Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

12V DC motor is a small, simple part, but it is the secret hero in so many things we use. In this article, I am going to explain what this great electric motor is used for. You will be surprised to learn how much you use a 12v dc motor to make your life easier. This guide will show you all about it, one step at a time.

Let’s begin with the simple facts. What is a 12v dc motor? You can think of it like a tiny engine. It runs on a special kind of power. The “12V” part tells you the voltage it needs to work. It needs 12 volts of direct current (DC) power. This is the kind of power that comes from batteries. That is why the 12v dc motor is great for things you can carry around.

Its main job is very simple. This motor used in many gadgets has one big job to do. It is made to convert electrical energy into mechanical movement. It takes in electricity and turns it into a spinning motion. This simple job makes the 12v dc motor useful in many different ways. It is a key piece of technology. It can power many things, from a toy car to a big machine. The low voltage also makes it safe and easy to work with. That is why I enjoy using it for my own projects.

I remember when I first opened up a 12v dc motor. I was very interested in the parts inside. It looked difficult, but the way it works is pretty simple. A 12v dc motor uses magnets to create movement. Inside, there are a few important parts. You can look at pictures on Wikipedia, but I will give you the easy version. The outside part is the stator. It usually has permanent magnets. The inside part that spins is the armature. The armature is made of a wire coil called a winding.

When you send direct current into the armature’s winding, the winding turns into an electromagnet. This makes a magnetic field. This new magnetic field then pushes away from the magnetic field of the permanent magnets. This pushing and pulling makes the armature rotate. A small part called a brush keeps sending power to the winding while the armature is spinning. The way these magnetic fields generates movement creates the smooth spinning that we use to power so many things. This process of turning electrical energy into mechanical energy is the secret of every 12v dc motor. The whole system is made to generate this force and do it well.

Do you ever wonder how your car’s windows move when you push a button? I have. The answer is usually a good old 12v dc motor. The automotive industry really likes these motors. The reason is simple. A car’s battery gives 12-volt DC power. This makes the 12v dc motor a perfect choice. You do not need special tools to change the power. They fit in perfectly.

These motors are the hard-working parts that make many things in your automobile work. They power your electric windows, making them go up and down. They run the pump that sprays your windshield washer fluid. They also make your windshield wipers move. Many cars also have a 12v dc motor to adjust the seats and side mirrors. The reliability and simple technology of a 12v dc motor make it great for the automotive sector. They give enough power for these jobs, and they do not use up the car’s battery. The use of a 12v dc motor is a big part of how modern cars are made.

Yes, you can! You most likely use something with a 12v dc motor in it every day and you might not even know it. Many household appliances use them. This is especially true for the small ones that you can carry. For example, my children have toy remote-control cars, and each one gets its power from a small 12v dc motor. The low voltage makes them safe to use in toys.

It doesn’t end there. Just look in your bathroom. Do you own any electric toothbrushes? That fast spinning comes from a tiny 12v dc motor. This small electric motor is built for high speed to make sure it cleans well. Other devices like small fans for your desk, vacuums you can carry, and even some tools in the kitchen use a 12v dc motor. They have good efficiency and are small. This makes them a smart choice for any appliance where you need to save space and power. A 12v dc motor is a very common part in many small household items.

This is the part that is really fun for me. My love for robotics is the reason I got interested in the 12v dc motor. In the fields of automation and robotics, being able to control things exactly is very important. A 12v dc motor gives you that kind of control. It is easy to manage its speed and position. This is very important for these kinds of jobs.

You can think about the big robotic arms in factories. Many of them use a strong 12v dc motor, or even many of them, to move with precision. For smaller projects, people who do this as a hobby use a 12v dc motor to make their own robots. They are also put inside CNC machines to help move a cutting tool to the right place. In large storage buildings, you can see 12v dc motors making conveyor belts run, which move boxes from one place to another. The way they enable precise movement makes the 12v dc motor a tool they cannot work without in the automation industry. These motors help robotic arms and conveyor belts work correctly.

For medical devices, things need to be reliable. This means they must work every time. The 12v dc motor provides this kind of reliability. Its simple setup and trusted technology make it a safe option for medical equipment. Many portable medical devices use a 12v dc motor. This is because they can work with batteries, which makes them easy to carry around.

For instance, a 12v dc motor can power a pump that gives medicine to a person at a very exact speed. They are also the power behind many tools used in surgery that need very precise, controlled moves. You can also find a 12v dc motor in an electric wheelchair. It helps give people the ability to move around. A wheelchair needs a motor that has good torque to go up hills, and a 12v dc motor can do that. Improvements in medical devices often happen because of better motors. The 12v dc motor plays a very important part in that. This type of motor used in a wheelchair must be very dependable.

