Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Which motor should I use? Should it be a stepper motor? A servo motor? Or a brushless DC motor? Picking the wrong one can mess up your project. This guide will make things easy. I will tell you what I’ve learned to help you pick the right motor for your small machine. This will save you time and money. This article is a simple road to making your project work well.

Let’s start with the stepper motor. I often use a stepper motor for projects that need easy and exact control of its position. You can think of a stepper motor as a motor that moves in tiny, set distances. Each distance is a “step.” A full circle is made of many of these separate steps, perhaps 200 of them. This special way of moving is great for a lot of jobs. You can tell the motor to move a certain number of steps. It will then move to the right spot and stay there.

The great thing about a stepper motor system is how simple it is. You do not need a fancy sensor to report back its position. This is known as an “open-loop” control system. The controller trusts that the motor made every step it was told to. For a job that needs low speed and good power to hold its place, a stepper motor is often the best choice. The control is easy, the driver is simple, and the whole system costs very little. This makes the stepper motor a popular choice when you need to make a machine move on its own without spending a lot of money. The simple design of a stepper motor makes it something you can count on.

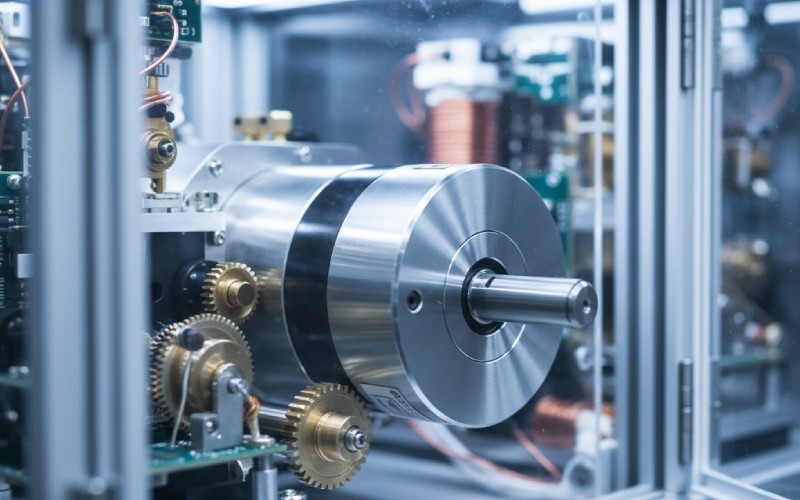

Now, let’s talk about the servo motor. I pick a servo motor when my project needs to be faster and more exact than a stepper motor can be. A servo motor is part of a “closed-loop control” system. This means it has a sensor that is called an encoder. This encoder sends back information to the controller all the time. This information, or feedback, tells the controller the motor’s exact position, its speed, and which way it is going. If the motor is not in the right spot, the controller will fix it immediately.

This feedback system makes a huge difference in many designs for machines. A servo motor can run at a very high speed and not get lost. It can also give a lot of turning power at any speed, from slow to fast. If your job requires fast and correct movements, a servo motor is the right choice. Imagine a robot arm that has to move fast and stop at an exact spot. A stepper motor might miss a step if the work is too hard, but a servo motor will know about the mistake and fix it. The control system is a bit more complex, but it works amazingly well.

The third motor on our top list is the brushless DC motor, also called a BLDC motor. I see a BLDC motor as a newer kind of motor that does not waste much power. A normal DC motor has little carbon parts that are called a “brush.” These brush parts get worn down after a while. A brushless DC motor has no brush. It uses smart electronic parts to send power to the right place in the motor. This makes the brushless DC motor very reliable, and it lasts for a long time. It can also run quietly for many, many years.

Because there is no brush to wear down, a brushless DC motor is great for jobs that need to run all the time without stopping. They are also very good at using power. This means they change more electricity into movement, and they make less heat. Being good with power is very important for gadgets you can carry that use batteries. You will often see a brushless DC motor in drones, electric scooters, and fans in computers. The control system uses sensors, like Hall effect sensors, to know where the rotor is. This lets the controller send power to the motor in the right way. A BLDC motor system can give you very smooth movement and high speed.

People often ask me about the big differences in the choice between a stepper and a servo. To make it easy to see, I made a simple table. This table shows the important points of each motor system side-by-side. Understanding these differences is an important part of picking the right motor for your design.

| Feature | Stepper Motor System | Servo Motor System |

|---|---|---|

| Control System | Open-loop, simple control. No feedback sensor. | Closed-loop control. Needs an encoder for feedback. |

| Speed Range | Best at low speed. Torque drops at high speed. | Works great across a wide range of speeds. |

| Torque | High torque at low speed and when stopped. | High torque across the full speed range. |

| Position Accuracy | Good, but can miss steps if overloaded. | Very exact and accurate. The system fixes errors. |

| Cost | Low cost for the motor and driver. | Higher cost for the motor, encoder, and controller. |

| Efficiency | Lower efficiency. Motor uses full power even when not moving. | High efficiency. Uses power only when needed. |

| Noise | Can be noisy and shake, especially at low speed. | Runs very smoothly and quietly. |

As you can see, the choice is based on your needs. For a simple job that does not cost much where you need to hold a position, the stepper motor is a great choice. For a fast-moving, high-speed job that needs very exact movement, the servo motor is the clear winner. The control needed for a servo motor is more advanced, but it gives you much better results.

Picking the right motor can seem difficult, but I have some advice to help you. You should start by asking a few key questions about your project. The answers will show you the best motor to use. You should first think about what your project really needs. The best way to succeed is to find a motor that fits your job perfectly.

First, think about the motion. What kind of movement do you need? Do you need spinning that does not stop, like for a wheel or a fan? A brushless DC motor is a great choice for that. Do you need to move to an exact spot or angle and stay there, like a pointer on a machine’s dial? A stepper motor is perfect for that. Or do you need fast and tricky movements that need to get up to speed quickly, like a robot that picks things up and puts them down? That is a job for a servo motor. The kind of movement is a very important part of picking the right motor.

Next, you have to look at speed and torque. How fast does your machine need to move? How much turning power, also called torque, does the motor need to have? Make a list of these things. If you need high torque but only at low speed, a stepper motor is a good choice that does not cost much. If you need high torque even when going very fast, you will have to look at a servo motor. A brushless DC motor can give a nice mix of speed and torque in a small size. It is important not to guess here. A motor that does not have enough torque will not work for your job.

Each motor type needs a special system to control it and talk to it. A stepper motor is the easiest one. It needs a driver. The driver gets simple step and direction signals from a main controller. Then it changes them into the electrical power needed to make the motor move one step. The information only goes one way. The controller tells the motor what to do, but the motor does not send any information back.

A servo motor system is a bit smarter. It needs a controller that can do more things. This controller gets a command to go to a spot. It then checks where the motor really is by using the information from the encoder. The controller then sends just the right amount of power to the motor to move it to the correct position. The communication goes both ways. This back-and-forth talk is why the servo motor is so exact. The system must have this communication to work.

A brushless DC motor also needs a clever controller. The controller has to know the position of the rotor to send power to the coils in the correct sequence. This is often done with Hall effect sensors that are inside the motor. The communication between the sensor and the controller helps the motor spin very smoothly. Some newer BLDC motor systems can work without a sensor. This makes the design of the motor more simple. The drive for this type of motor has to be a good partner for that specific motor.

When you build a system, you have to think about how much everything will cost together. The price of the motor is just one part of the total cost. I have seen many people pick a cheap stepper motor. Then they find out that putting the whole system together ends up costing more later on. You have to look at everything involved.

A full motion control system is made of a few parts. You have the motor, a driver or controller, a power supply, and the right cables. For a servo motor, you also need the encoder. Each part adds to the price. A stepper motor system is often the choice that costs the least at the start. The motor is cheap, and the driver is simple. But if it is not strong enough or fast enough, you might need a bigger motor or a gearbox. This adds more cost and makes the system bigger.

