Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

This article is for you if you’ve ever heard a strange noise from your washer, wondered why new machines are so quiet, or are a curious DIY-er. I’m going to break down the difference between a rotor and a stator, explain why they don’t have their own bearings, and give you the knowledge to understand, troubleshoot, and maybe even repair your own machine. It’s simpler than you think, and understanding it can save you a lot of money and headaches.

Let’s start at the beginning. For decades, most washing machines used a traditional motor. This motor sat at the bottom of the machine and was connected to the drum by a belt and pulley, kind of like the fan belt in your car. It worked, but it had a lot of moving parts. More parts mean more noise, more vibration, and more things that can break.

Then, companies like LG and Samsung introduced the direct drive motor. The idea was pure genius in its simplicity. Instead of having a separate motor connected by a belt, they integrated the motor directly with the drum. The motor’s shaft is the same drive shaft that spins the tub. This got rid of the belt, the pulley, and a lot of the noise. This new design is often called a brushless DC motor (or BLDC motor) because it doesn’t have the old-style carbon “brushes” that would wear out over time.

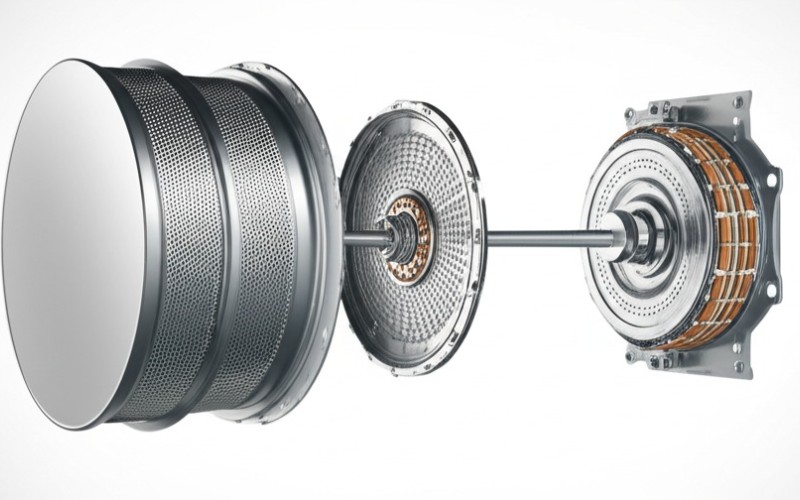

When you look at a direct drive motor, you aren’t looking at one single part. You are looking at an assembly made of two main pieces: the rotor and the stator. These two parts work together to create rotation without ever touching each other. This design is the reason modern washers are so much quieter and often come with a 10-year warranty on the motor. They have fewer moving parts, which means greater durability and efficiency.

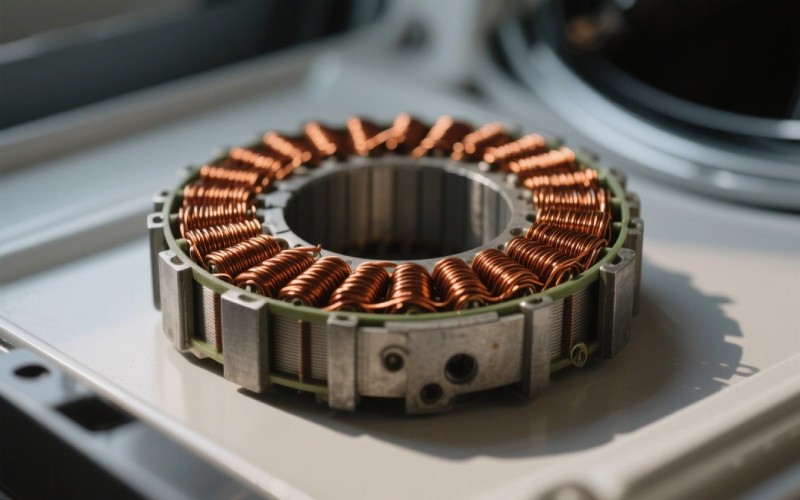

If you take the back panel off your direct drive washer, the first thing you’ll likely see is the rotor. But if you unbolt and remove the rotor, you will find the stator. The word “stator” comes from the word “stationary,” and that’s the key to remembering what it is. The stator does not move. It is bolted directly to the back of the washing machine tub. It’s a heavy, round metal ring packed with dozens of tightly wound copper windings.

These copper windings are organized into groups called coils. When you turn on your washing machine, the machine’s computer sends alternating current (AC) power to these coils. This electricity running through the coils creates a powerful, changing electromagnetic field. The computer can control which coils get power and when. This allows it to precisely control the speed and direction of the motor.

The stator is an incredibly reliable part. Because it doesn’t move, there is very little wear and tear on it. The main point of failure for a stator is usually electrical. A power surge could damage the windings, or over time, the insulation on the copper wire could break down, causing a short. But physically, it’s a solid, durable component. It’s the fixed, electronic heart of the motor assembly.

Now for the other half of the team: the rotor. As you might guess from its name, the rotor is the part that “rotates.” It’s a large, bowl-shaped piece of metal that fits over the stator. When you first held one, you may be surprised by its weight. The reason it’s so heavy is that the inside rim is lined with a series of very strong, permanent magnets. These aren’t your refrigerator magnets; they are powerful rare-earth magnets.

The rotor is connected directly to the washing machine drum. In the center of the rotor, there is a hub with teeth or grooves called splines. These splines lock onto the end of the drum’s drive shaft. So, when the rotor turns, the shaft turns, and the drum turns. It’s a direct, one-to-one connection. This direct link is what gives the motor incredible torque, which is the twisting force needed to tumble heavy, wet clothes.

Unlike the stator, the rotor is a purely mechanical part. It has no wires and receives no direct electrical power. Its only job is to hold the magnets and connect to the shaft. The most common failure with rotors is physical damage. Sometimes one of the magnets can crack or come loose. This is rare, but it creates a very distinct clicking or knocking noise as the loose magnet hits the stator.

This is a great question and a point of confusion for many people. The statement that a direct drive motor has “no bearings” is both true and false, depending on how you look at it. A traditional, self-contained motor has its own casing, and inside that casing are bearings that allow its shaft to spin smoothly. The direct drive motor does not have this. The rotor and stator are just two separate components. They do not have their own dedicated bearings within a motor housing.

However, the whole system absolutely needs bearings to work! The main drive shaft that the rotor connects to, and that the stator surrounds, runs through the center of the stationary outer tub. This shaft is supported by two large, heavy-duty bearings that are pressed into the back of the tub assembly. These are the main tub bearings. So, the rotor “borrows” the tub bearings to spin.

This is a clever design. It reduces the total number of parts in the machine. But it also means that a bearing failure is a much bigger job. On an old machine, if a motor bearing went bad, you replaced the motor. On a direct drive machine, if a tub bearing goes bad, it creates a loud roaring noise during the spin cycle. To fix it, a technician has to perform a major repair, taking the entire machine apart to replace the bearings in the tub. The rotor and stator themselves are fine, but the system they rely on has failed.

The way these two parts create rotation is a beautiful example of physics at work. It’s like a perfectly choreographed dance of magnetic forces. As I mentioned, the stator uses electricity to create a changing electromagnetic field. Imagine this field is like a series of invisible hands, appearing and disappearing in a circle around the stator.

Now, remember the rotor has its own permanent magnets. These magnets are naturally attracted to and repelled by the electromagnetic field from the stator. The washing machine’s computer cleverly turns the stator’s coils on and off in a precise sequence. This creates a rotating magnetic field. This field essentially “pulls” the rotor’s magnets along with it, forcing the rotor to spin.

Think of it like this: Imagine you are holding a magnet, and I have another magnet on a string. If I move my magnet in a circle, your magnet will try to follow it. The stator is my moving magnet, and the rotor is your magnet on the string. This magnetic force is what generates the smooth, powerful torque to spin the drum. Because nothing is physically touching (except for the main shaft in its bearings), the quiet operation is remarkable.

You will often hear the terms direct drive motor, inverter motor, and brushless DC motor (BLDC) used when talking about modern washers. This can be confusing. For the most part, when it comes to washing machines, they are all referring to the same core technology.

Let me break it down simply. “Brushless DC motor” is the technical name for the motor type. It describes a motor that uses permanent magnets on the rotor and electronically controlled coils on the stator, without the need for physical brushes. “Direct Drive” describes how the motor is connected to the drum—directly, without a belt.

“Inverter” describes the technology that controls the motor. An inverter is a sophisticated circuit board that takes the standard AC power from your wall outlet and converts it into the variable frequency DC power that the brushless motor needs. This inverter is what gives the computer precise control over the motor’s speed and torque. So, a direct drive washer uses an inverter motor, which is a type of brushless DC motor. The terms all point to the same efficient, quiet, and durable system.

