Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Electric vehicles are so quiet and fast. They also seemed very simple to me. The kind of motor in an electric vehicle is like the car’s heart. It affects how the car drives, the distance it can travel, and even its price. I have spent many hours studying these motors. Now, I want to tell you what I have learned. This article will explain the four main kinds of electric motors in electric vehicles. You will find out what is special about each one. After reading, you will understand your electric vehicle much better.

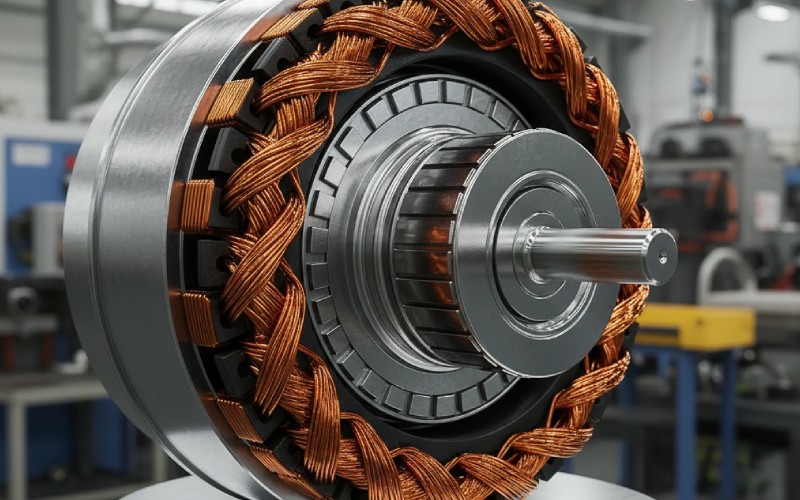

Let’s begin with the simple facts. An electric motor is a device. It uses electricity to create movement. In an electric vehicle, this movement is what makes the wheels spin. It takes the place of the internal combustion engine that you find in cars that use gas. An electric motor is different from a gas engine. It gives you instant torque. This means as soon as you push the pedal, the car speeds up right away.

The kind of motor in an electric vehicle is very important. The way the motor is designed changes the vehicle’s efficiency. It also changes its power and its weight. Some motors are very good at giving a lot of power. Other motors are made to be very efficient. This helps the car travel a longer distance on one battery charge. The kind of motor you choose affects how it feels to drive the car. When you understand the various types of electric motors, you know why one vehicle can feel so different from another. The motor is the main part of the system that moves the car forward.

A long time ago, I used to play with electronics. That’s when I learned about the simple brushed DC motor. This is a very old kind of electric motor. It works with a part called a brush. The brush sends power to the rotor, and the rotor is the part that spins around. The rotor has coils of wire called windings. When electricity goes through these windings, it makes a magnetic field. This field pushes against the stator, which is the part that doesn’t move. This push makes the rotor spin. A part called a commutator helps the rotor keep spinning.

Brushed dc motors are simple, and it’s easy to control their speed. But they have a big problem. The brush wears out over time. This means you have to fix or replace it. Because of this, you will not see this DC motor in new electric vehicles from big car companies. They are sometimes used in smaller, home-made EV projects or very light electric vehicles because they are not expensive. But for a normal-sized car, their limited speed and need for repair make them a bad choice.

The brushless DC motor (or BLDC motor) is much better than the one with brushes. Just like its name says, this motor has no brush. It uses smart electronics to change the direction of the magnetic field in the stator. This makes the motor last longer and use less energy. I have noticed these motors are a very good option. They need less repair work because they don’t have parts that wear out easily. This brushless design is an important feature.

BLDC motors have good power density. This means they can create a lot of power but are still small and light. They give you good turning power (torque) and they do not waste much energy. You can find this brushless DC motor in smaller electric vehicles like scooters, e-bikes, and some small cars. Their features make them a good choice for many uses. These bldc motors are known for working well and are a popular motor type for many things.

The AC induction motor is very strong and dependable. I was amazed to learn that Nikola Tesla invented this type of motor more than a century ago. An induction motor is special. It does not have a permanent magnet on its rotor. Instead, it uses a spinning magnetic field in the stator. This field creates an electric current in the rotor. This current makes a second magnetic field. When the two magnetic fields work together, they make the rotor turn.

This kind of motor is famous for being very tough and long-lasting. It is also cheap to make. Since it doesn’t use magnets, the company doesn’t have to worry about the high price of special materials. The well-known Tesla Model S used an induction motor when it first came out. These AC induction motors are very strong and can make a lot of torque. But, they can waste a little more energy at slow speeds when you compare them to other motor types. The simple design of the rotor and stator means they are made to last a long time.

