Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

One thing that often puzzles folks is the heart of these motors: the stator and the rotor. More specifically, their lamination stacks. Understanding the difference between motor stator and rotor lamination stacks is super important. Why? Because these parts are key to how well an electric motor works. If you want to know how motors turn electrical energy into motion, or why they are built a certain way, this article is for you. I’ll break it down simply, so you can see what makes these critical components tick.

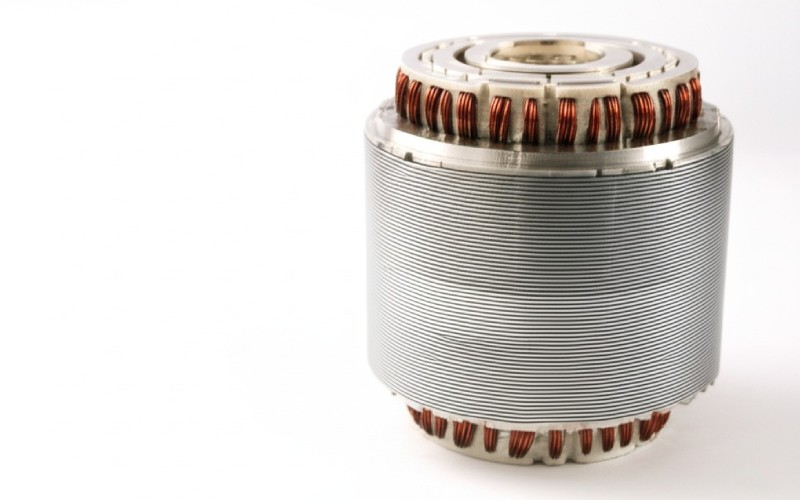

Think of the stator as the strong, still part of the motor. It doesn’t move. That’s why it’s called the stator, like stationary. The motor stator is usually the outer part of an electric motor. It has a very important job. It holds the winding of wires.

When electrical current flows through this winding in the stator, it creates a magnetic field. This magnetic field is super important. The stator’s job is to make this field just right. The stator lamination stack helps do this. These laminations are thin sheets of metal, often electrical steel, all pressed together to form the stator core. This stator core helps guide the magnetic field. The stator is the stationary part of the motor that surrounds the rotor.

The design of the stator lamination stack is very precise. Each lamination in the stator helps make the motor work better. The stator is a key piece. Without a good stator, the electric motor just won’t perform. The stator stacks are carefully built.

Now, let’s talk about the rotor. If the stator is the still part, the rotor is the part that spins. That’s easy to remember because rotor sounds like rotate. The motor rotor is usually found inside the stator. Its job is to respond to the magnetic field created by the stator. This interaction is what makes the rotor turn, giving us rotational motion.

The rotor also uses a lamination stack, often called a rotor stack or rotor core. Just like the stator, the rotor is made of thin lamination sheets. These rotor laminations help the rotor work well with the magnetic field. There are many types of rotor designs. Some have bars, some have magnets, but they all need to rotate smoothly. The rotor is the rotating part, and it’s crucial for the electric motor to do its job.

The rotor lamination stacks are two critical components along with the stator stacks in any electric motor. The rotor is made of these laminations to help control the magnetic paths and reduce energy loss. When the stator creates a magnetic field, the rotor wants to line up with it. As the magnetic field in the stator changes (like with alternating current), it keeps pulling the rotor around. This is how an electric motor works! The rotor is the moving part, a true workhorse.

We use lamination stacks to fight something called eddy currents. When a metal core is in a changing magnetic field (like in an electric motor), small, swirling electrical currents, called eddy currents, can form in the metal.

These eddy currents are bad news. They create heat, which wastes energy. They also create their own weak magnetic field that can fight against the main magnetic field we want. This means the motor is less efficient. So, we use laminations. A lamination is a thin sheet of electrical steel. These sheets stacked together form the lamination stack. Each lamination is often coated with a very thin insulating layer. This layer makes it hard for those eddy currents to flow between the lamination sheets.

