Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Linear motions are so powerful, they show up everywhere. Linear motion is just a simple term for moving something in a straight line. You might not notice it, but this type of movement is the secret behind so many things we use every day, from a giant factory machine to the desk chair you might be sitting in.

This article will show you the most important application areas that use linear motion. Why should you read this? Because if you understand how linear motion works, you can see how to improve a process, invent a new product, or just appreciate the clever engineering all around you. We will look at what it is, where it’s used, and what makes a good system.

Let’s start with the basic idea. Linear motion is just movement along a straight path. Think of an elevator going up and down. That is linear motion. It moves in one direction at a time. This is different from rotation, like a spinning wheel.

Many types of equipment and machines require this kind of straight-line movement to do their jobs. Without linear motion, we couldn’t have 3D printers, assembly lines, or even an automatic door. It’s a key part of how we build and operate things in the modern world.

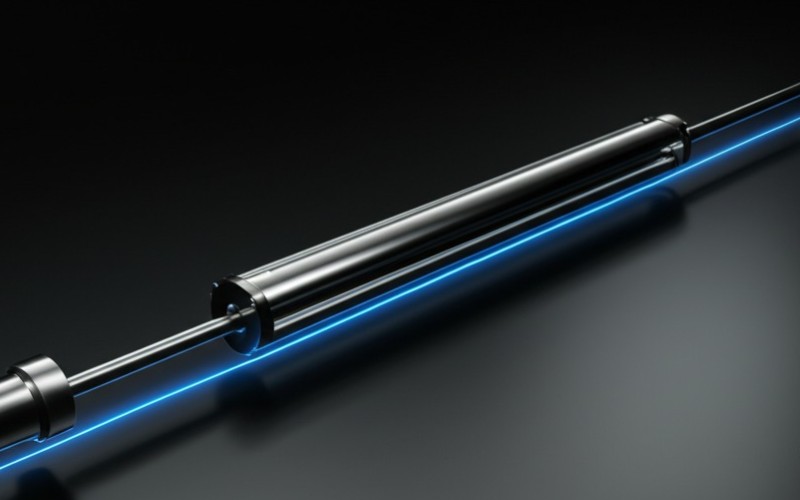

So, how do we make something move in a perfect line? A linear motion system usually has three main parts. You need a drive, a guide, and an actuator. Think of them as a team working together.

The drive is the engine. A common drive is a screw, like a lead screw or a ball screw. It turns rotation into linear motion. The guide, such as a set of linear rails, acts like a track. It makes sure the moving component does not wobble. The actuator is the part that does the work, pushing or pulling a load. This whole mechanism is designed to create precise, controlled movement.

The manufacturing industry is a huge user of linear motion. Almost every factory has some kind of application that uses a linear motion system. For example, a CNC machine uses a drive on each axis to move a cutting tool to a precise position. This allows it to carve parts out of metal or wood.

These systems are built to be strong and fast. They can carry a heavy load at high speed for hours. This is how we get mass production. A good linear motion system helps make more products in less amount of time. This helps a company make a better product and can reduce its operational costs.

One of the biggest benefits of linear motion is that it helps automate jobs. You can use linear actuators to build a system that does repetitive tasks. For example, an actuator can lift a box, push a part into place, or open a safety gate.

When you automate a task, you often improve safety for workers. You also get a better yield, which means more good parts and less waste. The key is the control you have over the movement. You can program a linear motion system to move to an exact position every single time. It’s a powerful way to make a production line more efficient.

The medical industry depends on precise and reliable linear motion. A great application is an adjustable hospital bed. A quiet electric actuator is used to lift the head or foot of the bed. This gives comfort to patients and helps nurses.

Another key piece of medical equipment is a CT or MRI scanner. These machines use a very smooth and steady linear motion system to move the patient bed through the scanner. The drive system for this application must be perfect. Any shaking could ruin the scan. This kind of system must also be very clean and durable. The duty cycle might be low, but the need for precision is very high.

You might be surprised how often you see a linear motion application at home. In adjustable standing desks, a linear actuator inside each leg lets you lift or lower the desk with the push of a button. An automatic door opener for a garage is another great example.

Even a reclining chair often uses a small actuator and screw mechanism. This linear motion device lets you lean back. It’s a simple operation, but it adds a lot of comfort. The drive is usually a small motor that is easy to integrate into the furniture’s design.

Choosing the right drive is a big decision. The main things to think about are the load (how heavy is the object?), the speed (how fast does it need to move?), and the precision requirement. A heavy load needs a strong drive mechanism.

Your main choices are often between screw drives and belt drives. A ball screw or a lead screw is great for precision and can handle a big load. Belt drives are a good option for high speed over a long distance. My first tip: always look at the specification sheet to see if the component meets your requirement. The final design must match the application.

The actuator is the muscle of a linear motion system. It is the component that takes energy, usually from electricity, and turns it into straight-line movement. Without an actuator, nothing would move. It is the core of any automated system.

There are many types. A simple mechanical actuator might use a crank. But today, electric linear actuators are very common. They are a single unit that contains a motor, a screw, and a rod that extends and retracts. You must choose an actuator that is strong enough for the load and fast enough for the job.

Control is the most important part of a modern linear motion application. If you can’t control the position and speed, the system is not very useful for a complex task. Good motion control makes sure a machine works correctly and safely.

You get this control from a controller and sensors. For high performance, you might use a servo motor, which gives great feedback. The controller is the brain that tells the drive where to go. This allows a robot arm to attach a tiny component in the right location. Good control also improves safety because the system knows where all its parts are at all times. Little to no play in the mechanism is often a key factor.

A great example is a multi-axis gantry system. It uses linear motion on an X axis and a Y axis to cover a wide area. This lets a machine work on a large part or in a big space. This kind of complex system has a high degree of complexity.

Another advanced application is in airplanes. A small, powerful actuator can move a part of a plane’s wing to help with steering. These parts must have extreme durability and be very reliable. This is where linear motion technologies show their full potential. They allow for new levels of functionality and performance. Here is a final tip: when you see any machine that moves something precisely, there is a good chance a linear motion system is at work.