Picking the right 12v dc motor might look hard. But it is really about finding the right motor for what you want to do. I always ask myself three things: How fast does it need to spin? How much force does it need to have? And how much power should it save? The answers help you find the right 12v dc motor.

Here is an easy table to help you think about it:

| Feature | What It Means | Good For… |

|---|---|---|

| Speed | How fast the motor’s shaft spins (in RPM) | Fans, electric toothbrushes, toy cars |

| Torque | The turning force the motor can make | Wheelchair, robotic arms, car windows |

| Power | The total strength of the motor (Speed x Torque) | Lifting heavy items, conveyor belts |

| Efficiency | How well it changes electricity to movement | Things that use batteries, like a wheelchair |

Before you get a 12v dc motor, look at its details for speed, torque, and power. This will make sure it works the best way it can for your usage. A good parts provider will show all of this information for every 12v dc motor they have.

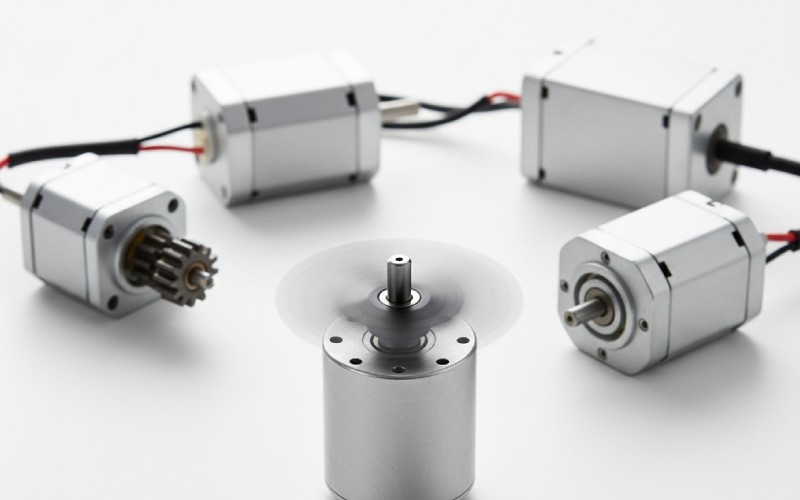

As you learn more about the world of the 12v dc motor, you will see the words “brush” and “brushless.” I was also confused by this at first. They both do the same job. But they do it in ways that are a little different. The biggest difference is in how the power is sent to the armature winding. You can get a lot of technical details from Wikipedia, but this is the simple version.

A normal 12v dc motor has a small carbon piece called a brush. The brush touches the part of the armature that is spinning to give it power. This design is easy to make and not expensive. But, the brush can get worn out after a while. A brushless dc motor is a newer type of technology. It uses electronics and not a brush to send the power. This means no parts are rubbing on each other. A brushless dc motor usually has better efficiency, a longer lifespan, and is quieter. The downside is that it is more complicated and often costs more than a 12v dc motor with a brush.

Knowing about speed and torque is the most important part of understanding the 12v dc motor. You can think about it like this: speed is how fast you can do a job, and torque is how much strength you have to do it. A 12v dc motor can be made to have a high speed and a low torque. Or it can have a low speed and a high torque. It is hard to get a lot of both in one simple 12v dc motor.

For example, the 12v dc motor in a small fan has to have a high speed. This is so it can move a lot of air. It does not need a lot of torque since air is not heavy. But, the 12v dc motor in an electric wheelchair needs to have a high torque. It has to create a strong spinning force to move the weight of a person, especially up a hill. The speed is not as important as the raw power. Many machines use gears with a 12v dc motor. The gears help change the amount of speed and torque. Because it can be changed in this way, it lets one type of electric motor be used in various applications.

I think the future for the 12v dc motor looks very good. Our world tries to be better at saving energy and using more automation. Because of this, the need for these small, strong motors will get bigger. The technology that is inside a 12v dc motor is always getting better. They are getting smaller, stronger, and have better efficiency than before. These improvements create new things we can do with them.

We will start to see the 12v dc motor have a bigger part in technology that helps the earth. For example, think about small water pumps that run on solar power or smart home systems that use very little power. Putting a 12v dc motor into more things we use every day will keep making our lives easier. From complex medical devices to easy household items, the 12v dc motor is a piece of technology that will be around for a long time. Its simple design and great functionality make sure that the 12v dc motors are widely used for many more years.

To finish, I want to give you a few important points to remember about the great 12v dc motor: