Well, there’s a very good reason for using lamination technology. It helps to reduce energy losses.

When a magnetic field changes quickly in a solid piece of metal, it can create swirling electric currents inside the metal itself. These are called eddy currents, and they cause loss of energy, mostly as heat. By using thin metal sheets, also called laminations, each coated with a layer of insulation, it’s much harder for these wasteful currents to flow. This makes the electric motor more efficient and helps prevent overheating. So, these laminations are a clever way to improve performance. We laminate the core to minimize these energy losses.

In some types of electric motors, especially DC motors (which run on direct current), you’ll find a special component called a commutator. The commutator is a ring made of metal segments, and it’s attached to the rotor’s shaft. It works together with parts called brushes. A brush is often a block of carbon that presses against the commutator.

The job of the commutator is to reverse the direction of electric current in the rotor windings at just the right moment. This reversal is needed to keep the rotor spinning in the same direction. As the rotor turns, different segments of the commutator connect with the brushes, changing the electrical circuit in the rotor. This action ensures that the magnetic poles created in the rotor (often called the armature in a DC motor) are always pushing and pulling correctly against the stator’s magnetic field to produce continuous torque. The commutator is a key part for this type of electric motor.

Now, let’s think about an industrial electric motor. These are the big, strong motors you see in factories and large machines. While they use the same basic principles of a stator and a rotor that we’ve discussed, they are built to be extra tough and powerful. An industrial electric motor needs to be durable and work for a long, long time, often under hard conditions.

In an industrial electric motor, every component, from the stator winding and lamination to the bearings and shaft, must be of high-quality. The insulation must withstand higher temperatures and voltages. The rotor and stator are designed for maximum torque and efficiency. Sometimes they have a sensor to monitor heat or speed for optimal operation. These motors are designed for reliability and durability because so many important jobs depend on them. They truly show how these key components of electric motors work together on a grand scale to convert electrical energy into mechanical energy. The rotors provide the powerful mechanical output needed.