Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Electromagnetic interference, or EMI, is like an invisible force that can mess with your electronics. It can cause all kinds of issues. In this piece, I will share 8 simple tips I have learned. These tips will help you lower or even stop EMI noise. These are simple tips that really work. You can use them in your own projects to make sure your signals are good and your electronics work the right way.

Electromagnetic interference (EMI) is electrical noise you do not want. It can mess with how your electronic devices work. You can think of it like hearing static on a radio. This problem can come from nature, like lightning. It can also come from things people make, like motors and power lines. The problems from EMI can be small glitches or they can make the whole system fail. It is a big deal that every engineer has to handle.

When you have EMI, it can mess up your data. It can make your gear not work right. And it can make your circuits unsteady. This bad signal can move through the air. It can also move along your power and signal cables. To fix EMI problems, you need to know where the EMI comes from and how it moves. After that, you can do things to lower it or stop it. This is where good ways of building things can help a lot.

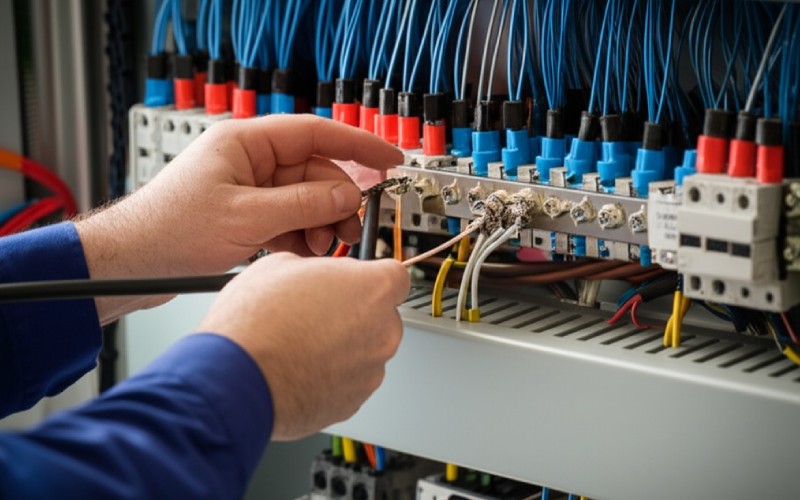

One of the best ways to fight EMI is to use shielding. A shield is like a wall that stops electromagnetic fields. You can think of it as a Faraday cage for your electronics. This shield could be a metal box. It could also be a special paint that electricity can flow through. The main point is to fully cover up your parts that are easily affected. This protects them from EMI that is outside. You also want to stop any EMI your own parts make from getting out.

You can use different kinds of materials for shielding. These include copper, aluminum, and steel. The material you pick should be based on the speed of the EMI you want to stop. For the shielding to work well, you have to be sure there are no holes or openings. Even a tiny hole can let EMI come in or go out. Using special gaskets and seals can help you keep your shield strong and solid.

| Shielding Material | Best For |

|---|---|

| Copper | Very good at conducting, great for many speeds of EMI. |

| Aluminum | Not heavy and costs less money. |

| Steel | Good for slow-moving magnetic fields. |

Good grounding is very important to lower EMI. Grounding gives an easy road for the electrical noise you do not want to flow away from your important circuits. A bad ground wire can make EMI problems even worse. It can make things called ground loops. These loops can work like antennas for EMI.

To make sure your ground is good, you should use a single-point grounding plan for your low-speed circuits. This means all of your ground wires go to one single spot. For high-speed circuits, it is often better to use a multi-point grounding plan. It is also very important to keep your ground wires as short as you can. This helps lower something called inductance. Using a big ground area on your circuit board can also help give a steady point and lower EMI.

