Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

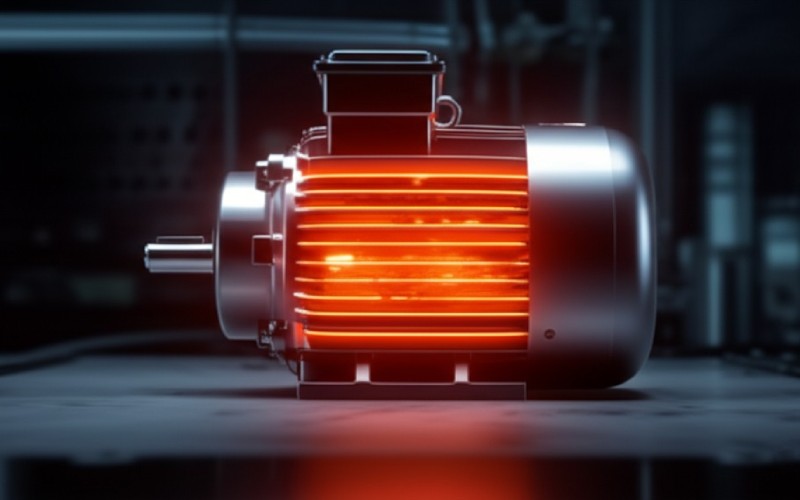

Motor overload is a genuine migraine when an electrical motor instantly quits. This post is below to aid you recognize what motor overload really suggests for your motor. We’ll check out the usual causes, consisting of electric overload concerns. Recognizing this can save you time, cash, and a great deal of frustration. If you like maintaining your motor in leading form and preventing pricey motor failure, then this article is absolutely worth your time.

When we speak about motor overload, it’s rather basic at its core. It indicates your motor is being asked to do more work than it was built for. Picture you’re trying to raise a box that’s way too hefty. You would certainly strain, and you might not have the ability to lift it, or you ‘d burn out extremely quickly, right? A motor experiences something comparable. This added pressure triggers the motor to also draw too much current from the power supply.

This excessive current is where the genuine difficulty starts for the motor. It makes the motor get too hot. If a motor gets as well warm, its interior parts, especially the winding, can be badly damaged. This is why understanding motor overload is so critical. It’s the main reason we see motor failure. An overload occurs when the motor is constantly pushed past its developed functional limits, making it work more challenging.

The major objective of any kind of excellent motor control system is to stop the motor from reaching this harmful state. If the motor draws more electrical current than it’s rated for, an overload problem is triggered. This can promptly bring about significant damage to the motor if the situation isn’t corrected. We always wish to ensure the load on the motor are proper.

So, exactly how do we stop this nasty motor overload from ruining our hardworking electric motor? This is where the trusty overload relay action is. An overload relay imitates a specialized bodyguard for your motor. It constantly monitors how much current the motor is utilizing.

If the relay finds that the motor is drawing in too much current (an overcurrent scenario), it takes immediate action. The overload relay will trip. “Tripping” implies it disrupts the control circuit, which subsequently informs the motor starter to cut off power to the motor. This important activity aids to safeguard the motor from obtaining alarmingly hot and experiencing permanent damages due to excess current. Lots of overload relays are utilized as a crucial component of a motor controller arrangement.

There are numerous sorts of these protective relay gadgets. Some are thermal overload relays, which react to the warmth produced by excess current. Others are more advanced, like digital overload relays or magnetic overload relays. Despite their distinctions, they all share the very same important task: to identify overload conditions and stop the motor to prevent damages due to the overload condition. When the relay trips, it’s doing its work.

Your motor suddenly quit, and you learnt the overload relay did its task– it tripped. The huge inquiry is, why did this motor overload take place? There can be many factors. One really typical cause is that the load on the motor were merely too high for an extended period. This is what we commonly describe as persistent motor overloading. It’s like the motor is stuck in a state of continuously needing to function tougher than it should.