A servo motor system costs more to buy at first. The motor with the encoder inside of it is more expensive. The controller can do more, and it costs more as well. However, it could save you money in different ways. Because it uses power so well, you might be able to use a smaller power supply. Because it works so well, you might be able to build a faster machine that gets more work done. Putting the feedback device into the system is already done for you. When making a new machine, you must look at the total cost and see how well it works to make the best choice. Great companies like Anaheim Automation have a lot of different motor and control options to help. The choice has to be something you can afford.

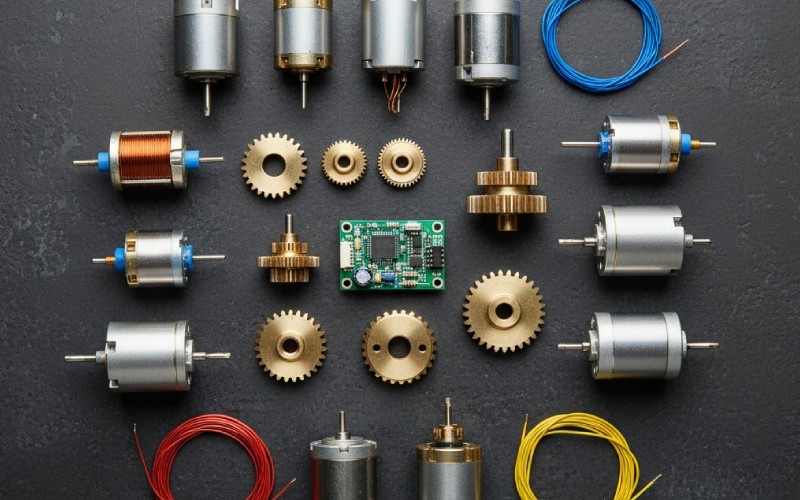

Seeing where each motor is used can make it easier to choose. Let me share some everyday examples of where they are used from my own work. These should help you see which type of motor could work for your project.

Here are some common jobs for each motor:

You have learned a lot. Now it is time to make a choice. Here are the last steps I suggest you take to pick the best motor. This easy process will help you make a good choice. You can follow this guide for your next automation project.

First, make a list of what your project needs to do. What is the most important part for your machine? Is it a low cost? Is it high speed? Is it very exact control over its position? Or is it a long life and using power well? Be truthful about what you really need. This list will be your guide. For example, if saving money is most important to you and speed is not, a stepper motor is probably your best choice. If being exact is the most important thing, you must look at a servo motor.

Second, figure out how much work the motor has to do. You need to know how much turning power and speed you need. How much weight does the motor have to move? How fast? How quickly does it need to get up to speed? These numbers are very important. Many companies that sell motors, like Anaheim Automation, have tools on their websites to help you find the right size of motor. This is a very important step to do. Picking a motor that is too small will make your project not work. Picking one that is too big will cost more and take up more space.

Finally, think about the parts that control the motor and what you know how to do. Do you feel good about using a simple control system? Or can you manage the adjustments for a closed-loop control system for a servo motor? The driver and controller are just as important as the motor. Make sure you pick a whole system where every piece works nicely with the others. A good company can sell you a motor and driver that are made to work together. This makes it much easier to put everything together.

In my experience, there is not one motor that is “the best” for every small machine. The best motor is the one that fits your special job perfectly. The stepper motor, the servo motor, and the brushless DC motor are all wonderful tools. Each one has its own special good points. Your job as a designer or engineer is to understand these good points and connect them with what you want your project to do.

I hope this guide has helped you understand the main differences. Remember to think about your whole system. The motor is only one part of the whole setup. The controller, the driver, and the power supply are important too. By thinking carefully about what you need for speed, torque, position control, and cost, you can feel sure about your choice. The right motor will help you build a better machine that you can count on more. Use what you learned here for your next project, and you will be on your way to making great projects that work by themselves.