Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

If you have ever seen a 3D printer meticulously constructing an object layer by layer, or a robotic arm moving with fantastic precision, chances are a stepper motor was involved. A stepper motor is a special kind of electrical motor. It’s different because it moves in small, precise steps. This makes the stepper motor ideal for work where you require things to be in a very specific place. Think about it like a motor that can count its own steps!

In this post, we’ll check out the working principle of a stepper motor, which is exactly how it does its task. We will certainly also check out each type of stepper motor you might come across. Plus, we’ll discuss why a good motor driver is so essential for any kind of stepper. This is your friendly introduction to stepper motors. By the end, you’ll understand these brilliant tools much better, and you might even feel ready to make use of a stepper motor in your own fun projects. This article deserves reading because it makes understanding the stepper motor simple and clear.

What makes this stepper so special? Well, a stepper motor is a brushless electrical motor that converts digital pulses right into small, equivalent mechanical motions. Think of each pulse as a command telling the motor shaft to turn just a bit. The stepper motor is a type of synchronous motor. This means the rotor (the part that rotates) moves in sync with the magnetic field produced by the stator (the part that stays still). This design is vital to how a stepper motor operates.

This type of motor is fantastic because it doesn’t require a sensor to know its position. The stepper motor’s position is known just by counting the pulses sent out to it. So, if you tell a stepper to move 50 steps, it will certainly move exactly 50 steps. This makes the stepper motor really reliable for tasks that require careful control. This one-of-a-kind ability makes the stepper a favorite in many devices. This simple introduction to stepper motors shows why they are so valuable. The stepper motor is an electrical device that is very useful.

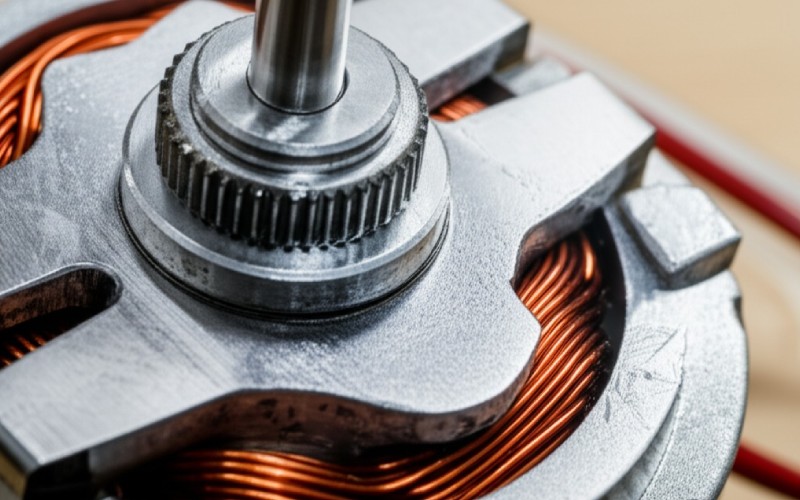

Now, let’s dive into the stepper motor working principle. It’s all about magnets! Inside a stepper motor, there are sets of coils. These coils are part of the stator. When electricity flows through a coil, it creates an electromagnetic field. The rotor, the part that spins, has teeth or permanent magnets on it. The motor works on the principle of these magnetic fields attracting and repelling the rotor. A stepper motor does not rotate smoothly like some other motors.

The motor controller sends out pulses of power to different coils in a particular order. Each pulse energizes a set of coils. This creates an electromagnetic field that pulls the rotor to a brand-new position. Then, the next pulse energizes another set of coils, and the rotor moves again, to the next step. This step-by-step movement is exactly how the stepper motor gets its name. The stepper motor transforms these electrical pulses right into precise rotational steps of the stepper motor shaft. It’s a brilliant system that gives the stepper great control.

You might ask, “Why is a stepper motor so efficient at hitting a specific position?” It’s due to how it’s designed and controlled. Each pulse sent to the stepper motor makes it turn by a fixed angle. This angle is called a step. The number of steps a stepper motor makes in one complete turn (360 degrees) is called its steps per revolution. For instance, a stepper motor may have 200 steps per revolution. This means each step turns the motor shaft by 1.8 degrees.

Since each step is a known, fixed amount, the stepper motor can move to a very accurate position simply by counting these steps. There’s no uncertainty. If your stepper motor needs to turn 90 degrees and it has 200 steps per revolution (1.8 degrees per step), the motor controller will send it 50 pulses (90 / 1.8 = 50). This precision, without needing intricate feedback systems, is a huge reason stepper motors are used in devices like 3D printers and CNC mills. The stepper delivers this precision consistently. This makes the stepper motor a reliable choice.

The three most common motor types of stepper are: the permanent magnet stepper motor, the variable reluctance stepper motor, and the hybrid stepper motor. Each type of stepper motor has its own method of working and its own strengths.

Understanding these types helps you pick the ideal stepper motor for your project. For instance, some stepper motors offer better speed, while others offer more power, known as high torque. The choice of stepper depends on what you need it to do. We’ll look at each of these stepper motor types more closely. This understanding is essential when working with any stepper.