By using a lamination stack, we greatly reduce eddy current losses. This makes the electric motor run cooler and use less electrical energy. So, those many layers in the stator lamination and rotor lamination are there for a very good reason. It’s a clever way to make motors and generators much more efficient. The laminated cores are a must for good motor performance.

Making stator and rotor lamination stacks is quite a process. First, you need the right material. This is usually a special type of electrical steel, often silicon steel. This steel alloy has good magnetic properties and helps keep energy losses low. The steel sheets are thin, sometimes thinner than a playing card.

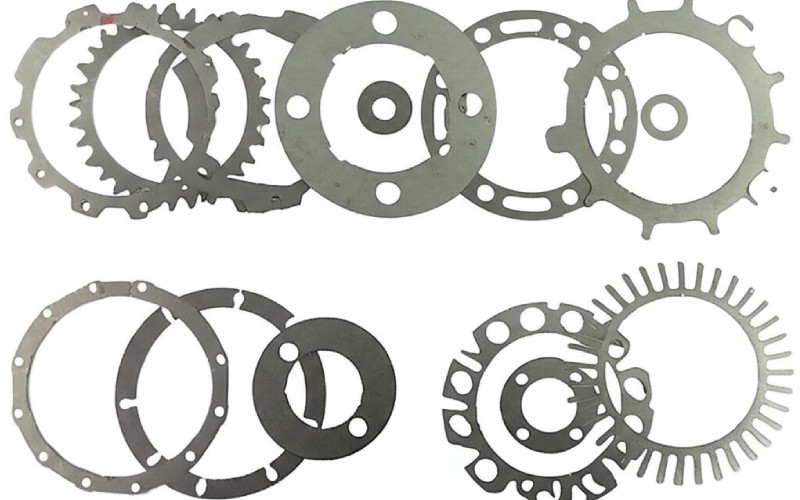

Next, these steel sheets need to be cut into the right shape for each lamination. There are a few ways to do this. For high-volume production, big machines stamp out the lamination shapes, like a cookie cutter. For smaller batches or complex shapes, they might laser cut the lamination. This gives very precise cuts. Each lamination for the stator will have slots for the winding, and each rotor lamination will have its own design.

Once all the individual laminations are cut, they need to be stacked up to form the lamination stack. This is where they stack cores. The laminations are placed one on top of the other to the right height. Then, they are often held together. Sometimes they are pressed tightly, sometimes they weld them on the outside edges, or use rivets or other methods. The goal is to make a solid core for the stator or rotor while keeping those insulating layers between each lamination. This is key for motor core lamination.

Okay, so both the stator and rotor use lamination stacks. But what are the differences between stator and rotor lamination designs? They have unique roles, so their lamination stacks are different too. The most obvious difference is often the shape and size. The stator lamination forms the outer, stationary part. It typically has slots on its inner diameter where the copper winding wires are placed. This winding carries the current that creates a magnetic field.

The rotor lamination stack, on the other hand, is built to rotate inside the stator. Its laminations are designed to interact with the stator’s magnetic field. For many common motors (like induction motors), the rotor laminations will have slots or bars, often made of aluminum or copper, embedded in them. These bars are what the stator’s magnetic field acts upon to make the rotor spin. The rotor stack needs to be strong to handle the spinning forces.

So, while both use the principle of lamination to reduce eddy current losses, their physical forms are tailored. The stator lamination is about creating a strong, stable magnetic field. The rotor lamination is about responding effectively to that field and turning. These significant differences mean you can’t just swap a stator lamination for a rotor lamination. They are designed as a pair: the rotor and the stator.

Let’s dig a bit deeper into the core of the stator and rotor. The lamination stack is the core. Whether it’s a stator core or a rotor core, its main job is to guide and concentrate the magnetic field. Think of it like a path for magnetism. Good magnetic properties in the core material are essential.

The stator core, made from stator lamination stacks, needs to efficiently carry the changing magnetic field produced by its winding. If the core material isn’t good, a lot of magnetic energy can be lost as heat, or the field might not be strong enough. The shape of the stator lamination and its slots are designed to make this magnetic field as effective as possible for interacting with the rotor.

