Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

I’ve worked with electricity for many years. One thing I’ve learned is that heat is a big problem for a transformer. These amazing machines that power our world make a lot of heat when they work. If that heat is not taken care of in the right way, it can cause big trouble. This trouble can be anything from working poorly to breaking down completely. This is why it is so important to understand transformer cooling methods. In this article, I will show you all the different ways we keep these hard-working machines cool so they run well. We will look at easy ways like using air to cool things down. We will also look at harder ways that use oil and water. When you finish reading, you’ll understand why a good cooling system helps a transformer last a long time and work well.

Let’s begin with the simple facts. A transformer has the job of moving electricity from one place to another. This process is not perfect. Some power turns into heat. This heat is made in the transformer’s core and windings. If this heat is not removed, the transformer’s temperature will go up. This can cause a lot of damage. High temperatures can cause the special coatings inside the transformer to get ruined. This can cause short circuits or even a complete breakdown.

You can think of it like the engine in your car. It makes a lot of heat. If the cooling system stops working, the engine will get too hot and get damaged. The same thing is true for a transformer. A good cooling system is very important. It keeps the transformer working at a safe temperature. This makes sure it has a long life and works without problems. A cooling system has one main job. Its job is to move heat away from the transformer. It moves the heat into the air or water around it.

We can put transformers into two main groups: dry-type transformers and oil-immersed transformers. You might guess what this means from the names. The big difference is what they use to cool down. Dry-type transformers are cooled by air. Oil-immersed transformers use a special oil. Which type of transformer to use depends on a few things. These things are its power level, its job, and its location.

Dry-type transformers are used indoors a lot. You can find them in places like office buildings and hospitals. They are seen as safer because they do not have oil that can catch fire. Oil-immersed transformers are very common. You see them in outdoor power stations and for jobs that need a lot of power. This is because oil is a better coolant than air. Each type of transformer has its own set of cooling methods, which we will look at next.

Dry-type transformers use air for cooling. The simplest way is Natural Air (AN) cooling. With this method, the air around the transformer moves around its windings and core. This happens on its own and is called natural convection. As the transformer gets hot, the air around it gets warm, goes up, and is replaced by cooler air from below. This natural movement of air helps to get rid of the heat. This way is cheap and works well for smaller transformers that do not make a huge amount of heat.

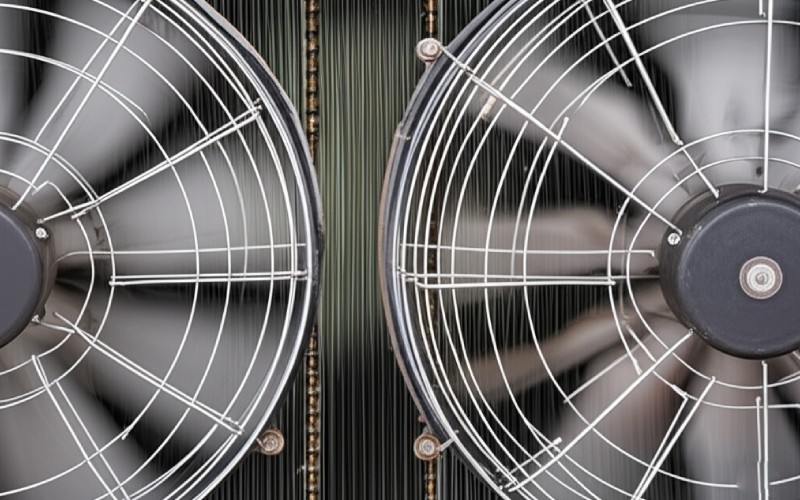

For bigger dry-type transformers, natural air cooling might not be enough. This is where Forced Air (AF) cooling is used. This method uses fans or blowers to push air over the transformer’s core and windings. This helps get rid of the heat much faster. This forced air circulation lets the transformer handle more power without getting too hot. Sometimes, a transformer uses both ways to cool down. This is called AN/AF. The fans only start working when the temperature gets to a certain level.

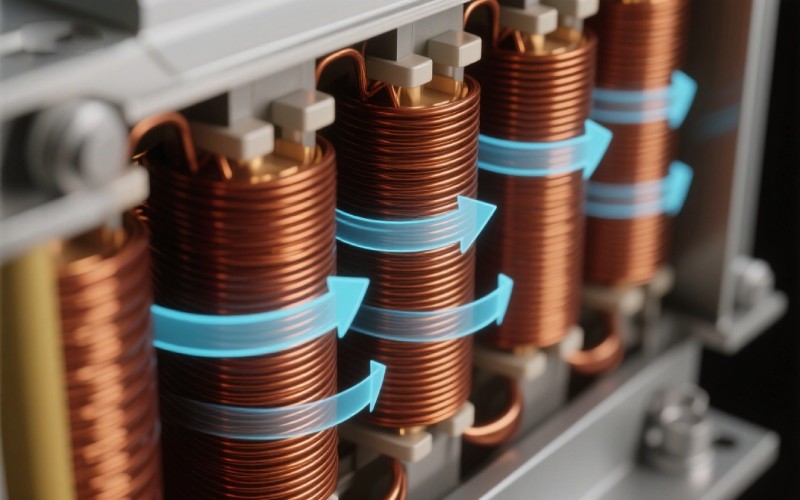

Now we will talk about oil-immersed transformers. The most simple cooling method for these is Oil Natural Air Natural (ONAN). In an ONAN transformer, the core and windings are put inside a tank that is full of transformer oil. This oil does two jobs. It stops electricity from going where it shouldn’t. It also helps cool the transformer. As the transformer works, the heat from the windings and core moves into the oil.

