Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Ever wondered how to obtain more power from your electrical motor? Or make it run cooler and conserve power? A big component of the solution hinges on something called motor lamination, and specifically, its lamination thickness. This article will guide you through why thinner laminations are frequently better. You’ll learn just how they can boost your motor’s performance and motor efficiency. It deserves reading because understanding this basic component can save you energy and money, and assist you build far better machines or motor-driven systems.

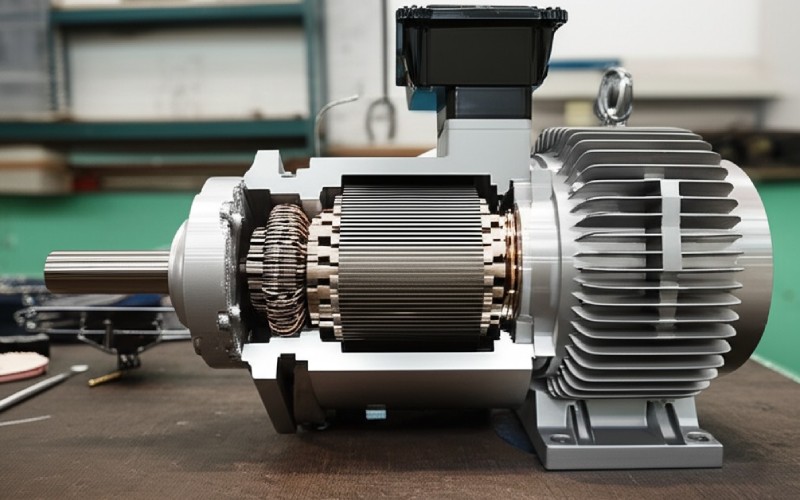

When we speak about a motor, particularly an electric one, we frequently think about wires and magnets. But there’s another super fundamental part: the lamination. Imagine really thin sheets of special material, like slices of bread. These sheet pieces are piled together to make up parts of the motor called the stator and rotor. These parts are the heart of the motor, where the magnetic fields do their job to make things spin.

Each sheet in this stack is a lamination. Why not make use of a solid block of steel, you ask? Well, solid steel would have huge troubles with something called eddy current loss. These currents are like little whirlpools of electrical energy that waste energy and make the motor warm. By using lots of thin lamination sheets, we break up the paths for these currents. This makes the motor work better. The material utilized for these lamination sheets is commonly a special kind of electrical steel. The lamination helps route the magnetic field in the motor. Consider it like roadways for the magnetic power to travel on. Good lamination planning makes sure this power goes where it needs to. This is critical for the motor to run well and provide great output. The stack of these lamination sheets develops the motor cores.

So, we understand lamination sheets are necessary. Yet why does the lamination thickness of each sheet matter so much for your motor? In my experience, this is an essential detail that can really alter a motor’s performance. The main factor is those annoying eddy current loss problems. The thinner the lamination, the more we can decrease these losses. This has a direct influence on just how well the motor runs.

Think of it in this manner: thicker sheets enable bigger whirlpools of current. Thinner sheets make these whirlpools much smaller. Smaller whirlpools mean much less wasted power and less warmth. This directly helps to boost the motor performance. A motor with reduced eddy current loss will run cooler and give you more power for the same quantity of electricity. This effect on efficiency can be quite big, particularly in a high-performance motor. So, when you select a lamination thickness, you are making a big choice about exactly how well your motor will certainly function. A thinner lamination frequently means better efficiency. We are constantly trying to make the motor much better, and the sheet thickness is one excellent way to do that. It can likewise influence the magnetic flux density within the motor.

The option of lamination thickness really does influence the whole plan for the motor. It’s not nearly picking a number. When a designer plans a new motor, the lamination thickness is a critical factor to consider. If we decide to utilize thinner laminations, it implies we’ll need much more individual sheets to make up the very same dimension stack for the stator and rotor parts of the motor.

This can alter the manufacturing procedure. Handling extra, extremely thin sheets can be more difficult. It could also add a little to the price of making the motor. Yet the benefits in performance and motor efficiency commonly make it worth it. The designer also thinks of exactly how the lamination thickness will certainly deal with the chosen material and the frequency at which the motor will run. For a high-speed motor, thinner laminations become much more crucial. Likewise, the lamination contributes to the overall weight and dimension of the motor. The density of the stack can transform a little bit with extremely thinner laminations because there may be a lot more insulation between layers. The plan needs to account for all these things to see to it the motor will certainly feature as planned. Every motor plan is an equilibrium of these aspects.

For high-performance electric motors, like those in an electric vehicle or a drone, every bit of motor effectiveness and power matters. This is where thinner laminations truly shine. These types of motor often perform at a higher frequency and need to provide a lot of torque swiftly. This kind of application is extremely demanding.

In such demanding uses, core loss ends up being a big opponent. Core loss includes two important things: hysteresis loss and eddy current loss. While the material selection assists with hysteresis, thinner laminations are superstars at reducing eddy current loss. When a motor rotates very quickly (high frequency), these eddy currents can be truly wild and produce a lot of warmth and waste. By using thinner laminations, we can keep these losses in check. This indicates the high-performance motor can run tougher, longer, and a lot more efficiently. So, if you’re collaborating with a high-performance motor, seriously check out making use of thinner laminations. It can make a significant difference in the general efficiency and the life of the motor. This is an usual technique for such electric motors. The innovation is constantly pushing for better performance.

Comprehending core loss is really the main point for why lamination options are so important for any kind of electrical motor. Core loss in a motor is the power wasted in the magnetic core, which is constructed from the lamination stack. This loss appears as heat. Way too much heat is bad for the motor and wastes power. This is a main concern for any type of motor device.

There are 2 main parts to core loss: hysteresis and eddy current losses. Hysteresis loss is related to the magnetic material itself. It’s the power needed to keep changing the direction of the tiny magnetic domains inside the material as the magnetic field in the motor changes. Choosing the ideal grade of electrical steel can aid minimize hysteresis loss. Imperfections in the material’s crystal structure or factors related to domain wall movement also contribute here.

Eddy current loss, on the other hand, is straight taken on by the lamination thickness. These are currents induced by the altering magnetic field inside the lamination sheets. Thicker sheets imply even more area for these currents to flow and trigger problems. By using a thinner lamination, we make it a lot harder for these currents to obtain strong. So, a great lamination strategy, making use of the appropriate product and optimum lamination thickness, is vital to decrease the overall core loss and make a much better motor. This results in lower core losses and much better heat dissipation.

For a very long time, 0.35 mm lamination thickness has actually been a common characteristic for several types of motor applications. And for good reason! It frequently provides a suitable equilibrium in between performance, expense, and simplicity of making. Numerous general-purpose electrical motors you see probably use lamination around this sheet thickness, possibly in the 0.35 mm to 0.5 mm variety. This quality of lamination is commonly readily available.

But should you constantly stick with 0.35 mm? Not always. If you’re aiming for higher motor effectiveness or making a motor that will operate at a higher frequency (like lots of modern electrical motors, specifically in hybrid cars or high-speed devices), going thinner than 0.35 mm can be a great alternative. We currently see lamination thicknesses like 0.2 mm, 0.15 mm, or even thinner being used. These can considerably reduce eddy current loss at higher frequencies, often measured in Hz.

The choice depends on your certain application and goals. If price is the absolute top concern and the motor runs at a low frequency (like 50 or 60 Hz), then 0.35 mm could be perfectly suitable. Yet if you need to eject even more performance or reduce heat, exploring thinner lamination choices is most definitely something I would certainly recommend. The distinction can be visible. The manufacturing approaches for these slim sheet components are likewise boosting.

Picking the appropriate lamination material is just as crucial as selecting the lamination thickness for your motor. The most typical material you’ll discover is electrical steel, likewise referred to as silicon steel. This isn’t just any type of steel; it has special magnetic properties that make it terrific for motor cores. The quantity of silicon in the steel aids increase its electric resistivity, which helps decrease eddy current loss. There are various grades of electric steel.

