Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Particularly, what we make their cores from. Selecting the ideal material for an electric motor core is a truly large offer. It can change how well the motor works, how much power it uses, and even how much it costs to make. For a long period of time, steel laminate has actually been the king. And now, there’s an additional gamer: soft magnetic powder, typically called soft magnetic composite (SMC). We’ll check out lamination vs. powder for your motor design. We’ll see which may provide you much better efficiency or various other advantages. Allow’s go into this conventional vs. brand-new material choice.

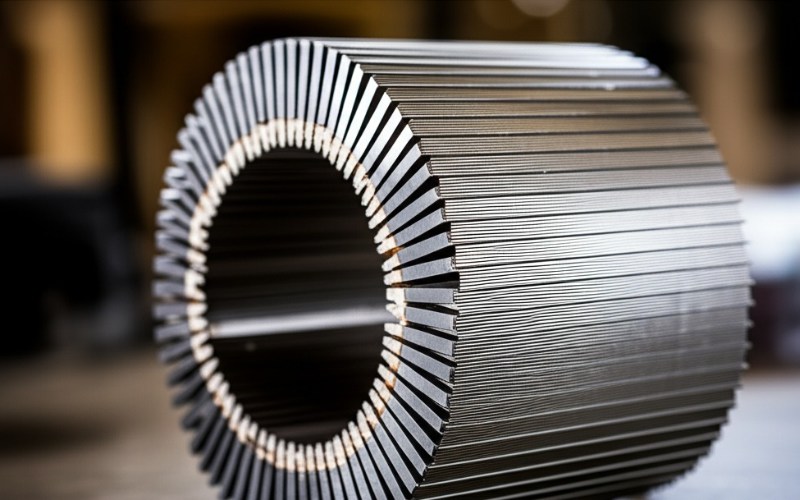

When we discuss an electric motor, there’s a key part inside called the core. This core is extremely essential because it assists to lead the electromagnetic fields. These fields are what make the motor rotate and do its work. The material we pick for this core makes a massive difference in the motor’s efficiency. For years, the primary option has actually been steel, specifically thin sheets of electric steel stacked together. This is what we call a lamination stack.

Currently, we have various other options. One interesting alternative is utilizing a special powder. This isn’t just any metal powder; it’s a soft magnetic powder. These powders belong to a group called soft magnetic composite products, or SMCs for short. The choice in between these electric motor core materials can affect every little thing from the motor’s size to its efficiency. It’s a huge decision in the design process.

You might ask, “Why fuss a lot about this element?” Well, the core material directly affects how much power your electric motor wastes. When a motor runs, some energy is lost as heat in the core. We call this “core loss.” A good core material will certainly decrease these losses. This means even more of the electrical power going into the motor is made use of to do real work. This makes the motor extra reliable.

Higher efficiency is a big bargain. For an electric vehicle, it means a lot more miles on a single charge. For factory machines, it implies reduced power costs. The best material can lead to a motor that runs cooler, lasts much longer, and offers far better performance. So, choosing the best core material is an essential step to maximize any kind of electric motor design. We require you to check out the properties of each material to see just how it aids.

For many years, steel lamination has been the requirement for electric motor cores. How it works is pretty brilliant. We take very thin sheets of special electric steel. Each sheet is coated with a slim insulating layer. After that, we stamp the shapes we need for the motor core and stack them up. This stack is called a lamination stack or laminated core.

The primary reason we utilize thin laminations is to fight against something called eddy current loss. These are small swirling electric currents that can appear in the core material when it’s in a transforming magnetic field. These currents develop warmth and waste power. By making the steel sheets slim and protected from each other, we decrease these losses. Lamination steel uses good magnetic performance and low flux leakage, especially for applications performing at lower frequencies like 50 or 60 Hz. It’s a proven material we comprehend effectively.

Currently, let’s speak about soft magnetic composite, or SMC. There are various means to make a motor core. As opposed to stacking steel sheets, we utilize a unique metal powder. Each little bit of this powder is covered with an electric insulator. After that, this powder is pushed into the exact shape needed for the motor element using a process called powder metallurgy. This can be a big advantage.

SMCs supply a special property: they are magnetically isotropic. This suggests they can bring magnetic flux equally well in all three dimensions. Typical laminations are fantastic for magnetic fields that flow primarily in two dimensions, along the plane of the lamination. However, for complicated motor layouts where the magnetic fields require to flow in all directions, SMC material can be a much better fit. This ability opens up new possibilities for electric motor layout and can help decrease the total weight of the motor.

The design process for an electric motor definitely adjusts depending on if you select lamination steel or SMC powder. With laminations, your layout is somewhat limited by the reality that you’re stacking 2D shapes. You need to think about exactly how to stamp these shapes with very little waste from the steel sheet and how the lamination stack will certainly be assembled. The internal design should account for the direction of the magnetic flux.

With SMC material, you have a lot more liberty to develop complex 3D shapes. This is due to the fact that you’re basically molding the powder right into the final form. This can cause more compact motor designs and can often integrate numerous parts right into a single SMC part. This can streamline assembly and decrease the number of parts in the system. However, the design needs to additionally consider the detailed mechanical and magnetic performance characteristics of the chosen SMC material. It’s a different method to consider just how the magnetics will certainly work in the motor.

One huge inquiry I commonly get has to do with loss reduction. Can SMCs really assist make an electric motor more efficient? The response is: it depends upon the application and the operating frequency. At low frequencies, like the 60 Hz we see in many household appliances, high-grade lamination steel commonly has lower core loss than SMCs. This is an important factor for numerous conventional motor kinds.

However, as electric motors are pushed to run at higher speeds and higher frequencies, specifically in things like electric vehicle traction motors or high-speed spindles, SMCs can begin to reveal their advantage. The little, protected powder particles in an SMC material are excellent at reducing eddy current loss at these higher frequencies. So, for certain high-frequency applications, an SMC design might attain better general efficiency and performance than a traditional lamination design. Research continues to advance SMC capabilities.

Powder metallurgy (PM) is the manufacturing process made use of to develop parts from metal powders, and this consists of SMC parts. I believe PM supplies some exciting opportunities for making much better motor components. One huge plus is waste decrease. When you stamp laminations from a steel sheet, you often end up with a lot of leftover material. With powder metallurgy, you use almost all the material because you’re pushing the powder right into the desired shape. This can reduce cost.

Additionally, powder metallurgy allows for the production of really complex shapes that would certainly be tough or impossible to make by stamping and stacking laminations. This can result in more optimized motor designs, possibly smaller and lighter motors with distinct magnetic circuits. While there are limits to the mechanical strength and magnetic permeability (or lower density/higher porosity) of some SMC products compared to solid steel, the advancement in PM technology and SMC material growth is shutting that space for numerous applications, specifically in the automotive field for electric motor parts.

When we compare the pure magnetic performance of lamination steel vs. SMCs, it’s not an easy “one is always much better” response. Lamination steel normally provides greater magnetic permeability. This implies it can carry magnetic flux more easily than numerous SMC products. It also commonly has greater saturation induction, meaning it can take care of more powerful magnetic fields prior to it “saturates.” This is a huge advantage for several motor layouts that need high torque.

However, SMCs shine in their 3D flux carrying capability and their performance at high frequencies. While their permeability might be lower, the capacity to design complex flux paths and the lower eddy current loss at high frequency can make them the better option for certain electric motor applications. The relative performance depends greatly on the motor’s operating problems and design goals. We are required to consider the data for each particular material and application.

Even with the rise of SMCs, traditional motor lamination technology isn’t stalling. There are several ways we can optimize a lamination stack for better electric motor performance. One essential area is the choice of lamination steel itself. There are numerous grades of electric steel, each with different properties and costs. Selecting the appropriate grade for the specific application can substantially reduce core losses.

An additional factor is the thickness of the laminations. Thinner laminations typically bring about lower eddy current loss, but they also increase the cost of stamping and assembly due to the fact that you need even more of them. The design of the lamination shape itself is also critical to guide the magnetic flux effectively and minimize undesirable air gaps or flux leakage. We also need to think about the stacking factor– how snugly the laminations are loaded– and the quality of the insulation between each lamination. All these details aid attain the most effective performance from a lamination-based motor design.

Finally, let’s discuss cost and manufacturing. For high-volume manufacturing of simple motor shapes, stamping laminations can be a very cost-effective process, despite having some material waste. The steel material itself is relatively inexpensive, and the stamping process is quick. The assembly of the lamination stack contributes to the cost, of course. This is a reliable manufacturing route with a great deal of existing facilities.

SMC components, used powder metallurgy, can offer cost savings in other ways. The SMC material itself can be more expensive per kilogram than lamination steel. However, the PM process can generate net-shape or near-net-shape parts, meaning very little material is wasted and fewer finishing steps are required. For complex designs, SMC can reduce the number of components and streamline assembly, resulting in lower overall system cost. The equipment required to compact SMC powder and the tooling cost are likewise critical factors. The best choice typically comes down to the specific motor design, production volume, and the target application. There is a growing need for this kind of material.