These days, most new electric vehicles have permanent magnet synchronous motors (PMSM). I think this is the best technology for moving an EV forward at this time. This synchronous motor has strong permanent magnets on its rotor. The stator makes a spinning magnetic field. The rotor’s permanent magnet follows this field. It spins at the exact same speed. That is why we call it a synchronous motor.

The biggest reason PMSMs are so well-liked is because they are very efficient and have a high power density. The rotor already has a magnetic field from its permanent magnet. So, the motor does not need to use more electricity to make one. This makes the motor very good at saving energy. This means the vehicle can go a longer distance. The pmsm motors also have amazing torque density. This gives the vehicle very good performance. Many popular electric vehicles from brands like Chevrolet, Hyundai, and even new Tesla models use permanent magnet synchronous motors.

The switched reluctance motor (SRM) is a very interesting choice. I think of it as a less-known option for electric vehicles. Like an induction motor, a switched reluctance motor does not have permanent magnets. The rotor is just a simple piece of steel that has bumps, like teeth. The stator has windings. A computer sends little bursts of electricity to certain windings at the perfect moment. This pulls the rotor’s teeth to the powered-up part of the stator. This action makes the rotor spin.

The best things about an SRM are that it is very cheap and built strong. The rotor has no windings or permanent magnets, which makes it cheap and tough. But, they do have some problems. SRMs can have a problem with uneven torque. This can cause them to shake or make a lot of noise. To make them run smoothly, you need very smart and complex power electronics. Some companies are looking at the switched reluctance motor for cars, but it is not common in electric vehicles today because of the noise and the difficult controls. The srm design is simple, but controlling it is not.

It is helpful to look at the different kinds of motors used next to each other. Each type of motor has good points and bad points. A car company has to think about the cost, the performance, and the efficiency. They must find a good balance when they pick a motor for a new electric vehicle. The choice of motor type is very important for the vehicle.

Here is a simple table to compare the four main electric motors used in electric vehicles:

| Motor Type | Efficiency | Power Density | Cost | Maintenance |

|---|---|---|---|---|

| Brushless DC (BLDC) | Good | Good | Medium | Low |

| AC Induction Motor | Good | Medium | Low | Very Low |

| Permanent Magnet (PMSM) | Excellent | Excellent | High | Low |

| Switched Reluctance (SRM) | Fair | Medium | Very Low | Very Low |

As you can see, the permanent magnet synchronous motor (PMSM) gives the best results for saving energy and giving power. But it has a higher cost because of the expensive materials for the permanent magnet. The AC induction motor gives a good mix of solid performance and a lower price.

It’s always interesting to see what the big car companies are doing. Looking at which motors they use in their electric vehicles tells us a lot about the technology.

The pattern I see is that more companies are using permanent magnet motors (PMSMs). They do this because these motors perform better, especially as companies work hard to get the most driving distance possible from their batteries. The high torque from pmsms gives cars great speed right from the start.

People ask me this question often. And the real answer is this: there is not one single “best” motor for everything. The best kind of motor changes based on the main goal for the car. If a company wants to make an electric vehicle that is simple and does not cost much, they might look at an induction motor or maybe an srm later on. The lower cost of an induction motor can make the whole vehicle cheaper to buy.

But, if the plan is to make a car that can go the farthest distance and speed up the fastest, then permanent magnet synchronous motors (pmsms) are the top choice right now. The high power density of a pmsm means you can get more power from a smaller and lighter electric motor. This helps make the whole vehicle lighter and better at saving energy. So, the “best” motor is a balance between price, how well it works, and how much energy it saves for a certain electric vehicle. The motors use different kinds of technology to make the car move.

When I think about the future, I see many exciting new ideas for electric motor technology. The main problem with the popular permanent magnet motors is that they need special materials called rare-earth metals for the permanent magnet. These materials can cost a lot of money. It can also be hard to get them. For this reason, many companies are creating new motor designs. These designs use fewer magnets, or no magnets at all. But they still try to keep the high efficiency and high power that a PMSM has.

We may also see better versions of the switched reluctance motor (srm). They might have better control systems to make them quieter and smoother. We might also see new kinds of synchronous motors that do not need expensive magnets to work. The main goal never changes. It is to make the electric motor smaller, not as heavy, less expensive, and better at saving energy. As batteries get better, the motors will get better too. This will make the electric vehicles of the future even better than the ones we drive now. The motors are a very important part of this change.