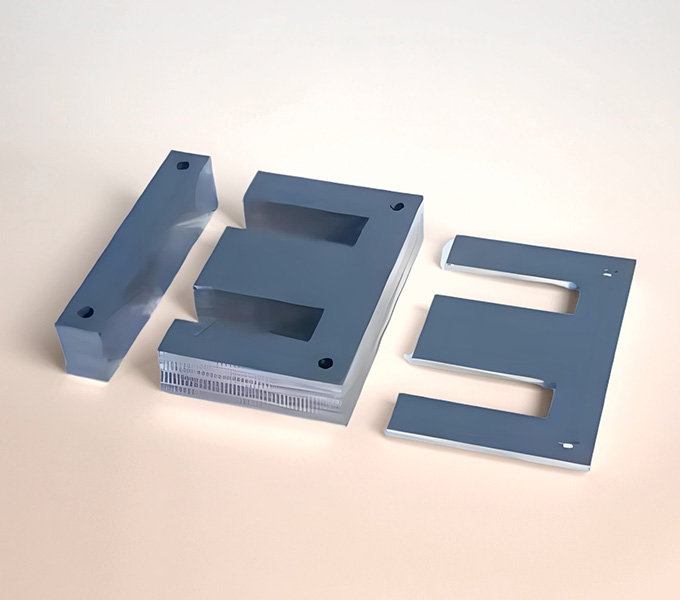

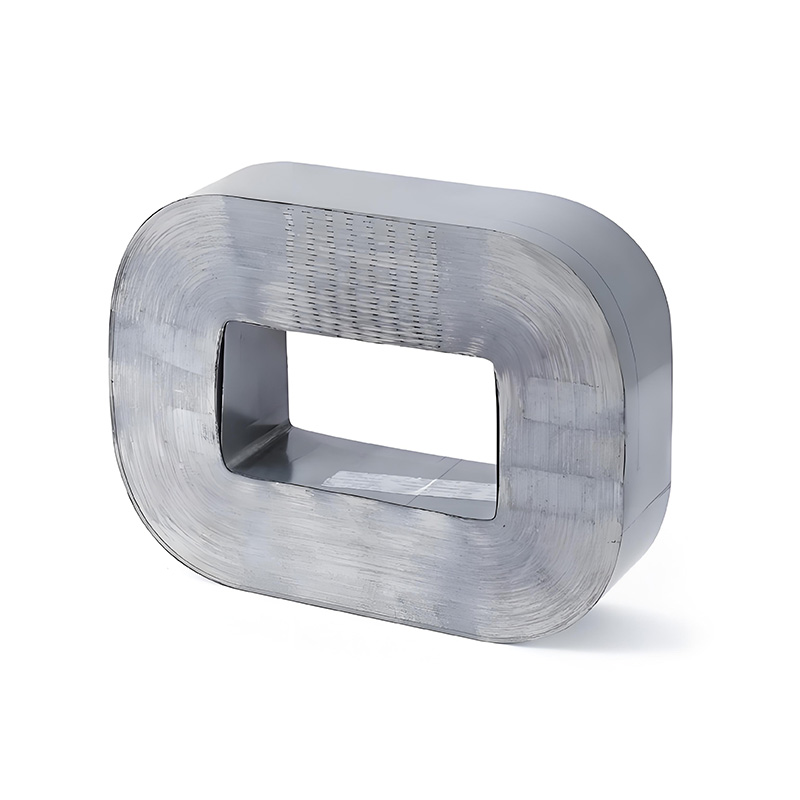

Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

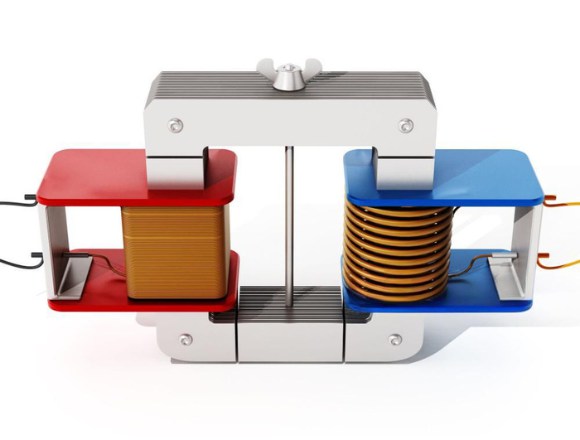

As Sino, a leading Chinese maker of transformer laminations, we are focused on helping our global partners by providing the best quality magnetic core parts. Our focus on new ideas, careful building, and deep knowledge of materials makes sure your transformers have unmatched efficiency, are very reliable, and work great in many different uses.

The material choice is absolutely paramount for achieving optimal performance, and at Sino, we’re uncompromising on quality. We don’t just grab any sheet metal off the shelf. Our transformer laminations are predominantly crafted from high-grade silicon steel. Why silicon steel? It’s the industry standard for very good reasons:

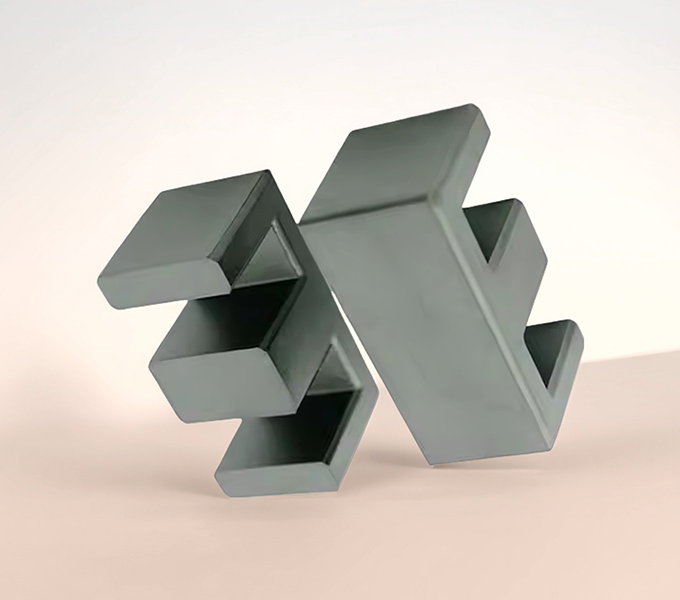

The best choice and design of transformer laminations really depend on the specific use. At Sino, we know that a single solution doesn’t work for everything. We customize our lamination parts to fit the special needs for performance, cost, size, and the environment of different kinds of transformers and industries.

For large power and distribution transformers, efficiency and long-lasting reliability are most important.

Uses like switch-mode power supplies (SMPS), resonant converters, and EV onboard chargers run at very high frequencies, so they need special lamination parts.

For high-quality sound systems, the main goal is linearity, low distortion, and a wide range of sound frequencies.

For motors, generators, and other industrial gear, magnetic properties that are the same in all directions are often more important than properties that are strong in just one direction.

Strength: Laminations for rotating machines must handle major mechanical forces and shaking.

These fields need things to be extremely reliable, very light, and powerful for their size, often in tough conditions.

Because we deeply understand these different needs, we can work with you to give you not just laminations, but solutions made just for you. This will improve your transformer designs for what they are meant to do, making sure they work their best and give you an edge over competitors.

Sino offers and expertly processes a range of lamination materials, ensuring you get the optimal fit for your specific needs:

Feature | Amorphous Metals (When Sourced for Special Projects) | ||

Sino’s Argument For Use | For scenarios demanding the absolute lowest core loss and highest efficiency, where flux travels in a predictable direction. Sino ensures optimal grain alignment during processing. | For cost-effective solutions where magnetic properties need to be consistent in multiple directions within the sheet. Sino provides high-quality NGOES for diverse machinery. | For cutting-edge, high-frequency applications where minimizing losses is critical and justifies a premium material. Sino has the capability to process these delicate materials precisely. |

Typical Sino Client Scenarios | Large power transformers for utility grids, high-efficiency distribution transformers. A recent project involved supplying CRGO laminations for a regional substation upgrade, resulting in a documented 2% improvement in overall grid efficiency. | Electric motors, generators, smaller industrial transformers, lighting ballasts, and appliance transformers. We regularly supply NGOES laminations to motor manufacturers, helping them achieve better energy ratings. | Switched-Mode Power Supplies (SMPS), specialized medical equipment transformers, renewable energy inverters. We partnered with a medical device company to develop a compact, ultra-efficient power unit using amorphous cores. |

Key Characteristics | Anisotropic – magnetic properties are optimized along the grain (rolling) direction. This requires precise cutting and stacking, a Sino specialty. | More uniform (isotropic) magnetic properties. Offers good performance with more design flexibility. | Non-crystalline (glassy) structure, typically supplied as very thin ribbons (e.g., 0.025 mm). Requires specialized handling and stacking, which Sino has mastered. |

Considerations/Trade-offs | Higher material cost than NGOES; performance is sensitive to mechanical stress and ensuring flux aligns with the grain. Sino’s careful handling minimizes these sensitivities. | Higher core losses compared to CRGO. However, its versatility and cost-effectiveness make it ideal for many scenarios. | More brittle, generally higher cost than silicon steels, and can have a lower saturation flux density. Best for specific high-frequency, low-loss demands. |

Sino also gives information on these comparisons, looking at how well they work, how hard they are to make, and how much they cost.

Feature | Laminated Silicon Steel (GOES/NGOES) | Amorphous Metal | Nanocrystalline | Ferrite |

Saturation Flux Density (Bs) | High (up to 2.0 T) | Medium (1.56 T) | Medium (1.2-1.5 T) | Low (0.3-0.5 T) |

Core Losses (50/60 Hz) | Medium | Very Low | Very Low | High |

Core Losses (High Freq) | High (unless ultra-thin) | Low | Very Low | Very Low |

Electrical Resistivity | Medium | High | High | Very High |

Strength | Good | Brittle | Very Brittle | Very Brittle |

Material Cost | Low to Medium | High | Very High | Medium |

How Hard to Make | Low to Medium | High | Very High | Medium |

Common Uses | Power, Distribution, Motors | Distribution | High-Freq Power | Very High-Freq |

Our material choices and processing techniques are always guided by industry best practices and standards, such as those defined by IEC (International Electrotechnical Commission) and ASTM International. We source our raw materials from reputable mills known for their consistent quality, ensuring that the foundation of your transformer laminated core is solid.

At Sino, we don’t just see ourselves as suppliers of transformer laminations. We aim to be your trusted partner in achieving optimal transformer performance. We know that sometimes an off-the-shelf solution isn’t quite right.

1

Do you have a unique footprint, a specific loss target, or a challenging operating environment? Talk to us! Our engineering team thrives on such challenges. We can work with you to design and manufacture custom transformer laminated core solutions tailored precisely to your requirements.

2

Got questions about material selection? Unsure about the best lamination thickness for your frequency? Our experienced team is here to provide guidance and support, helping you navigate the technical complexities and make informed decisions.

3

We take the time to understand your broader project goals. By knowing what you’re trying to achieve, we can often suggest subtle improvements or alternative approaches for your transformer laminations that you might not have considered, potentially saving you cost, improving performance, or accelerating your time to market.