The rotor core also needs good magnetic properties. It has to allow the magnetic field from the stator to pass through it and induce currents (in an induction rotor) or interact with magnets (in a permanent magnet rotor). The design of the rotor lamination stack helps define how the rotor will behave – its speed, its torque, and its efficiency. Both the stator core and rotor core are carefully engineered using specific types of lamination to achieve the desired motor performance.

The magnetic properties of the electrical steel used in stator and rotor laminations are a really big deal. We need a material that magnetizes easily but also loses its magnetism quickly when the current changes. This is especially true for motors running on alternating current.

The electrical steel used is often a special alloy, usually silicon steel. Adding silicon to steel changes its magnetic properties. It increases electrical resistivity, which helps to reduce eddy current losses even further. It also helps reduce something called hysteresis loss, which is another way energy can be wasted in the magnetic field of the core. The thickness of each lamination also plays a role; thinner laminations are better for higher frequencies.

So, the magnetic properties of the stator lamination and rotor lamination material directly impact how efficient the electric motor will be. Better magnetic properties mean less energy wasted as heat, a stronger magnetic field for a given amount of current, and overall better performance from the rotor and stator. This is why engineers spend a lot of time selecting the right grade of electrical steel for each lamination stack in the motor stator and rotor.

Most common electric motors are “radial flux” motors. This means the magnetic field travels radially – from the stator inward to the rotor, or outward. But there’s another type you might hear about: an axial flux stator (and rotor). In an axial flux motor, the magnetic field travels along the axis of the motor rotor – parallel to the shaft.

This means the stator lamination stack and rotor lamination stack look different. Instead of long, cylindrical stacks, you often see disc-shaped stator and rotor parts. The lamination in an axial flux stator might be wound from a continuous strip of steel, like a clock spring, or made from segmented pieces. The rotor in an axial flux design is also disc-shaped and faces the stator disc(s).

The main idea of using lamination is still the same: to reduce eddy losses. However, the way the stator and rotor lamination stacks are made and how they interact is different. Axial flux stator designs can offer benefits like a more compact shape (shorter and wider) and sometimes higher power density. They are used in applications like wind turbines for converting wind energy and some electric vehicles. It’s another example of how motor technology adapts the stator and rotor design for specific needs.

Having good capability for stator and rotor design and manufacturing is absolutely key. If the stator lamination stack isn’t made right, or if the rotor lamination stack is off, the whole electric motor suffers. These aren’t just simple metal parts; they are precision components.

Good design capability means you can optimize the shape of each lamination for the best magnetic field flow. It means choosing the right electrical steel for the job. It means figuring out the best way to make the lamination stack – whether to stamp or laser cut, how to insulate each lamination, and how to hold the stack together firmly. This affects the motor performance, its efficiency, how much noise it makes, and how long it lasts.

When companies specialize in laminations and stack cores, they develop this deep capability for stator and rotor parts. This is vital because even small mistakes in the stator lamination or rotor lamination can lead to big problems. Poorly made stator and rotor lamination stacks can cause overheating, vibrations, and reduced power. So, getting these motor core lamination parts right is a cornerstone of building a good electric motor. It ensures the rotor and stator work together perfectly.

This brings me to what happens when things go wrong with the motor stator and rotor lamination stacks. If the lamination stack isn’t properly designed or made, you’ll see problems. For example, if the laminations are too thick for the operating frequency, or if the insulation between them is damaged, you’ll get high eddy current losses. This means the motor gets too hot and wastes a lot of electrical energy.

If the stator lamination stack or the rotor stack isn’t held together tightly, the laminations can vibrate. This makes noise and can eventually lead to mechanical failure. If the wrong electrical steel is used, the magnetic properties won’t be good, and the electric motor won’t produce the power it should. The motor will not generate the torque it needs if the rotor and stator are not working in harmony due to lamination issues.

These stator and rotor lamination stacks are two critical components of any electric motor or generator. Ensuring high quality in the stator lamination and rotor lamination is not just a detail; it’s fundamental to the motor’s function. Properly selecting and maintaining electric motors, including their lamination stacks, is crucial for reliability. The intricacies of motor design, especially with stator and rotor laminations, make a big difference. These important parts of the motor need to be perfect.