In some cases, the source of the overload is a short-lived issue. Perhaps something got jammed in the machinery that the motor powers. This can create an abrupt, unanticipated overload situation. In such instances, having the overload relay to trip is specifically what you desire, as it guards the motor from immediate harm. These brief bursts of overloads are less damaging if infrequent.

However, if you discover your motor overload relay tripping repeatedly, that’s a clear warning indicating a deeper issue. While some could call this nuisance tripping, it’s commonly not a nuisance whatsoever; it’s a relentless caution from your motor. It means the root cause of the overload requires to be determined and taken care of. Constant tripping, also if the relay resets, still puts tension on the motor and can ultimately lead to motor failing. You require to examine what triggers the overload relay to keep triggering.

Yes, undoubtedly! There are different types of overload that can affect your motor, and it’s rather valuable to understand them. The two major groups are mechanical overload and electrical overload.

A mechanical overload takes place when the device or equipment that the motor is driving ends up being also hard to transform or relocate. Picture a pump that’s developed to relocate water unexpectedly attempting to pump thick mud– that would certainly place an enormous pressure on the spinning shaft of the motor. This requires the motor to function much harder than normal, creating it to draw more electrical current and potentially get too hot.

An electrical overload, on the other hand, is usually related to troubles with the power supply that feeds the motor, or electric faults within the motor itself. For example, if the voltage supplied to the motor is constantly too low, the motor could try to compensate by attracting more current, which leads straight to an overload problem. Both mechanical and electrical kinds of overload can create damages and set off an overload device like an overload relay to trip.

Absolutely, it can! The high quality of the power supply is unbelievably vital for the health and wellness and performance of your motor. If the source of power isn’t providing the motor with the correct kind or quantity of electrical energy, you can absolutely face motor overload problems. In my experience, checking the power source input is among the primary steps when a motor begins acting up.

Consider it this way: the motor needs a stable, reliable stream of power to do its task properly. If the power supply is unsteady, weak, or “dirty” (meaning it has fluctuations or noise), the motor could struggle. It might attempt to pull even more electrical current than it’s developed for to compensate. This excessive current then causes the motor to get too hot, and that’s specifically when the overload relay should interfere to protect the motor.

Problems with the power supply can include constantly low voltage, unusually high voltage, and even an unbalanced voltage if you’re managing a three-phase motor. Any one of these problems that trigger unsteady power can create a motor to run inefficiently and ultimately overload. A good, stable power supply, provided with an appropriately sized power cable, is fundamental for a pleased, healthy and balanced motor.

Voltage plays a very significant function in whether a motor experiences an overload. You can think of voltage as the “pressure” that pushes electric current via the motor. If this stress– the voltage — is too low (a condition occasionally called undervoltage), the motor won’t get sufficient power to perform its task quickly. To compensate, the motor will certainly attempt to attract more electrical current.

When a motor draws too much current due to low voltage, its winding can rapidly get too hot. This is a timeless reason for the overload. The motor control system, that includes the overload relay, is developed to detect this circumstance and should remove power to the motor. If the motor is being provided with constantly inaccurate voltage, it can result in considerable motor damage over time.

Alternatively, high voltage (overvoltage) can additionally be detrimental. It can force too much current with the motor winding, once again leading to overheat and motor overload. So, the motor requires the appropriate voltage as specified by its supplier– not too high, and not too low. It’s like the story of Goldilocks; the voltage requires it to be “ideal” for ideal functional efficiency and to avoid motor overload.

Yes, mechanical overload and electrical overload are certainly various, although both can ultimately trigger a motor overload relay to trip. Comprehending this difference is vital to locating the true root cause of the motor problem.

A mechanical overload indicates that the motor is attempting to drive a load that is too heavy, or something in the driven equipment is obstructed or binding. The trouble stems with the physical load the motor is connected to, not initially with the motor itself or its power supply. For example, a conveyor belt that has a seized bearing will produce a mechanical overload for the motor attempting to relocate. This compels the motor to work more difficult.

