Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Ever questioned what makes an electrical motor spin and do its task? A large part of the magic inside an electric motor is something called stator winding. This thorough guide is for you if you’re curious regarding just how a motor functions, or if you are just one of the novices in motor layout . We’ll discover the interesting distinction in stator winding techniques. You’ll see how the winding process for a stator is vital to electric motor power. This write-up deserves analysis because comprehending stator winding aids you comprehend the heart of nearly every electrical motor , from simple ones to sophisticated BLDC motor styles.

The stator is the component of the electric motor that remains still. Think about it as dealing with external components. Currently, the winding component describes cables, typically copper wire , that are wound right into coils. So, a stator winding is just a set of these wire coil setups put into the stator of an electric motor or generator . This winding is an important component of how the electric motor works.

These coil groups are thoroughly put and connected. The way this winding is wound helps develop a course for electrical power to flow. When electricity goes through this winding , it develops an electromagnetic field . This field is extremely important, as we’ll see. So, the stator winding is not just cable; it’s a thoroughly created set of coil components that helps the electric motor do its work. The number of winding beginnings and just how they are attached also plays a large function in the motor function.

You could be asking, “Okay, so there’s a winding in the stator . Why does it matter a lot for the motor ?” Well, it matters a great deal! The stator winding is where the magic starts for making a motor spin. When electricity flows through the coil in the stator winding , it produces an effective electromagnetic field . This isn’t simply any kind of electromagnetic field; in numerous kinds of motor , it’s a turning magnetic field .

This magnetic field from the stator winding after that “talks” to the rotor , which is the part of the motor that spins. This communication presses or draws the rotor , making it transform. This turning force is called torque . Without the stator winding producing this electromagnetic field , the rotor would not relocate, and the motor wouldn’t do any kind of work. So, the winding is essential to generate the power the electric motor requires. The style of the stator winding straight influences the electric motor ‘s speed, torque , and general electric motor performance .

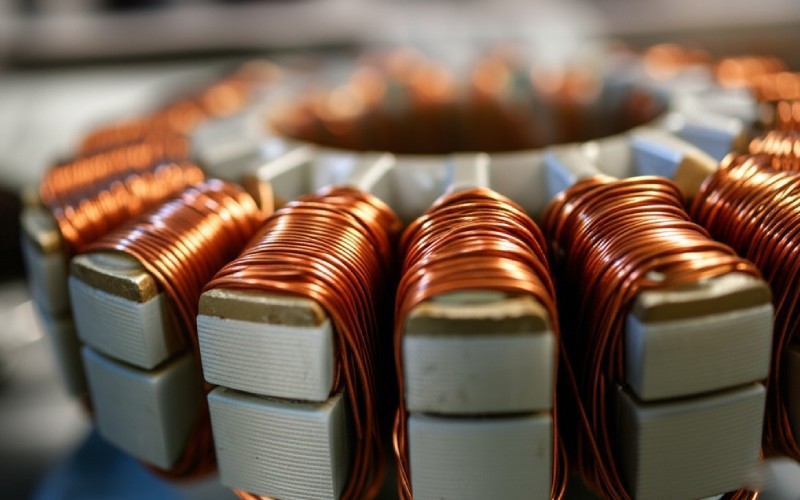

When we discuss the stator winding process , a couple of crucial parts are integrated. First, there’s the stator core . This is normally constructed from thin steel sheets called laminations stacked together. The lamination helps in reducing power loss. This stator core has slot openings in it. These slot areas are where the winding wires will certainly rest. The shape and variety of stator slot openings are very important for the motor design.

Next off, you have the actual winding wire . This is usually copper wire since copper is a terrific conductor of power. Prior to this winding wire being put into the stator slot , it requires insulation . Insulation is a finishing on the wire that maintains the electrical energy from shorting out between turns of the coil or to the stator core . We likewise use insulation materials to line the slot itself. This helps protect the winding and shield the motor . The top quality of the insulation is vital for a long-lasting motor winding .

Now, let’s discuss different means to do the winding . One common method is called focused winding. In a concentrated winding , each coil is wound around a solitary stator tooth, or a small team of stator teeth that form one magnetic pole . This suggests the winding is “focused” in detailed places on the stator .

This type of winding usually results in a shorter winding head — that’s the part of the coil that stands out from the stator core . Much shorter winding ends suggest much less copper wire is utilized, which can conserve cost and reduce electric resistance in the electric motor . Focused winding is typically located in BLDC motor layouts and some types of permanent magnet synchronous motors . It’s a popular choice for its simple winding structure .

An additional primary kind of winding is distributed winding . As the name recommends, this winding is “distributed” or spread out. Unlike focused winding where a coil kicks back one tooth, in a dispersed winding , the coil for each stage and pole is spread out throughout a number of stator slot openings. So, one winding group will certainly span numerous stator teeth.

One big advantage of a dispersed winding is that it can help develop a smoother, much more sinusoidal circulation of the magnetic flux in the motor air gap. This can lead to smoother motor procedure and reduce something called harmonic content, which can cause sound and resonance in the motor . This type of winding frequently enhances the overall motor performance.

The truth is, there’s no single “far better” one for every single motor . It really depends upon the specific motor design and what you require the motor to do. There are distinctions in stator winding approaches– some are much better for sure points.

Focused winding can be easier to produce and could make use of much less copper. This can be good for expense and in some cases for attaining high torque density in certain electric motor types. However, it can often lead to even more ripple in the torque . On the other hand, dispersed winding normally offers a smoother electromagnetic field and can boost motor performance and decrease noise. However, the winding procedure for a dispersed winding can be much more complex, and it may have longer winding overhangs. So, when picking a winding type, engineers think of price, efficiency, the desired flux path, and the specific demands of the electric motor application.

Yes, indeed! Besides concentrated and dispersed, winding can also be categorized by how many coil sides are put in each stator slot . This brings us to single-layer winding and double-layer winding . These terms define the winding layers inside the stator . It’s an additional interesting distinction in stator winding .

In a single-layer winding , each stator slot includes just one side of a coil . This indicates if you check out a slot , you’ll see conductors coming from just one winding or one phase group for that part of the electric motor . This kind of winding can be simpler to make. After that there’s double-layer winding . Here, each stator slot holds two coil sides. These sides can belong to various coils or perhaps various stator phases . Double-layer winding is very typical in many types of motor , specifically three-phase electric motors , because it offers a lot more versatility in the winding layout and can cause better electric motor qualities.

Ah, the BLDC motor ! That stands for Brushless DC motor . These electric motors are super popular currently, utilized in everything from drones to electric automobiles. The stator winding for a BLDC motor stator winding is really essential. Lots of BLDC motor styles make use of permanent magnet blades. The stator winding produces the magnetic field that interacts with these magnets to create torque .

You can locate both concentrated winding and dispersed winding in a BLDC motor . Concentrated winding is rather typical since it can cause a small motor and can be simpler to automate the winding procedure . This sort of winding can often bring about more “cogging torque ” (a type of jerky feeling at reduced speeds) in a BLDC motor , however designers have brilliant methods to decrease this. The option of winding substantially impacts the BLDC motor ‘s effectiveness, its torque result, and just how smoothly the electric motor runs. It’s a vital component of the BLDC motor stator winding layout.

Let’s discuss another type of winding you may find out about, particularly if you look inside the electric motor of older styles or details of DC electric motor kinds: lap winding. In lap winding , completions of each coil are linked to surrounding segments on the commutator (for DC motors). The coils themselves appear like they “lap” over each other as the winding proceeds around the stator or rotor core .

Lap winding is frequently made use of when you need an electric motor that can take care of high current however at a reduced voltage. One essential function of lap winding is that the number of parallel paths present in the winding is equal to the variety of posts in the electric motor . This winding framework is mainly made use of in DC electric motors and some kinds of AC motor or generator as well. The winding process can be a bit extra complex because of the variety of links needed for this winding .

When you get involved in motor design , the winding modern technology is a big location. An experienced electric motor developer considers a lot of things! The selection of winding — whether it’s concentrated winding , dispersed winding , single-layer , or double-layer winding — influences every little thing from motor efficiency to the manufacturing process . The winding design itself includes choosing the right winding wire size, the variety of turns in each coil , and how the number of windings are attached (like in a celebrity or delta arrangement for three-phase motors ).

Insulation is constantly crucial for any type of motor winding to prevent shorts and make certain the electric motor lasts. The approach of winding insertion into the stator slot is also essential for production. Exactly how the winding distribution is intended affects the magnetic field and the overall efficiency of the wound stator . Modern winding technology uses numerous winding options to maximize a motor for detailed demands, considering the power supply and application. These different kinds of windings provide a lot of flexibility. Getting the stator winding procedure right is crucial to an excellent motor or generator .