Let’s talk about the permanent magnet stepper motor, often called a PM stepper motor. As its name suggests, this stepper motor uses a permanent magnet in its rotor. The rotor is the part of the motor that rotates. The stator, the part that stays still, has coils of wire, which are the motor windings. When electricity flows through these coils, they produce an electromagnetic field. This electromagnetic field interacts with the permanent magnet rotor.

The permanent magnet stepper motor works because the permanent magnet on the rotor is attracted to or pushed away by the electromagnetic field from the stator coils. By switching the electricity to different coils in order, the stepper motor makes the permanent magnet rotor turn step by step. These PM stepper motors are generally inexpensive and offer good torque at low speeds. The permanent magnet stepper is a common stepper. A permanent magnet is crucial to this stepper motor.

Next up is the variable reluctance stepper motor, or VR stepper motor (where VR stands for Variable Reluctance). This type of stepper motor is a bit different from the permanent magnet stepper. The rotor in a variable reluctance stepper motor is made from a soft iron material with teeth. It does not have any permanent magnets. The “reluctance” part means that the magnetic field prefers to go through materials that conduct magnetism easily, like the iron rotor teeth.

The working principle of a variable reluctance stepper motor involves the stator coils creating an electromagnetic field. The rotor teeth are then pulled towards the energized stator poles to find the path of lowest magnetic reluctance. By energizing different sets of coils in turn, the stepper motor draws the rotor from one step to the next. VR stepper motors can achieve very small step angles, but they usually have lower torque compared to a permanent magnet stepper motor or hybrid stepper motor. The variable reluctance stepper is another important stepper.

The hybrid stepper motor is a popular type of stepper motor. As its name suggests, a hybrid stepper combines the best features of both the permanent magnet stepper motor and the variable reluctance stepper motor. It uses both a permanent magnet and a toothed rotor. The rotor of a hybrid stepper motor usually includes a permanent magnet core, with two toothed iron cups (or end caps) at each end. The teeth on these cups are offset from each other.

This smart design allows the hybrid stepper motor to achieve small step angles, high precision, and great torque. The permanent magnet provides a constant magnetic field, while the toothed structure helps to guide the rotor with precision. The hybrid stepper benefits from permanent magnet and variable reluctance principles. Many stepper motors used in popular applications that require precision, like robotics and CNC devices, are hybrid stepper motors. This stepper motor is very versatile. The stepper is an excellent option.

So you have your stepper motor, but how do you make it move? That’s where the motor driver, specifically a stepper motor driver, comes in. A stepper motor driver is an electronic circuit that takes control signals, usually from a microcontroller (like an Arduino), and converts them into the power required to energize the coils of the stepper motor. You can’t just connect a stepper motor directly to a battery or a basic switch; it requires this special driver.

The stepper motor driver handles the intricate job of sending the right amount of current to the right coils in the proper sequence. This sequence is what makes the stepper motor turn step by step. Good stepper motor control is essential for smooth and accurate movement of the stepper. The motor driver can also control things like the motor speed and the current to the motor windings, which affects torque. Without a proper stepper motor driver, your stepper motor won’t function properly, or at all. This stepper motor driver is essential for the stepper.

You might be surprised by the number of places stepper motors are used. Their capability to provide precise position control makes them incredibly valuable. One of the most common applications of stepper motors is in 3D printers. The stepper motor moves the print head and the build platform with great accuracy. This is why 3D prints can be so detailed. Another big area for the stepper is CNC machines, which cut or sculpt materials based on digital designs.

Beyond these, stepper motors are commonly used in robotics for precise joint movements. You’ll also find a stepper motor in office equipment like printers, scanners, and photocopiers, moving paper and print heads. Even in medical devices, like automated medication dispensers or diagnostic equipment, stepper motors play a vital role because of their reliability. They are also used in automotive applications for things like controlling engine idle speed or adjusting mirrors. The variety of applications demonstrates how useful this stepper motor is. The stepper motor is truly everywhere!

They are both types of electric motor, but they work very differently and are used for different things. A simple DC motor typically spins continuously when power is applied. Its speed is controlled by changing the voltage, and its direction by changing the polarity. A DC motor is great for things like fans or toy cars where you just need continuous rotation.

A stepper motor, on the other hand, moves in discrete steps. It’s all about precise control of the motor position and rotation angle. A stepper motor is a brushless device, unlike many simple DC motors that have brushes. While some advanced DC motor systems can achieve precise control with feedback sensors, a stepper motor does this naturally. So, if you need to know exactly how much your motor shaft has turned, or move to a very specific location, a stepper motor is typically the better choice than a standard DC motor. These motor types serve different needs. The stepper motor excels at precision.

A: A stepper motor is an electric motor that converts electrical pulses into precise mechanical steps. Its main job is to control motion and position of the motor very accurately. This stepper is great for this.

A: A stepper motor knows its position by counting the number of electrical pulses it receives. Each pulse moves the stepper motor one step.

A: The three main types are the permanent magnet stepper motor, the variable reluctance stepper motor, and the hybrid stepper motor. Each stepper has its own design.

A: A motor driver (or stepper motor driver) controls the stepper motor by sending the right electrical pulses to its coils in the appropriate order. It allows you to control the motor’s speed and direction. This stepper motor control is critical.

A: It depends on the job! A stepper motor is better for applications that require precise positioning and controlled steps. A DC motor is usually simpler and less expensive for continuous rotation. The stepper motor is for precision.