Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

I’m right here to discuss 2 extremely essential sorts of AC electric motors: the synchronous motor and the induction motor. You may be asking, “What’s the largest bargain regarding an AC motor?” Well, I’ve found that knowing the difference between synchronous motor and induction motor kinds can truly assist you. It assists you pick the best motor kind for your demands. Stick with me, and I’ll make it very straightforward to see exactly how these synchronous and induction motors work. We will look at what makes each electric motor unique. This overview will certainly assist you comprehend the key distinctions in between synchronous and asynchronous motors (another name for the induction motor). We’ll check out the synchronous motor vs induction motors in a clear method.

Why keep reading? Since understanding these electric motors can conserve you money and time. Picking the best electric motor for the job is key. I’ll break down the synchronous motor and induction motor so any individual can get it.

Before we study the synchronous motor and the induction motor, let’s talk about an AC motor. What is it? An AC motor is a kind of electric motor. It uses AC, which represents alternating current. This type of current changes direction many times a second. I have actually seen these motors power numerous things, from fans to huge equipment. They are workhorses!

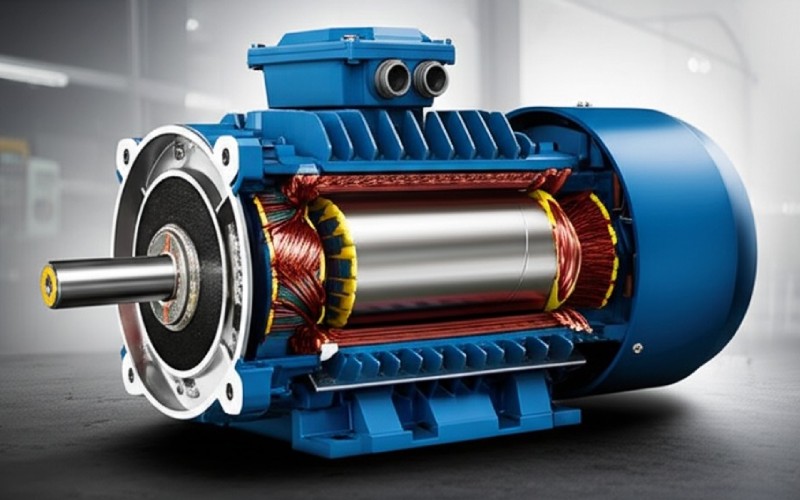

The major task of any electric motor, including an AC electric motor, is to convert electrical energy into mechanical energy. This indicates they take power from the wall outlet (or another AC source) and use it to make something spin or move. Both the synchronous motor and the induction motor are kinds of AC motors. They both have a fixed part called a stator and a spinning component called a rotor. The method these components collaborate is where we begin to see the distinctions between synchronous and induction motors.

Now, allow me to take a look at the induction motor. The induction motor is one of the most common types of AC motors available. It’s simple and tough. An induction motor is an AC motor. An awesome thing to recognize is that an induction motor is additionally sometimes called an asynchronous motor. Why “asynchronous”? “Asynchronous” implies “not at the same time.” This is because the rotor of an induction motor does not revolve at the exact same speed as the rotating magnetic field inside the motor. The rotor speed is always a little bit lower than the synchronous speed. This small difference in speed is called “slip.”