An electrical overload, on the other hand, is typically due to concerns with the electric energy being provided to the motor or an electric mistake within the motor’s elements. This might be because of inaccurate voltage from the source of power, a failing winding inside the motor, or even a damaged power cable. So, with a mechanical overload, the motor is normally healthy, however the job is too demanding. With an electrical overload, the motor may have an inner electrical problem, or the power it’s obtaining is malfunctioning. Both mechanical and electrical concerns can cause the motor to overload.

Ah, worn bearings! These seemingly little elements can cause surprisingly large issues for a motor. Bearings are crucial due to the fact that they allow the motor shaft to rotate efficiently with minimal friction. If these bearings become worn or harmed, they create significantly a lot more friction.

This increased friction means the motor has to function more challenging simply to transform its own shaft, also prior to its attempts to relocate any type of exterior tons. This extra effort forces the motor to draw even more electric current from the power supply. And as we have actually reviewed, when a motor draws too much current, it brings about the motor heating up, which can after that cause a motor to overload. The bearings on the shaft have to remain in great condition to stop this.

Changing worn or damaged bearings is typically a reasonably uncomplicated solution that can stop a lot more severe and pricey motor damages. If you start listening to uncommon grinding or roaring noises from your motor, or if it appears to be struggling or getting uncommonly hot, it’s wise to inspect the condition of the bearings. It’s an extremely common reason for the overload when an overload relay keeps tripping. Disregarding a poor bearing can swiftly cause motor failing.

When a motor overload takes place, a number of points occur within the motor that can result in problems. The most immediate impact is that the motor draws far too much current. This excess current after that streams with the motor’s winding. The winding is basically coils of wire, and when an excessive amount of electrical current goes through these wires, they create a lot of warmth.

This warmth is the primary opponent within the motor throughout an overload. If the winding gets as well warm, the insulation product around the wires can melt, degrade, or perhaps burn. This malfunction of insulation can create short circuits within the motor, resulting in permanent damages to the motor. The delicate equilibrium of the magnetic field that makes the motor revolve can also be disrupted. This is precisely why an overload protection device is so essential.

The overload relay is particularly designed to spot overload conditions, typically by sensing this excessive warmth (when it comes to a thermal overload relay) or by directly determining the excess current (an overcurrent condition). When it discovers an overload, it acts to remove power and thus safeguard the motor prior to extreme damage due to overheating. Also seemingly small short bursts of overloads, if they happen frequently, can cumulatively shorten the life of a motor. The purpose of all overload procedures is to prevent this hazardous heating.

For a three-phase motor, there are a number of telltale signs and symptoms of motor overload that you can keep an eye out for. Among the most usual signs is the motor running visibly hotter than normal. In extreme overload conditions, you may also discover a unique burning odor coming from the motor. One more clear indicator is if the motor starter constantly trips its overload relay.

You may additionally notice the motor making uncommon sounds, such as a loud humming, whining, or a stressing noise, suggesting it needs to function harder. If the motor is running however appears to lack its typical power or performs at a lowered rate, this might likewise aim in the direction of an overload. Occasionally, a tripped breaker or a blown fuse in the main power source circuit can be a sign and symptom, as this takes place when the motor draws too much current flowing with the circuit. Various other issues that trigger motor overload in three-phase systems can include misalignment of the motor shaft.

To get a much more definitive answer, you can use a multimeter with a clamp attachment to carefully measure the electrical current flowing to the motor on each of the three phases. Contrast these analyses fully load amperage (FLA) rating on the motor’s nameplate. If the gauged current is substantially higher than the FLA, then you likely have an overload. For a three-phase motor, it’s additionally important that the current is relatively well balanced across all three phases. A significant imbalance can also cause the motor to overheat and overload, even if the overall current isn’t excessively high.