Some grades are better for reduced core loss, while others could offer greater magnetic flux density (implying they can take care of extra magnetic power). Some lamination products are designed for extremely high frequency applications. The grade you pick will rely on the motor’s requirements and, obviously, price. Much better grades generally cost much more. Always refer to the information sheets for the magnetic and mechanical residential or commercial properties of the material.

Past basic electrical steel, there are other sophisticated material alternatives for special motor kinds. As an example, amorphous metals or nanocrystalline materials can provide even reduced core loss, particularly at really high frequencies. However, these are frequently a lot more costly and can be more challenging to work with during production. For the majority of motor applications, a high quality electrical steel lamination is the way to go. The refining of these lamination products is a crucial part of manufacturing.

There’s no single magic number.. It’s about stabilizing several points. The key consideration is the motor’s operating frequency. As a rule of thumb, the higher the frequency, the thinner the lamination should be to maintain core loss down. You need to find the ideal equilibrium for your device.

Next, consider the efficiency requirements. If you require really high motor efficiency or if warmth is a big problem in your application (like in a tightly packed equipment or a lorry), then buying thinner laminations is typically a great concept. You also need to check out the magnetic flux density you expect in the motor. Some thinner lamination materials may saturate (get “full” of magnetism) a bit much easier, so the material selection and thickness require collaboration. This is a crucial step.

Lastly, cost is constantly an element. Thinner laminations can price more to purchase and potentially even more to assemble right into a stack. So, you need to consider the enhanced performance and motor effectiveness versus any kind of enhancement in expense. For lots of applications, computer system simulation software programs can aid groups model different lamination density alternatives and see their effect prior to building anything. This can assist you select the most optimal option for your motor.

While thinner laminations offer fantastic benefits for motor efficiency, they do come with some manufacturing challenges. Taking care of very slim sheet metal calls for more treatment. These sheets can be extra prone to bending or damages during refining like marking or laser cutting. This is a big consideration for the production line of any motor. The thickness of the iron in each lamination requires it to be just right.

Developing the motor lamination stack likewise obtains even more complicated. You have extra individual lamination items for the very same stack height. Aligning them flawlessly is important. The insulation coating on each lamination is likewise extremely thin, and it needs to be excellent to prevent short circuits in between layers. Any type of damage to this finish can harm the motor’s capability to combat eddy current loss. The method the motor is prepared needs to allow for these manufacturing tolerances.

These difficulties can occasionally raise the price of manufacturing motor cores with very thinner laminations, particularly for very thin gauges like 0.1 mm or 0.2 mm. Nevertheless, modern technology in manufacturing is constantly improving. We’re seeing much better ways to take care of and process these thin materials, making them a more sensible choice for a broader variety of motor kinds. The appropriate devices and strategies are vital.

So, we’ve travelled with the world of motor lamination thickness. As you can see, it’s a small detail with a large effect on your motor’s performance and motor efficiency. My major conclusion from years in this field is that you can’t neglect lamination thickness in your motor preparing. It’s an important variable that will affect just how the motor works.

While thinner laminations can decrease core loss, especially eddy current loss, and are great for high-frequency and high-performance electric motors, they aren’t always the default solution for every single motor. You need to think about your specific application, the operating frequency, your performance objectives, and the price. Sometimes, a common lamination thickness like 0.35 mm is perfectly fine. But also for numerous contemporary electrical motor applications, particularly in electric vehicles, hybrid systems, or any machine where performance is key, going thinner is usually the clever transfer to achieve better results.

The choice of lamination material, the grade of electric steel, and the lamination thickness all interact. The electromagnetic design of the motor depends heavily on this combination. I hope this guide helps you make better choices for your next motor project. Keep in mind to inspect data and customize your method to accomplish the optimum results for your motor or equipment. The goal is to get the most effective function and result from your machine.