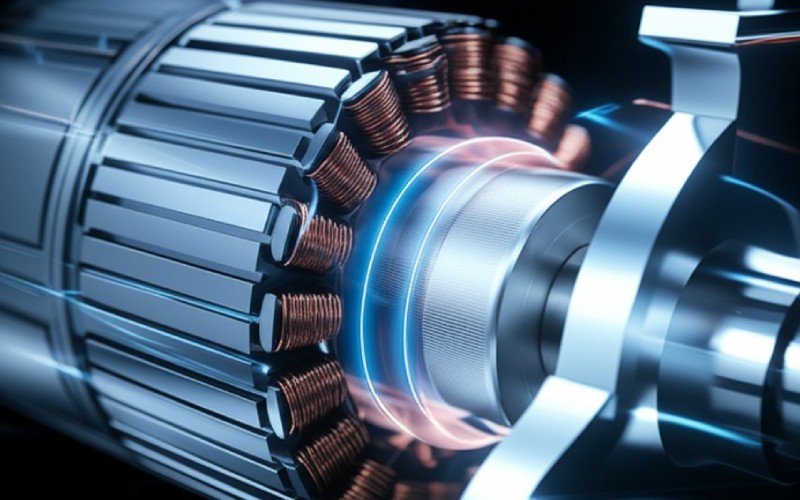

The induction motor works due to something called electromagnetic induction. This is a fancy way of saying that the stator (the outside component) produces a rotating magnetic field when AC power flows via its stator winding. This field then induces a current in the rotor (the inside component that rotates). This current creates its own magnetic field, and the rotor starts to turn as it attempts to catch up with the stator’s magnetic field. Many induction motors make use of a squirrel cage rotor, which is simple and robust. The induction motor runs extremely reliably. This motor is an AC motor that’s a genuine workhorse.

Successive is the synchronous motor. This motor type is additionally an AC motor, similar to the induction motor. But below’s the large difference between synchronous and other AC motors: a synchronous motor performs at a constant speed. This speed is called the synchronous speed. The rotor of a synchronous motor locks in with the rotating magnetic field made by the stator. So, it rotates at the exact same speed. No slip here!

To make this occur, the rotor in a synchronous motor requires its own magnetic field. This field can originate from permanent magnets (making it a permanent magnet synchronous motor) or from a DC excitation current fed to a rotor winding through slip rings. This means synchronous motors require a little bit more to start. The synchronous motor is an AC motor that operates with precise speed. I have actually seen synchronous motors used where exact speed is incredibly crucial.

Let’s speak about the parts that spin: the rotor. The rotor is vital to just how both an induction motor and a synchronous motor work. They both have a stator, which is the part that stays still and has windings to create a magnetic field when AC power is on. However the rotor designs are quite different. This is a large component of the difference between synchronous motor and induction motor designs.

In a lot of induction motors, the rotor of an induction motor is a squirrel cage rotor. Imagine a hamster wheel constructed from metal bars. These bars are short-circuited by end rings. There’s no electrical connection from the outside to this rotor. The current in the rotor is induced by the stator’s magnetic field. It’s simple and robust. A wound rotor induction motor is another kind, where the rotor has windings like the stator, attached to slip rings. This enables some control over speed and torque.

The rotor of a synchronous motor is different. It needs to have its own magnetic poles that do not transform. So, the rotor in a synchronous motor might utilize permanent magnets. This is common in a permanent magnet synchronous motor. Or, it can have a rotor winding that gets DC power through slip rings and brushes. This produces a fixed magnetic field on the rotor. This field locks with the stator’s magnetic field, making the rotor rotate at synchronous speed. The stator and rotor operate in perfect sync.

Starting an induction motor is typically quite straightforward. When you apply AC voltage to the stator winding of an induction motor, the rotating magnetic field is established. This field induces a current in the rotor, producing torque, and the rotor begins to rotate. Many induction motors, especially the squirrel cage type, are self-starting. They develop their torque quickly. Some larger induction motors may need special starters to restrict the starting current, but the standard principle is uncomplicated.

A synchronous motor, on the other hand, commonly requires a little bit more aid to start. A pure synchronous motor does not produce starting torque by itself if you just apply AC to the stator and DC excitation to the rotor at the exact same time. The rotor can’t catch up immediately. So, many synchronous motors have an added winding on the rotor, like a squirrel cage winding. This allows the synchronous motor to launch like an induction motor. Once it gets close to synchronous speed, the DC excitation is applied to the main rotor winding, and the rotor pulls right into sync with the rotating magnetic field. Synchronous motors call for this careful starting.