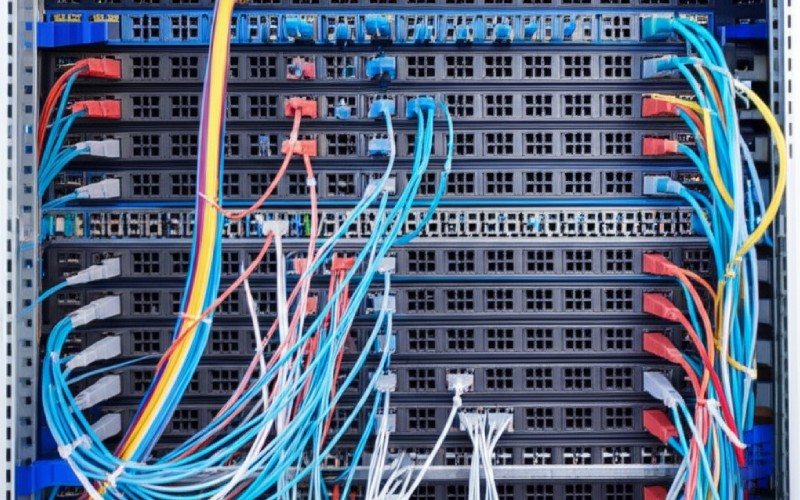

The cables you pick can make a big difference with EMI. Cables without a shield can work like antennas. They can pick up and send out electrical noise. This is why it is so important to use shielded cables, mostly for signals that are easily affected. A shielded cable has a special layer that works like a wall to stop EMI.

Here are a few tips about cables to help you lower EMI:

The parts you pick and where you put them on your circuit board can make a big difference in how well you fight EMI. Some parts, like switching power supplies and fast digital circuits, are big sources of EMI. It is a smart idea to keep these noisy parts far apart from your analog circuits that are easily affected.

When you are planning your circuit board, try to make the high-speed lines as short as you can. This will help make the loop smaller, which can work like an antenna. Using a solid ground area is also very important. It gives a simple return road for your signals and helps to lower EMI. Picking the right parts is also important. If you choose parts that do not make a lot of EMI, it can help you meet your EMC rules.

Power supplies can be a usual cause of EMI, mostly the switching kind. This is because they work very fast and can make a lot of electrical noise. This noise can then travel along the power lines and spread into the air. To handle this, you need to use filters where your power supply gets and sends power.

An EMI filter is a part made to stop high-speed noise. At the same time, it lets the power signals you want go through. A filter that is made well can lower a lot of the EMI that comes from your power supply. It is also a smart idea to use decoupling capacitors near your integrated circuits. These capacitors give a nearby boost of power and help to clear out high-speed noise.

Keeping parts separate is another important plan to lower EMI. You can do this by putting space between the noisy parts and the ones that are easily affected. You can also use shielding to keep parts apart. Another way is to use isolation transformers or optocouplers. These parts cut the electrical path between two circuits. This can help stop noise from one circuit from messing with another one.

When your design has both analog and digital signals, it is a good idea to have separate grounds for them. This can stop the noisy digital signals from messing with the sensitive analog signals. You can then join the two grounds together at just one spot. This method can make your system’s work and trustiness much better.

Transmitters are made to send out energy waves. This fact means they can be a source of EMI for other electronics that are close. To lessen these EMI problems, it is important to use an antenna that is made well. You also need to make sure the transmitter is working at the right speed and power level.

You should also think about where you put the transmitter and its antenna compared to where you put other sensitive parts. Keeping a good space between the transmitter and other electronics can help lower the chance of problems. You can also use shielding to keep the energy fields from the transmitter inside and to keep other devices safe.

As an engineer, there are a few design methods you can use to lessen EMI from the start. One important rule is to make the loop area of your wires that carry power smaller. A smaller loop will send out less electromagnetic energy. You can do this by putting the return road for a signal right under the signal line.

Another trick is to use something called differential signaling. This means you send a signal on two wires, one positive and one negative. The part that gets the signal then looks at the difference between the two signals. This method is really good at blocking common-mode noise, which is a big part of EMI. Using twisted-pair wires with differential signals can give you even better protection from noise.

The best way to make sure your design does not have EMI problems is to think about it right from the very start. Do not wait until your design is almost done to deal with EMI. It is much easier and costs less money to build for EMC (electromagnetic compatibility) from the beginning. This means you should follow good design habits like correct grounding, shielding, and putting parts in the right places.

It is also a smart idea to check your design for EMI. You can do this in a special room that is made to check for electromagnetic signals. By checking your design, you can find any possible EMI problems. Then you can fix them before your product is sold. This will help make sure that your product works well and follows all the rules.