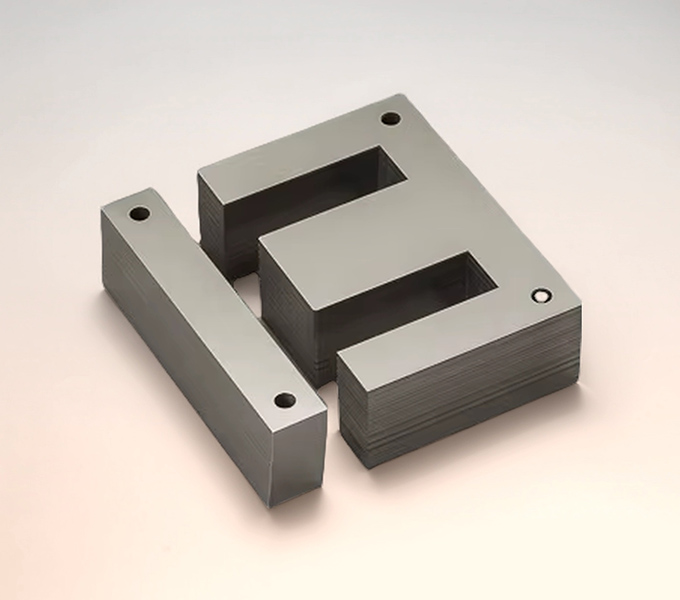

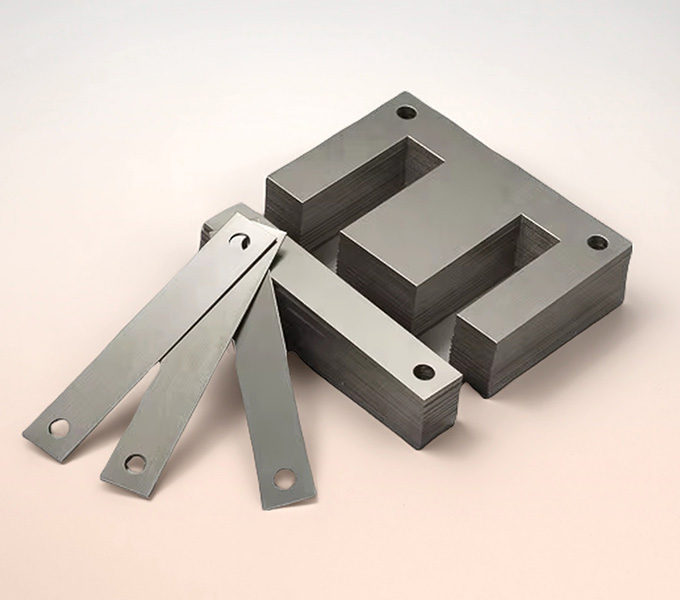

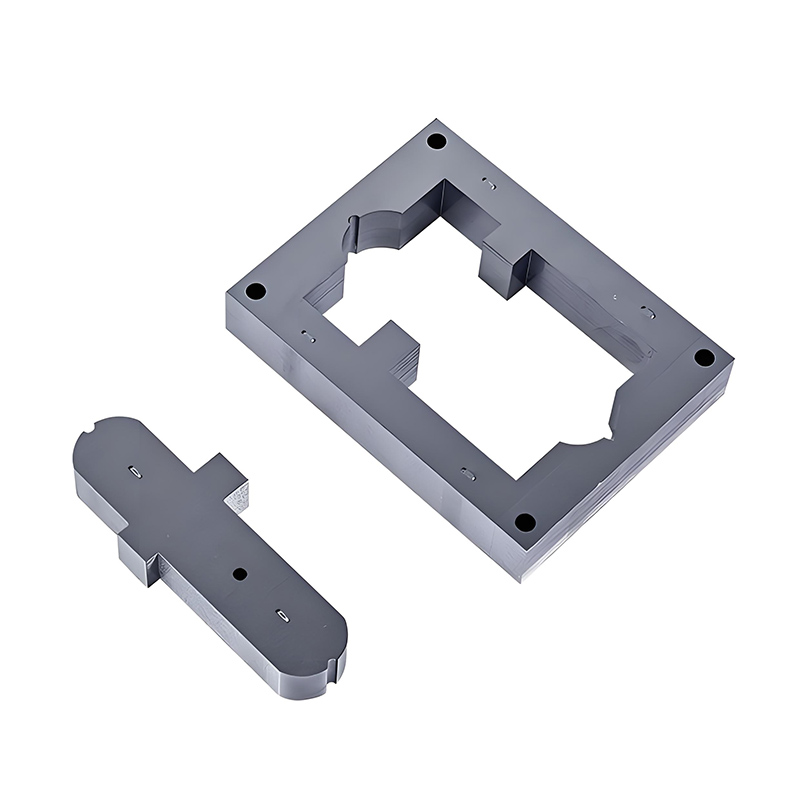

Having the best materials is only half the battle. How those materials are transformed into the final transformer laminations and assembled into a core is where Sino’s manufacturing prowess truly shines. The little details make a world of difference:

At Sino, we employ precision tooling, regular maintenance, and, where necessary, de-burring processes to ensure our laminations are smooth and clean. This was critical for a client manufacturing sensitive audio transformers, where even minute core imperfections could introduce audible hum. Our burr-free laminations helped them achieve pristine sound quality.

To counteract mechanical stresses which are introduced by the processes of stamping, cutting, and handling, many of our transformer laminations undergo a critical heat treatment process called annealing. By carefully heating and cooling the laminations in a controlled atmosphere, we relieve these internal stresses, restoring the material’s optimal magnetic performance and ensuring your laminated core of transformer performs exactly as designed.

When you choose Sino for your transformer laminations, you’re choosing more than just a component. You’re investing in:

Our precision-engineered laminations are designed to slash energy losses, reducing operational costs and contributing to a greener footprint.

Quality materials and meticulous manufacturing mean cores that stand the test of time, ensuring the longevity and dependability of your transformers.

Whether it's minimizing noise, maximizing power density, or hitting stringent efficiency targets, Sino laminations help your transformers perform at their peak.

We're here to support you from concept to completion, offering expertise, customization, and a commitment to your success.

The world runs on electricity, and transformers are the unsung enablers of that power. At Sino, we’re proud to craft the critical transformer laminated core components that make it all possible, efficiently and reliably.

Ready to see how Sino’s transformer laminations can elevate your next project? Reach out to our team today! Let’s discuss your specific needs and discover how we can help you build better, more efficient, and more reliable transformers. We’re excited to put our expertise to work for you.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.