One of the largest crucial differences between synchronous and induction motors is their speed. As I stated, an induction motor is an asynchronous motor. This means its rotor always spins a bit slower than the rotating magnetic field from the stator. This speed distinction, or “slip,” is required for the induction motor to generate torque. The more load you place on an induction motor, the more the slip boosts, and the speed of the motor (induction motor speed varies) reduces a little.

A synchronous motor, however, performs at synchronous speed. This means the rotor transforms at the precise same rate as the stator’s magnetic field. There is no slip in a synchronous motor when it’s running normally. The synchronous speed is established by the frequency of the AC power and the variety of poles in the motor. If you need a constant speed that does not change with load, a synchronous motor is your buddy. This is a key point in the synchronous motor vs induction motor discussion.

Torque is the turning force of the motor. Both induction motors and synchronous motors generate torque to do work, yet just how they do it and their qualities differ. An induction motor generates torque when there is slip. The starting torque of a basic squirrel cage induction motor is good. The torque of an induction motor lowers if the voltage drops.

Synchronous motors can produce good torque. An interesting feature of a synchronous motor is its power factor. The power factor of a synchronous motor can be readjusted by transforming the DC excitation to its rotor winding. It can be made to go for a leading, lagging, or unity power factor. This is a big plus. Induction motors, on the other hand, constantly run at a lagging power factor. This suggests they draw reactive power, which isn’t always perfect for the power system. Motors have higher efficiency when the power factor is good. So, if power factor correction is very important, a synchronous motor uses an advantage.

So, when should you opt for an induction motor? Induction motors are widely utilized in many places. Because they are simple, robust, and commonly less expensive, induction motors are wonderful for general-purpose tasks. Think about followers, pumps, conveyors, and many factory equipment. The induction motor is a workhorse. There are different kinds of induction motors, like the squirrel cage induction motor (most usual) and the wound rotor induction motor (for special speed/torque control).

If you do not require specific, constant speed, and if a slightly lagging power factor is fine, an induction motor is typically the best choice. They are easy to keep because the rotor of an induction motor (particularly the squirrel cage kind) has no brushes or slip rings (unless it’s a wound rotor type). Induction motors are one of the most common types. The induction motor is an incredibly popular AC electric motor. It deals with the concept of electromagnetic induction. This induction motor (or induction machine) is everything about being reputable. A three-phase induction motor is extremely common in industry.

Now, when does a synchronous motor make more sense? A synchronous motor shines when you require constant speed, no matter the load. Think about points like clocks (older types), timers, and precision equipment. Additionally, since you can regulate the power factor of a synchronous motor, they are utilized in big plants to aid enhance the overall power factor of the system. This can save cash on electrical energy costs. Synchronous motors are used for these unique jobs.

The Permanent Magnet Synchronous Motor (PMSM) is a unique kind of synchronous motor. It uses permanent magnets in its rotor, so it doesn’t need DC excitation or slip rings. This makes the permanent magnet synchronous motor extra effective and smaller for its power contrasted to induction motors or other synchronous motor kinds. Permanent magnet synchronous motors are obtaining incredibly popular in things like electrical autos and high-efficiency home appliances. Motors provide power, and these do it well. The electric motor always runs at synchronous speed.

When picking an electric motor, upkeep is something I always think of. Standard squirrel cage induction motors are normally very low maintenance. The rotor has no wear parts like brushes. Synchronous motors that require DC excitation with slip rings and brushes will certainly require more care. The brushes can wear out and require changing. Nevertheless, a permanent magnet synchronous motor does not have brushes, so its upkeep is a lot more like an induction motor.

Regardless of the motor type, the quality of its components is key for a lengthy life. This includes the motor cores. The stator and rotor are made of slim steel sheets called laminations. A good electric motor core lamination manufacturer ensures these parts are made well. This assists the motor run efficiently and lasts much longer. Great motor cores indicate less power squandered as heat. This is true for both an induction motor and a synchronous motor. It is essential to convert electrical energy into mechanical work efficiently.