The hot oil is lighter, so it moves up to the top of the transformer tank. When it cools down, it gets heavier and sinks back to the bottom. This makes the oil move around on its own. We call this process natural convection. The heat then moves from the transformer tank to the air outside. To make the cooling better, the tank is often made with a bigger outside surface. This is done by adding cooling tubes or radiators. The ONAN method is simple, works well, and is used a lot for small to medium-sized transformers.

For bigger transformers that make more heat, the ONAN way of cooling might not be enough. In these situations, we need to help the cooling process a little bit. This is when we use the Oil Natural Air Forced (ONAF) method. The ONAF system is like the ONAN system, but with an added helper. The oil still moves around inside the transformer on its own because of convection. But, fans are added to the outside of the transformer, usually close to the radiators.

These fans blow air over the outside of the transformer tank and radiators. This helps the heat go away much faster. This forced movement of air helps to cool the oil better. This lets the transformer handle bigger jobs. The fans are usually controlled by a tool that checks the temperature. They only turn on when the oil gets too hot, which helps save power. The ONAF method is used often and is a good cooling choice for medium to large power transformers.

When we talk about very powerful transformers, even the ONAF method might not be strong enough to keep the temperature safe. For these bigger transformers, we need a stronger way to cool it. This is where the Oil Forced Air Forced (OFAF) method is used. In this system, we do not just wait for the oil to move on its own. Instead, a special pump is used to push the oil around through the transformer and its cooling system.

This forced movement of oil makes sure the heat moves away from the core and windings very fast and in a good way. On top of the forced oil movement, fans are used to blow air over the radiators. This is just like in the ONAF method. Using both forced oil and forced air gives us a very good cooling system. It can handle the large amount of heat made by very big transformers.

Yes, in some situations, water is used as a cooling liquid for transformers. This is often done in places where you can get water easily, like in power plants that use water to make electricity. The method is called Oil Forced Water Forced (OFWF). In this system, the hot transformer oil is pumped through a heat exchanger.

Inside the heat exchanger, heat moves from the hot oil to cool water. This water is moving through a different set of pipes. This is a very good way to cool things because water can soak up a lot more heat than air can. The OFWF cooling system is usually used for very large transformers. For these transformers, air cooling would not be good enough or work well enough.

Radiators and heat exchangers are very important parts of the cooling system for oil-immersed transformers. A radiator’s main job is to give more outside space for heat to move from the transformer oil to the air around it. Think about the radiator in your car. A transformer radiator works in the same way. The hot oil from the transformer moves through the radiator. The radiator is made of many fins or panels. This large outside area lets the heat go away faster.

A heat exchanger is a tool that moves heat from one liquid to another. The liquids do not touch each other. In an OFWF cooling system, the heat exchanger moves heat from the hot transformer oil to the cool water. Both radiators and heat exchangers have a big job. They make sure the transformer’s cooling system can get rid of the heat made while it is working.

To make all the cooling methods easy to understand, a system of cooling classes is used. These classes are shown with a four-letter code. This code tells you what is used for cooling and how it moves for both the inside and outside cooling systems. Here is a table that explains what the letters mean:

| Letter | Meaning |

|---|---|

| O | Mineral oil or special liquid with a fire point of 300°C or less |

| K | Special liquid with a fire point over 300°C |

| L | Special liquid with no known fire point |

| A | Air |

| W | Water |

| N | Natural movement (on its own) |

| F | Forced movement (using fans or pumps) |

| D | Directed forced movement |

For example, ONAN means Oil Natural Air Natural. ONAF means Oil Natural Air Forced. It is important to understand these cooling classes. This is true for anyone who helps plan, use, or fix transformers. It helps make sure the right cooling system is picked for the job.

Picking the right cooling method depends on a few things. These things are the transformer’s size and power, what it is used for, the air temperature around it, and how much it costs. Here is a simple guide:

Keeping a transformer cool is not just a good idea. It is very important for how well it works, how safe it is, and how long it lasts. There are many different cooling methods. They go from the simple natural air movement of a dry-type transformer to the strong forced oil and water systems of large power transformers. Each method was made for a different kind of job. By understanding these methods, we can make sure these important parts of our power system keep working well for many years.

Here are the key things to remember: