Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

A DC motor is a machine that changes electricity into movement. It is a very simple and common kind of motor. But how do you change how fast it spins? This is what we call DC motor speed control. Knowing how to manage the motor’s speed is very important for any project. This is true for small things like robots and big things like factory machines. This article will show you easy ways to control the speed. You will learn about the different ways to do it. We will cover everything from simple voltage control to more advanced ways that use quick pulses of electricity. This guide will make it easy for anyone to learn how DC motor speed control works.

A DC motor is a device that turns electric power into moving power. It uses a type of electricity called direct current (DC). This is the kind of power that you get from batteries. The main idea of how DC motors work is quite simple. Inside a DC motor, you will find a coil of wire and a magnet. When electricity goes through the coil, it makes a magnetic field. This new magnetic field pushes against the magnet’s field. This push is what causes the middle part of the DC motor to spin.

In a brushed DC motor, there is a part called a commutator. This part helps the motor to keep on spinning. The commutator is a special switch. It flips the direction of the electricity going to the coil with every half turn. This action keeps the magnetic forces pushing in the right way. As a result, the DC motor continues to turn. The speed of the DC motor depends on the voltage you give it. More voltage will make it go faster. This simple rule is the starting point for all DC motor speed control. This is not like an AC motor, which uses a completely different kind of power. A DC motor is a great choice for a lot of different projects.

Being able to control the speed of a DC motor is a very big deal. Just think of a toy car. You want the car to be able to go fast, but you also want it to go slow. If there was no motor speed control, it would have only one speed: as fast as possible. Speed regulation is what lets you make the DC motor do exactly what you need it to do. You need this kind of exact control for things like robots, fans, pumps, and many other devices. For instance, a robot arm sometimes needs to move slowly and with great care. At other times, it needs to move very quickly.

Good motor control also helps you save on power. If you run a DC motor at its top speed all the time, it uses a large amount of energy. When you adjust the speed to fit the job, you use less power. This is especially important for any gadget that runs on batteries. Using the right controller and control method can make your project work better without wasting power. Making proper speed adjustments can also make the DC motor and its parts not wear out as fast. This helps them last for a longer time. Learning about DC motor speed control is a very useful skill to have.

The most simple way to control the speed of a DC motor is to change the resistance in the electrical path. You can do this by putting a resistor in the way of the electricity that is going to the DC motor. We call this method resistance control. An easy way to do this is by using a variable resistor. When you change the setting on the resistor, you change how much voltage can get to the DC motor.

This way of controlling the speed is very simple, but it has some big problems. The resistor gets very hot. This is because it turns a lot of the electrical power into heat. This heat is just wasted power. Also, when the job the DC motor is doing gets harder or easier, its speed will also change. If the DC motor needs to work harder, the load torque goes up, and the motor will start to slow down. This method is okay for a very basic speed job. However, for most projects, you will want a better way to control your DC motor.

The speed of a DC motor is directly linked to the amount of voltage it gets. This means that if you turn up the supply voltage, the motor speed will also go up. If you turn down the voltage, the motor speed will go down. This is the most simple and important rule of DC motor speed control. This method has a name: voltage control or drive voltage control. You can control a DC motor by hooking it up to a power supply that lets you change the voltage it puts out.

Let’s picture a simple circuit for a DC motor. When the voltage is turned up high, a lot of current goes through the coil. This creates a powerful magnetic field, which makes the DC motor spin very fast. When you lower the voltage, not as much current can flow. This makes the magnetic field weaker, and so the DC motor spins more slowly. You can count on this link between voltage and motor speed. The hard part is finding a good way to change the voltage that doesn’t waste power. Just using a resistor wastes a lot of energy. For this reason, smart people have made better circuits to control the voltage for any DC motor.

Pulse Width Modulation, which is often called PWM, is a much better way to control the speed of a DC motor. Instead of just lowering the voltage level, a PWM controller turns the power to the DC motor on and off at a very fast pace. It sends a bunch of quick bursts of electricity. The “pulse width” tells us how long each burst of power lasts. We call this on-off pattern the duty cycle. If the “on” time is long, the DC motor gets more power and it will spin faster. If the “on” time is short, it gets less power and it will spin slower.

This method works very well and does not waste much power. The switch in the drive circuit is either all the way on or all the way off. Because of this, very little power is lost as heat. The PWM signal makes the DC motor act like it is getting a steady, lower voltage. For instance, if the power is on for half of the time (which is a 50% duty cycle), the DC motor will behave as if it is getting half of the full voltage. PWM gives you very exact control over the motor speed. Many new systems for controlling motors use PWM to manage a DC motor. This is a very common choice among all the control techniques.

| Control Method | Good Points | Bad Points |

|---|---|---|

| Resistance Control | Very simple circuit, costs little money. | Wastes a lot of power as heat, does not hold speed well. |

| Voltage Control | Easy to understand and use. | Can waste power if using a certain type of regulator. |

| PWM Control | Wastes very little power, gives exact control. | The circuit is more complicated, can create electrical noise. |

Yes, there are a few main kinds of DC motors. The ones you will see most often are brushed DC motors and brushless DC motors. A brushed DC motor is a simple and low-cost choice. It uses small carbon blocks, which are called brushes, and a commutator to send power to the part that spins. These motors are not hard to control. They also have a high starting torque. This means they are very strong right when they start up. This quality makes them a great choice for many easy jobs.

There are also other kinds of brushed DC motors, such as series, shunt, and compound motors. A shunt DC motor is one kind where its wires are connected in a special way called ‘in parallel’. Another kind is the permanent magnet DC motor. This one uses a permanent magnet to make its magnetic field. Each of the types of DC motors has its own way of handling speed and turning force. Choosing the right DC motor is based on what your project needs to do. The main ideas of speed control of dc motors, like changing the voltage, will work for most of them.

Brushless DC motors, which are also known as BLDC motors, are a newer and better kind of electric motor. They are different from brushed DC motors because they do not have any brushes or a commutator. Instead of those parts, they use an electronic speed controller (or ESC) to change which way the electricity flows in the coils. A special drive circuit does this job. A sensor, which is often a Hall effect sensor, tells the controller where the spinning part is. This way, the controller knows which coil to send power to next.

The main good points of brushless DC motors are that they work well without waste and last for a long time. Since there are no brushes to get worn out, you don’t have to fix them very often. They also make less noise and can spin at higher speeds. The speed of a brushless DC motor is managed by the electronic controller. This controller often uses PWM. The controller can change the timing and the duty cycle of the power bursts that go to the motor’s coils. Even though brushless DC motors and their controllers are a bit harder to use, they are the top choice for jobs that need the very best performance, like drones, electric cars, and fans inside computers.

An H-Bridge is a special type of electronic circuit. It lets you control a DC motor to go forwards and backwards. It is also used to control the speed of the motor. The circuit got this name because a picture of how its switches are laid out looks like the letter “H”. The DC motor is connected in the middle part of the “H”. The circuit has four different switches, which are usually transistors. By turning on two switches at the same time, you can change the direction the electricity flows through the DC motor.

An H-bridge circuit also works great for using PWM to control the speed. You can send a PWM signal to the switches. This will let you control the motor speed in either direction. This gives you complete control over both the speed and the direction of a DC motor. Many motor controller chips and DC drives already have an H-bridge circuit built inside them. The H-bridge circuit is a very important part in making robots work, and it is used in many other control systems too. You can also use an H-bridge circuit with brushless DC motors, but the drive circuit for them is more complicated.