The first and most obvious benefit is the quiet operation. Without a belt whining and a traditional motor humming, the only sounds you really hear are the water and the clothes tumbling. This is a huge plus if your laundry room is near your living space.

The second major benefit is efficiency. These motors use less electricity because there is no energy lost to friction from a belt and pulley system. The inverter technology also allows the motor to use exactly the amount of power needed for the load, no more, no less. This saves you money on your utility bills over the life of the machine.

Finally, there’s durability. The simple rule in mechanics is that fewer moving parts means fewer things can break. Getting rid of the belt and pulley eliminated the most common mechanical failure point in older washers. This is why manufacturers like LG and Samsung are confident enough to offer long warranties on their direct drive motor parts. The design has proven itself to be incredibly reliable.

Even the best designs can have problems. The most frequent problem isn’t with the motor itself, but with a small part inside it: the hall sensor, or position sensor. This sensor tells the computer the exact position of the rotor. If it fails, the motor might jerk back and forth or not spin at all. This is a relatively easy and inexpensive repair.

A more serious, though much rarer, failure is a problem with the stator’s copper windings. A power surge or a manufacturing defect could cause a short in one of the coils. A diagnosis for this involves testing the electrical resistance between the pins on the stator’s wiring harness. If the readings are wrong, the stator needs a replacement.

For the rotor, the main issue is a cracked or loose magnet. This usually happens because of a severe out-of-balance load causing extreme vibration, or sometimes from a foreign object getting between the rotor and stator. You will hear a loud clicking or grinding noise. A visual inspection is usually all the diagnosis you need. In most cases, you have to replace the entire rotor assembly.

Troubleshooting these motors is fairly straightforward if you know what to look and listen for. Your first clue will often be an error code on the machine’s display. An “LE” error code on an LG machine, for example, often points to a locked motor error, which could be the hall sensor, the stator, or a wiring issue.

Listen carefully to the noise the machine is making. A loud, roaring or grinding sound that gets worse as the machine spins faster is almost always the main tub bearings, not the motor itself. A rhythmic clicking or ticking sound that matches the drum’s rotation could be a loose magnet on the rotor. A motor that hums but doesn’t turn, or that twitches back and forth, often points to a bad hall sensor or a problem with the stator or its wiring.

A visual inspection can also tell you a lot. Unplug the machine and remove the back panel. Look at the stator’s coils. Do you see any black, burnt-looking spots? That’s a sure sign of a failed stator. Gently try to wiggle the rotor. Is there any play? Can you see any cracked or missing magnets? This simple troubleshooting can help you or a technician pinpoint the problem quickly.

This is the million-dollar question. Can you handle the replacement yourself? My answer is: it depends on the job and your comfort level. Replacing the rotor or the hall sensor is a job that many handy homeowners can do. It usually involves removing one large bolt in the center, sliding the old rotor off, and sliding the new one on. The hall sensor is similarly easy to access once the rotor is off.

Replacing the stator is a bit more involved. You have to disconnect the wiring harness and unbolt the stator from the tub. It’s heavier and more awkward, but still very doable for a careful DIY-er.

The one job I do not recommend for most people is replacing the main tub bearings. This is a major repair that requires a near-total disassembly of the washing machine. You need special tools to press the old bearings out and the new ones in. While it’s possible, it’s a long and difficult job. For a bearing failure, my advice is usually to call a qualified technician. Knowing the difference between a simple rotor replacement and a complex bearing job is key to a successful repair.

A: The motor itself, meaning the rotor and stator, often lasts for the lifetime of the appliance. That’s why they have 10-year or even longer warranties. The parts that support it, like the hall sensor or the tub bearings, are more likely to fail first.

A: They used to be, but the technology is now very common, especially in mid-range and high-end machines. The price difference is much smaller now, and the long-term savings in efficiency and durability often make them a better value.

A: Generally, no. The magnets are glued in with very strong epoxy. It is much easier and safer to perform a replacement of the entire rotor assembly. They are sold as a single part.

A: Not at all. A failure to spin can be caused by a bad lid switch, a clogged drain pump (the machine won’t spin if it can’t drain), a broken hall sensor, or a problem with the main control board. A proper diagnosis is needed to avoid replacing parts you don’t need to.