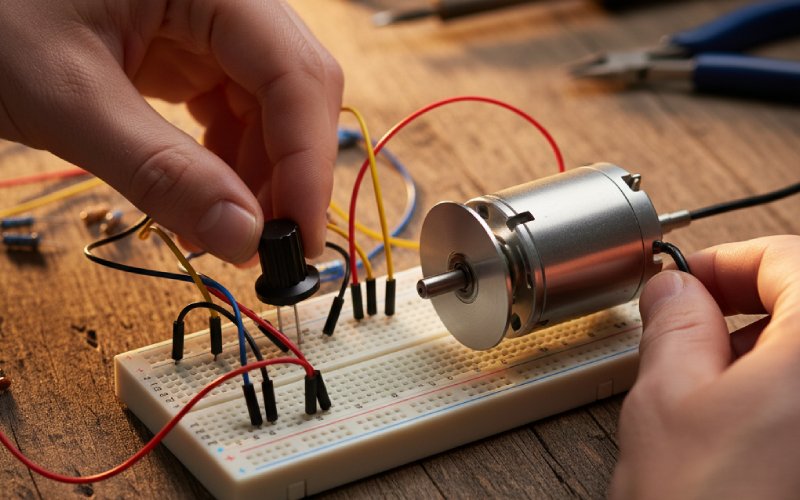

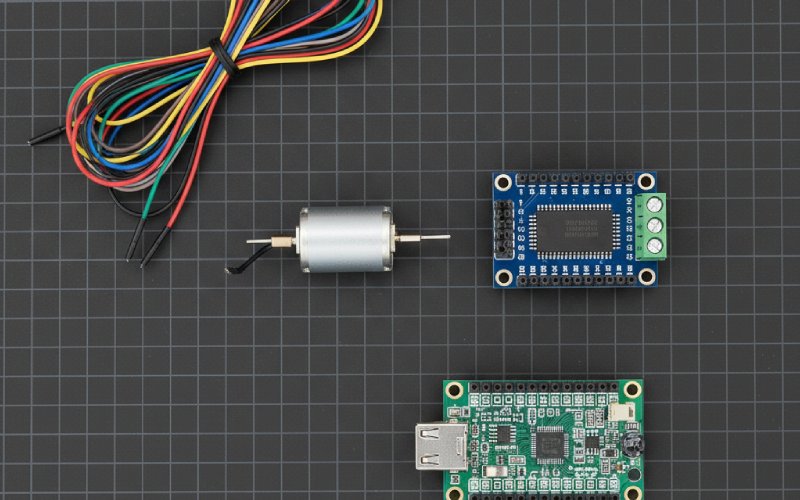

The type of controller you will need is based on your DC motor and on what you want the motor to do. For a very simple project, you might only need a switch and a variable resistor. But to make it work better, you will need an electronic speed controller. A controller made just for motors can use PWM for controlling the speed without wasting power. Some controllers are simple analog circuits. Others use a tiny computer, like a microcomputer or a microcontroller such as an Arduino, to make the PWM signals. Using a microcomputer gives you more advanced ways to control the motor.

For brushless DC motors, you have to use a special electronic speed controller (ESC). This kind of controller can do the complicated switching work that is needed to make the motor turn. Servo motors are another kind of DC motor. They have their own controller circuit built right inside them. This allows for very exact control over its position. When you are picking out a controller, you need to be sure it can work with the amount of voltage and current that your DC motor requires. A good controller will give you very exact control over your DC motor’s speed and torque. The controller is like the brain for your motor.

Understanding how speed, voltage, and torque work together is very important for knowing how a DC motor works. As we have already talked about, the speed of a DC motor is mostly connected to the voltage. But torque is mostly connected to the current. Torque is the turning power of the motor—you can think of it as its “strength.” When the DC motor is doing a hard job (meaning the load torque is high), it needs more current. This extra current helps it create more torque to handle that job.

When you give a certain amount of voltage to your DC motor, it will want to spin at one speed (this is its no-load speed). When you make the motor do work, it slows down just a little bit. It also pulls in more electricity to make the torque it needs to do the work. If the job is too hard, the motor might stop spinning. If this happens, it can pull in a very large amount of current, which could break it. A good speed control system, especially one that uses a speed sensor to check its speed, can change the voltage or the PWM duty cycle. This helps to keep the speed the same, even when the amount of torque changes. Knowing how speed and torque affect one another is very important for any project that uses a DC motor.